مركز تحويل عالي السرعة ثنائي المحور للعمل المعدني عالي التحمل

- برغي كروي عالي الدقة

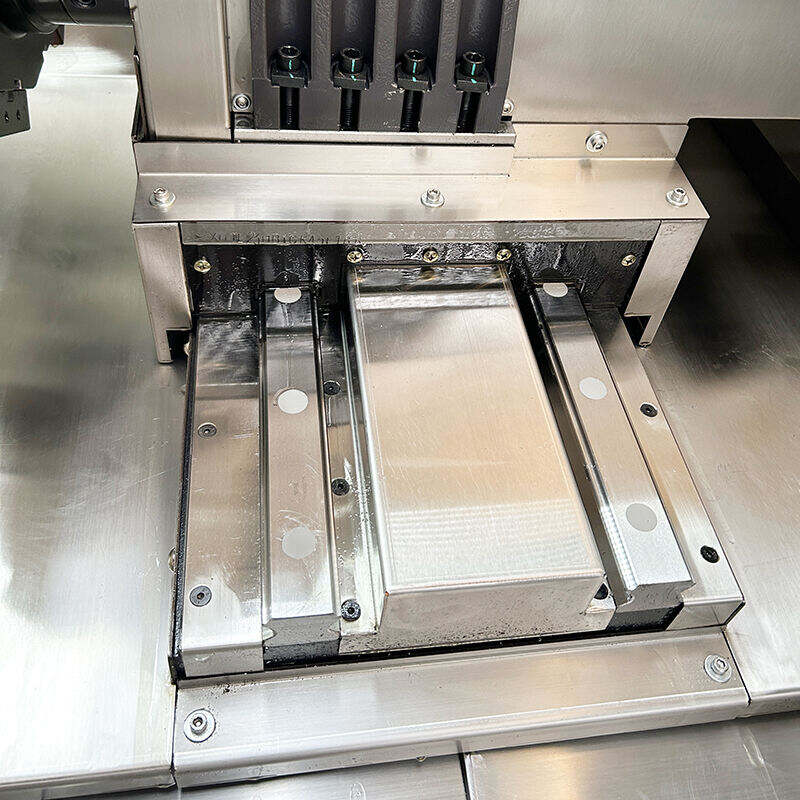

- دليل خطي دقيق عالي

- برج مزود بـ 12 محطة

- مشفر حلقي مغناطيسي

- ذيل هيدروليكي للبرمجة

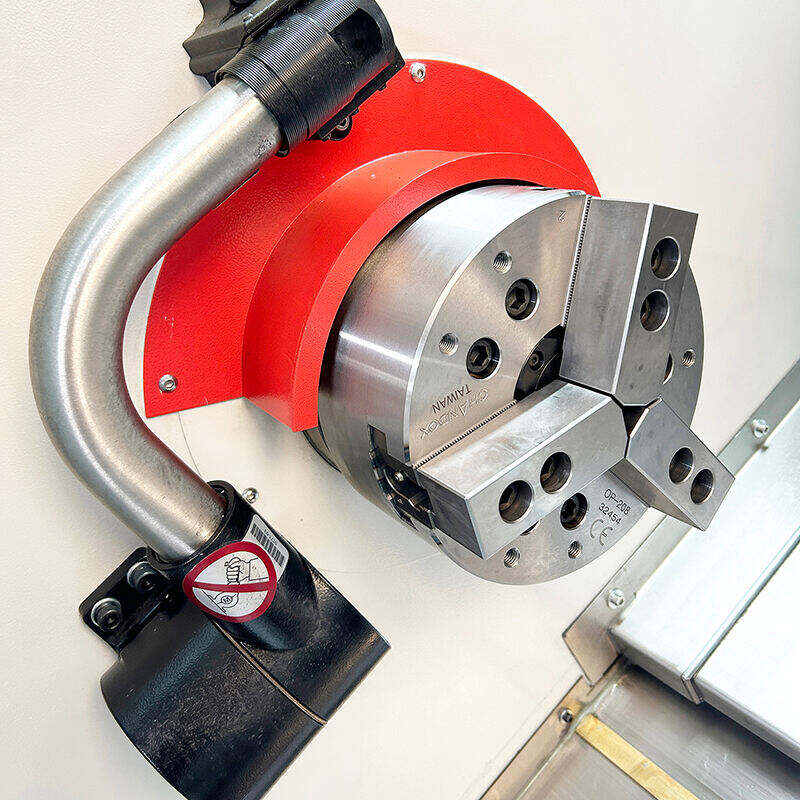

- A2-6 فولدر للخدمات الثقيلة

- A2-5 الفولاذ الفرعي

المقدمة

النظام الكهربائي مركز تحويل عالي السرعة ثنائي المحور تم تصميم آلة CNC من DONGS لتحقيق كفاءة عالية ودقة وتنوع في تطبيقات تشغيل المعادن. تم تصميم هذه الآلة الحديثة للتعامل مع العمليات عالية التحمل وتحسين عمليات الإنتاج، مما يجعلها مثالية للصناعات التي تتطلب أوقات استجابة سريعة وتصنيع دقيق. بفضل تكوينها ثنائي المغزل، يوفر مركز التحويل هذا قدرات تصنيع مستمرة، مما يسمح بزيادة الإنتاجية وتقليل وقت التوقف.

يجمع مركز الدوران هذا بين موثوقية الأداء عالي السرعة وتقنية CNC المتقدمة لتقديم نتائج استثنائية في إنتاج أجزاء معقدة بتفاوتات ضيقة. سواء كنت تعمل مع مجموعة متنوعة من المعادن أو تبحث عن أسرع دورة إنتاج لدفعات كبيرة، فإن مركز الدوران ثنائي المغزل يضمن أعلى جودة في كل عملية.

الميزات الرئيسية:

- تصميم المحور المزدوج: يعمل على زيادة الإنتاجية من خلال السماح لأداتين بالعمل في وقت واحد، مما يقلل من وقت التصنيع ويزيد الإنتاجية.

- التصنيع عالي السرعة: مُصمم للتعامل مع العمليات عالية السرعة، مما يضمن الدقة مع الحفاظ على أوقات الدورة السريعة.

- تكنولوجيا CNC المتقدمة: مجهزة بأحدث أدوات التحكم CNC لتحسين الدقة والبرمجة السهلة والتكامل السلس في خطوط الإنتاج الحديثة.

- دقة عالية التحمل: مثالي للأجزاء التي تتطلب تحمّلات ضيقة وتشطيبات عالية الجودة، مما يضمن الاتساق في كل عملية إنتاج.

- بناء قوي: تم تصنيعها من مواد قوية لتحمل العمليات الشاقة وضمان الأداء طويل الأمد حتى في ظل الظروف الصعبة.

- واجهة سهلة الاستخدام: يسهل تشغيل الماكينة وبرمجتها، مما يقلل من وقت التدريب ويزيد من كفاءة المشغل.

- مُغيّر الأدوات التلقائي (ATC): يسهل تغيير الأدوات بسرعة، مما يعزز كفاءة الماكينة وتنوعها في عمليات التصنيع المختلفة.

- الأداء الموفر للطاقة: تم تصميمه لتقليل استهلاك الطاقة مع الحفاظ على التشغيل عالي السرعة، مما يجعله خيارًا فعالاً من حيث التكلفة للاستخدام على المدى الطويل.

التطبيقات:

- صناعة السيارات: مثالي لإنتاج مكونات عالية الدقة مثل كتل المحرك، والأعمدة، وأجزاء السيارات المهمة الأخرى.

- تصنيع الطيران والفضاء: مثالية لتصنيع الأجزاء المعقدة التي تتطلب دقة وتسامحًا استثنائيين، بما في ذلك شفرات التوربينات والمكونات الهيكلية والمزيد.

- أجزاء الآلات الثقيلة: مناسب للتصنيع على نطاق واسع للأجزاء المعقدة والثقيلة المستخدمة في آلات البناء والصناعة.

- صناعة النفط والغاز: يتعامل بكفاءة مع إنتاج الأجزاء المتينة وعالية الأداء مثل الصمامات والأنابيب والشفاه للتطبيقات الحرجة.

- تصنيع الأدوات والقوالب: توفر سرعة عالية ودقة عالية في التشغيل للأدوات والقوالب والقطع في مختلف القطاعات الصناعية.

- أعمال المعادن العامة: متعدد الاستخدامات بما يكفي لمجموعة واسعة من تطبيقات تشغيل المعادن، بما في ذلك الخراطة والثقب والتشطيب للمعادن مثل الفولاذ والألمنيوم والتيتانيوم.

| سعة | وحدة | TCK52DYS | |

| المسافة بين المراكز | مم | 900 | |

| حجم الفكين | حبر | 8/6 | |

| ماكس، ألقِ على السرير | مم | 670 | |

| أقصى. التأرجح على الزلاجة العرضية | مم | 400 | |

| عرض السكة الحديدية الخطي | مم | 45/45 | |

| السفر | |||

| التقاطع السريع في محور X | م/دقيقة | 24 | |

| التقاطع السريع على المحور Z | م/دقيقة | 24 | |

| مسافة سفر محور X | مم | 260 | |

| مسافة سفر محور Z | مم | 800 | |

| سفر المحور Y | مم | ±50 | |

| الملف الرئيسي | الرئيسية A2-6 | فرعي A2-5 | |

| السرعة القصوى للمحور | دورة في الدقيقة | 4200 | 5000 |

| ماكس قوة المروحة | كيلو واط | 22 | 15 |

| رأس المغزل | - | الرئيسية A2-6 | فرعي A2-5 |

| سعة الشريط | مم | 52 | 46 |

| (تورت) | |||

| رقم محطة الأدوات | - | 12 | |

| نوع البراجة | - | بي ام تي 55 | |

| أداة دوارة | دورة في الدقيقة | 5000/4000 | |

| المساندة | |||

| قطر الريش | مم | / | |

| السفر بالريشة | مم | / | |

| سفر المخرطة | مم | المغزل الفرعي 650 | |

| مخروط الذيل | - | MT5 | |

| الأبعاد | |||

| حجم التعبئة | م | 3.7 | |

| العرض | م | 2 | |

| الارتفاع | م | 2.5 | |

| الوزن الصافي | كجم | 5 |

أسئلة شائعة

س: من نحن؟

ج: نحن رائد في مجال الابتكار في مجال معدات CNC. نحن صانع متخصص في إنتاج مراكز التدوير المتوسطة والكبيرة الكفاءة، ولاثات CNC المائلة، ولاثات CNC المستوية، ومراكز التصنيع، ولاثات عمودية. ندعو بشدة شركاء استراتيجيين عالميين لمناقشة اتجاهات الصناعة معًا.

س: كيف يمكنني اختيار الجهاز الأكثر ملاءمة؟

ج: يرجى إخبارنا بالمواصفات الخاصة بك ويمكننا اختيار أفضل نموذج لك، أو يمكنك اختيار النموذج الدقيق.

س: هل لديك مصنع حقيقي؟

نعم، نحن شركة تصنيع لآلات الخراطة CNC في مدينة تينغتشو، مقاطعة شاندونغ. لدينا فريق تقني محترف وفريق مبيعات وفريق خدمة ما بعد البيع.

ما الخدمات التي يمكننا تقديمها؟

شروط التسليم المقبولة: FOB، CFR، CIF، EXW؛ العملات المقبولة للدفع: دولار أمريكي، يوان صيني؛ أنواع الدفع المقبولة: T/T، L/C، ويسترن يونيون؛ اللغات المستخدمة: الإنجليزية، الصينية.

كيف نضمن الجودة؟

دائماً يتم إجراء عينات قبل الإنتاج الضخم؛ دائماً يتم إجراء الفحص النهائي قبل الشحن؛

لماذا يجب عليك شراء منتجاتنا بدلاً من موردين آخرين؟

نحن متخصصون في تصنيع هذه المنتجات لمدة 20 عامًا وقد حصلنا على شهادات ISO 9001، CE، وEAC.

هل يمكنكم تخصيص الجهاز؟

نعم، نقوم بدمج التصميم والتطوير مع المهندسين ذوي الخبرة والفنيين المتخصصين في التركيب.

هل يمكنني زيارة مصنعكم؟

أ: حسنًا، أنت مرحب بك جدًا.