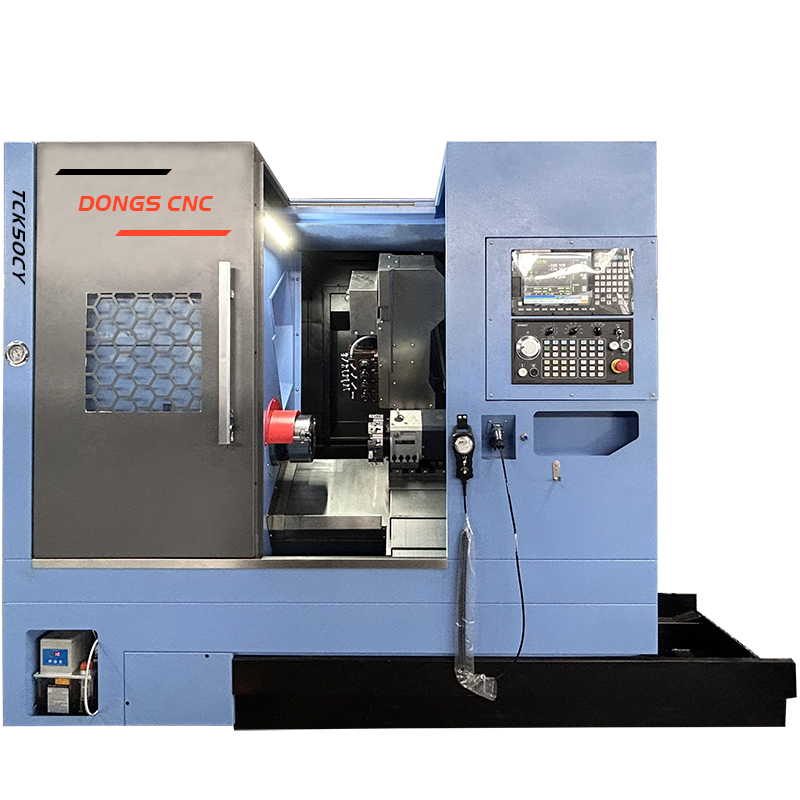

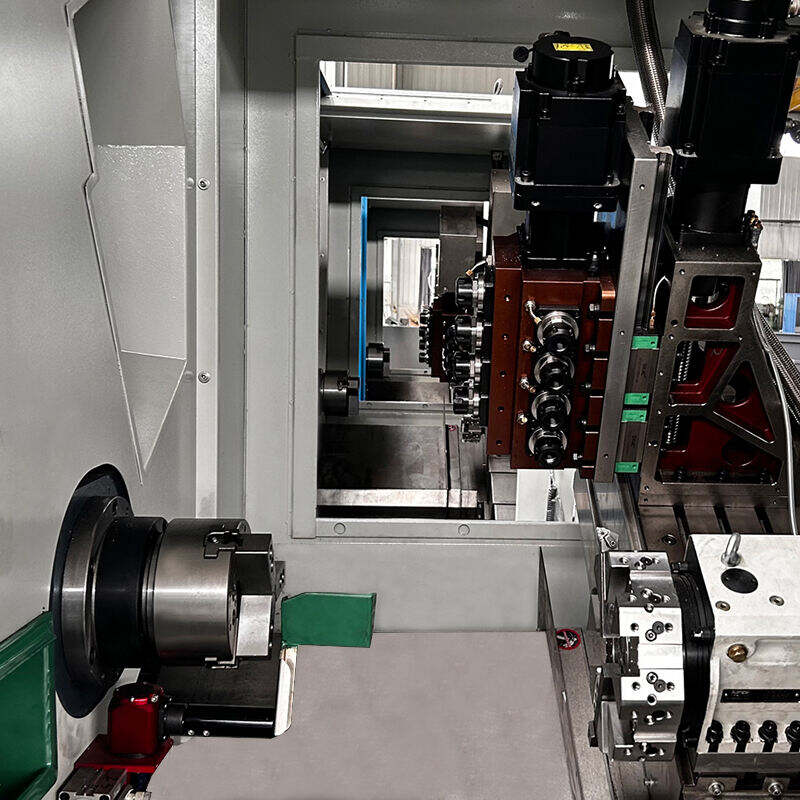

מרכזי חרטת CNC חסכוניים לייצור דיוק וייצור המוני

- מדריך ליניארי רולרי בעל דיוק גבוה

- בורג כדורי בעל דיוק גבוה

- מסב דיוק מיובא

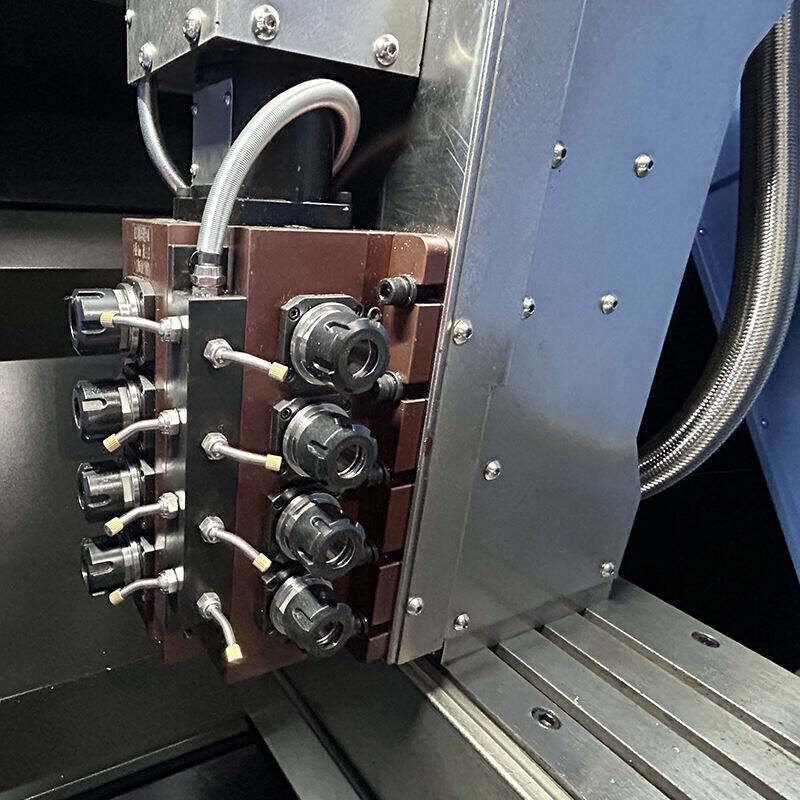

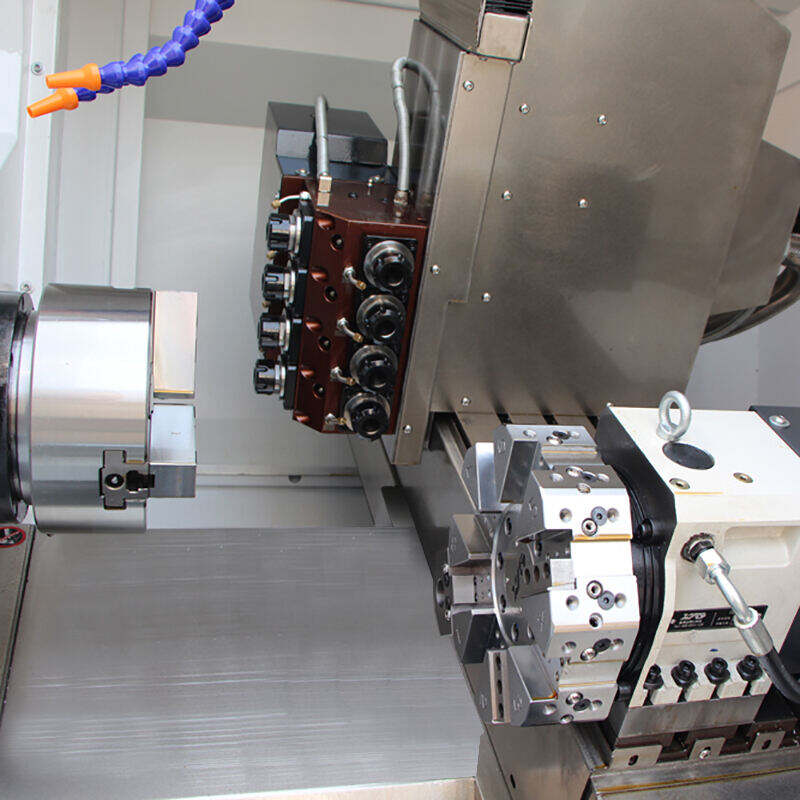

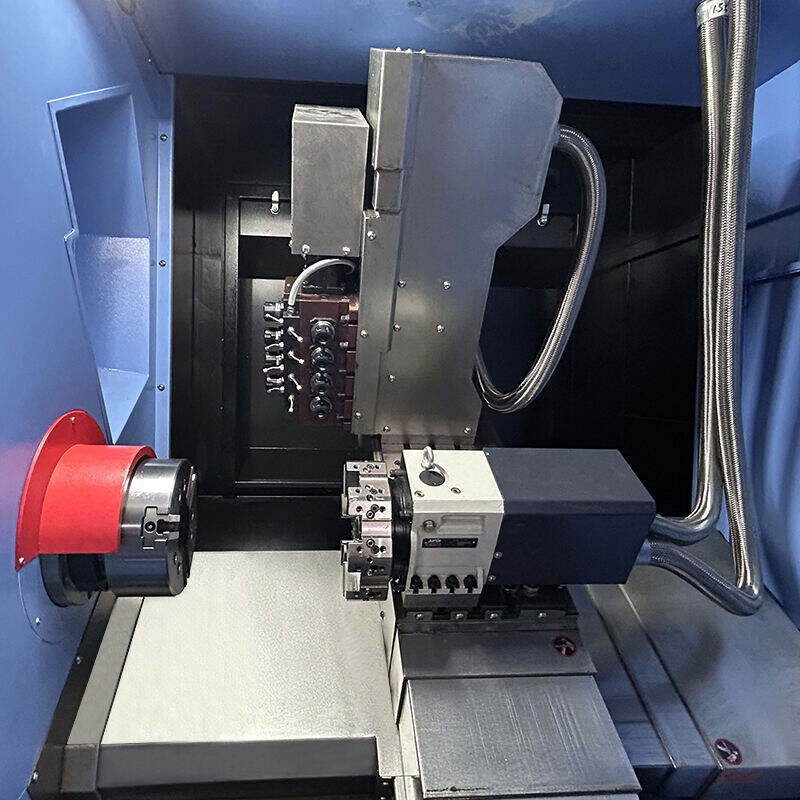

- מגדל-הדרו-הדרו-סרוואי של 8 תחנות

- חומרי חיים לקבוצה

- צ'אק הידראולי עם 8 מצבים

הקדמה

ה מרכזי חיתוך CNC חסכוניים מיועדים לייצור המוני בדיוק גבוה במגוון מגזרים תעשייתיים. בשילוב סבירות עם טכנולוגיית עיבוד שבבי מתקדמת, מכונות אלו מספקות ביצועים יוצאי דופן, מה שהופך אותן לאידיאליות עבור פעולות ייצור קטנות וגדולות כאחד. מצוידים בתכונות חזקות, מרכזי המפנה מציעים קשיחות ואמינות מעולים עבור היישומים התובעניים ביותר, ומבטיחים תפוקה עקבית של חלקים באיכות גבוהה. בין אם מייצרים רכיבים עבור תעשיות רכב, תעופה וחלל או הנדסה כללית, מכונות אלו מבטיחות יעילות וחיסכון בעלויות מבלי להתפשר על האיכות.

תכונות מפתח:

- דיוק ואמינות גבוהים : מצויד במערכות בקרת CNC מתקדמות לתוצאות עיבוד עקביות ומדויקות.

- ביצועים יעילים במהירות גבוהה : מותאם לפעולות פנייה במהירות גבוהה, הפחתת זמני מחזור והגברת הפרודוקטיביות.

- בניית מטען כבד : בנוי לעמוד בעומסי עבודה כבדים, ומציע קשיחות ויציבות מעולים עבור יישומים תובעניים.

- ממשק בקרה ידידותי למשתמש : פקדים קלים לשימוש המבטיחים פעולה חלקה ומצמצמים את זמן אימון המפעיל.

- פעולה חסכונית : נועד להציע ביצועים מקסימליים במחיר תחרותי, אידיאלי עבור יצרנים קטנים וגדולים כאחד המעוניינים למזער את עלויות הייצור.

- רב-תכליתית עבור יישומים מרובים : מתאים לתעשיות שונות, מסוגל לעבד מגוון רחב של חומרים ממתכות ועד פלסטיק.

- אפשרויות כלי עבודה להתאמה אישית : תואם למחזיקי כלים ואבזרים שונים כדי לעמוד בדרישות עיבוד מגוונות.

- תכונות בטיחות מתקדמות : מצויד באמצעי בטיחות משופרים כדי להבטיח פעולות מאובטחות ולהגן על המכונה והמפעיל.

ת Pebahot:

- תעשיית הרכב : משמש לעיבוד רכיבים בעלי דיוק גבוה כמו חלקי מנוע, רכיבי תיבת הילוכים ומערכות בלמים.

- תעופה : אידיאלי לייצור חלקי תעופה וחלל מורכבים, כולל להבי טורבינה, רכיבי מנוע וחלקי מבנה.

- הנדסה כללית : עיבוד של מגוון רכיבים ליישומי ייצור שונים, לרבות גלגלי שיניים, פירים וביתונים.

- עיבוד מתכת : מתאים לייצור המוני של חלקי מתכת, מציע פרודוקטיביות גבוהה ועקביות עבור קבוצות גדולות.

- ייצור ביטחוני : עיבוד חלקים בעלי סובלנות גבוהה לציוד ומערכות צבאיות.

- ציוד רפואי : עיבוד שבבי מדויק של רכיבים למכשור ומכשור רפואי.

- אנרגיה מתחדשת : ייצור חלקים עבור טורבינות רוח, פאנלים סולאריים וטכנולוגיות אחרות של אנרגיה מתחדשת.

| תכונות | יחידה | TCK50CY |

| מקסימום להתנדנד מעל המיטה | מ"מ | φ510 |

| Max Swing Over Slide | מ"מ | φ200 |

| קוטר סיבוב מקסימלי | מ"מ | φ200 |

| סוג ראש ציר | - | A2-6 |

| קוטר ציר דרך חור | מ"מ | φ80 |

| קיבולת בר | מ"מ | 55/65 |

| מהירות סיבוב מקסימלית | סל"ד | 4200/3500 |

| הספק מנוע ראשי | קילוואט | 7.5-11 |

| צ'אק הידראולי | אינצ' | 8 |

| דיוק מיקום | מ"מ | ±0.01 |

| יכולת חזרה (X/Y/Z) | מ"מ | ±0.005 |

| מהירות סיבוב מקסימלית | סל"ד | 1000-4000 |

| מומנט חיתוך | ניוטון מטר | 10 |

| מהלך ציר X | מ"מ | 1100 |

| מהלך ציר Z | מ"מ | 550 |

| X/Z מהירות תנועה מהירה | מ/דקה | 24/24 |

| סוג מגדל | - | חומרי חיים לקבוצה |

| זמני שינוי הכלים הסמוכים | ש | 0.5 |

| מספר התחנה | - | 8 |

| אביב צ'אק | - | ER25 |

| מהלך ציר Y | מ"מ | ±220 |

| ממדים | מ | 2900*2000*2300 |

| משקל מכונה (בערך) | ק"ג | 3000 |

שאלות נפוצות

שאלה: מי אנחנו?

תשובה: אנו מנהיגי חדשנות בתחום ציוד CNC. אנו יצרן המהווה מרכז סיבובים ממוחשב למחזורים גדולים ובינוניים, טורנitos CNC במיטה משופתת, טורנitos CNC במיטה שטוחה, מרכזים לייצור וטורנitos אנכיים. אנו מזמינים בלב פתוח שותפים אסטרטגיים עולמיים לדון יחדיו בהגדרות התעשייה.

שאלה: כיצד אני יכול לבחור את המכונה המתאימה ביותר?

<tool_call>: ספר לנו את הפרטים והאנו נבחר עבורך את המודל הטוב ביותר, או שאתה תבחר את המודל המדויק.

שאלה: האם יש לכם מפעל ממשי?

<tool_call>: כן, אנו יצרן טורנitos CNC בעיר טנגצ'ואו, מחוז שנדונג. יש לנו צוות מקצועי של מהנדסים, מכירות ושירות לקוחות.

שאלה: אילו שירותים אנו יכולים להציע?

<tool_call>: תנאים של מסירה: FOB, CFR, CIF, EXW; מטבעות תשלום מקובלים: דולר אמריקאי, יין סיני; סוגי תשלום מקובלים: T/T, L/C, Western Union; שפות בשימוש: אנגלית, סינית.

שאלה: כיצד אנו מבטיחים איכות?

א: דגימות ייצור תמיד מתבצעות לפני ייצור מסיבי; בדיקה סופית תמיד מתבצעת לפני שליחה;

ש: למה כדאי לכם לקנות מאיתנו במקום מספקים אחרים?

א: אנחנו התמחנו בייצור מוצרים אלו במשך 20 שנה וקיבלנו את תעודת האיכות ISO 9001, תעודת CE ותעודת EAC.

ש: האם תוכלו להתאים את המכונה?

א: כן, אנחנו משלבים עיצוב ופיתוח, עם מהנדסים וטכנאיםperienced בעלי ניסיון.

ש: האם אני יכול לבקר במפעל שלכם?

א: טוב, אתה/את כל כך מוזמן.