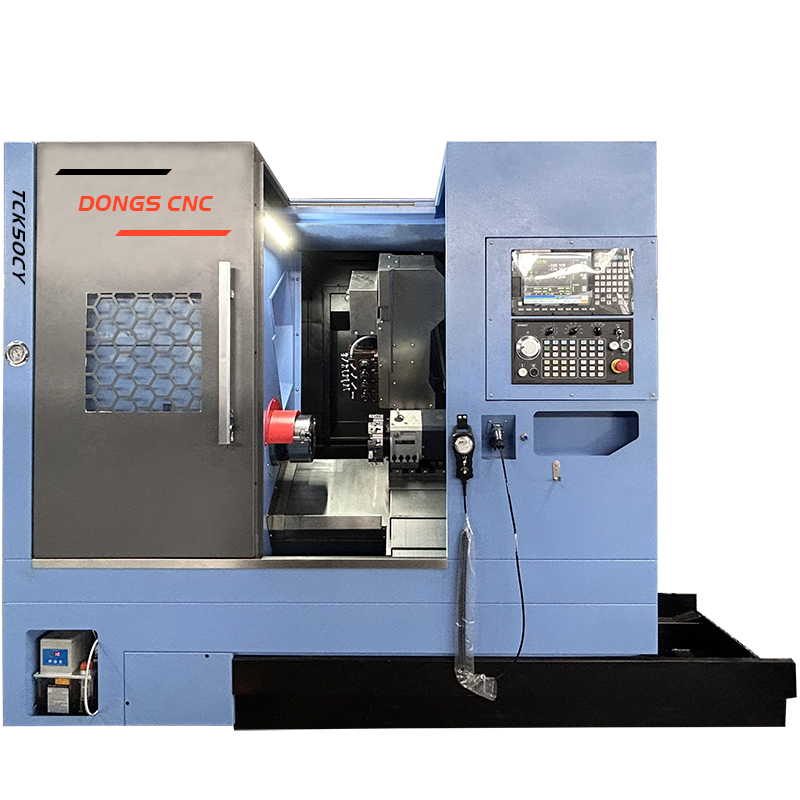

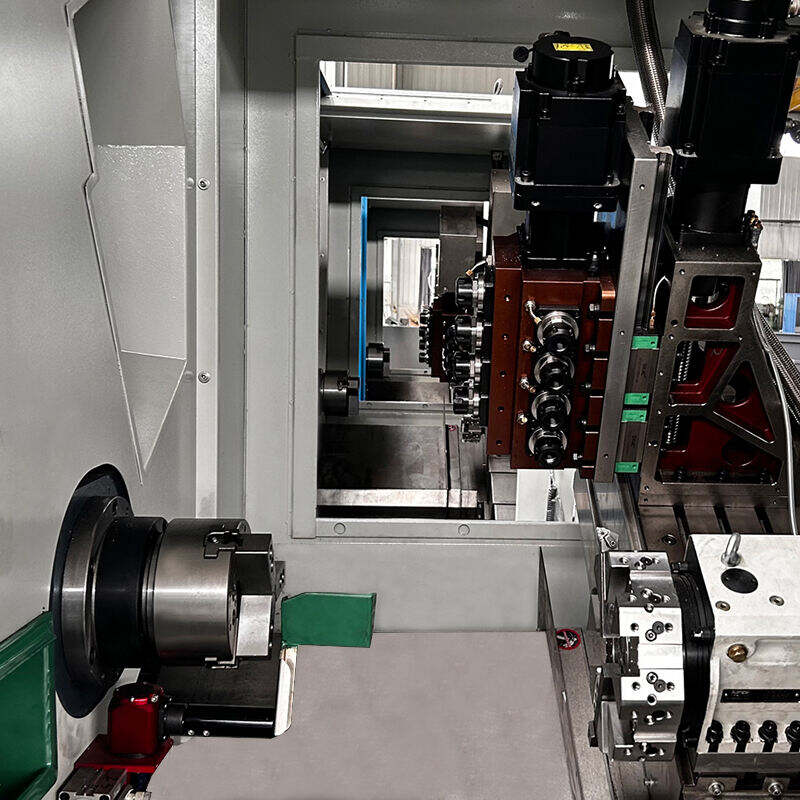

Ekonomiczne centra tokarskie CNC do precyzyjnej i masowej produkcji

- Wysokoprecyzyjny prowadnik liniowy rolkowy

- Wysokoprecyzyjna śruba kulowa

- Importowane łożysko precyzyjne

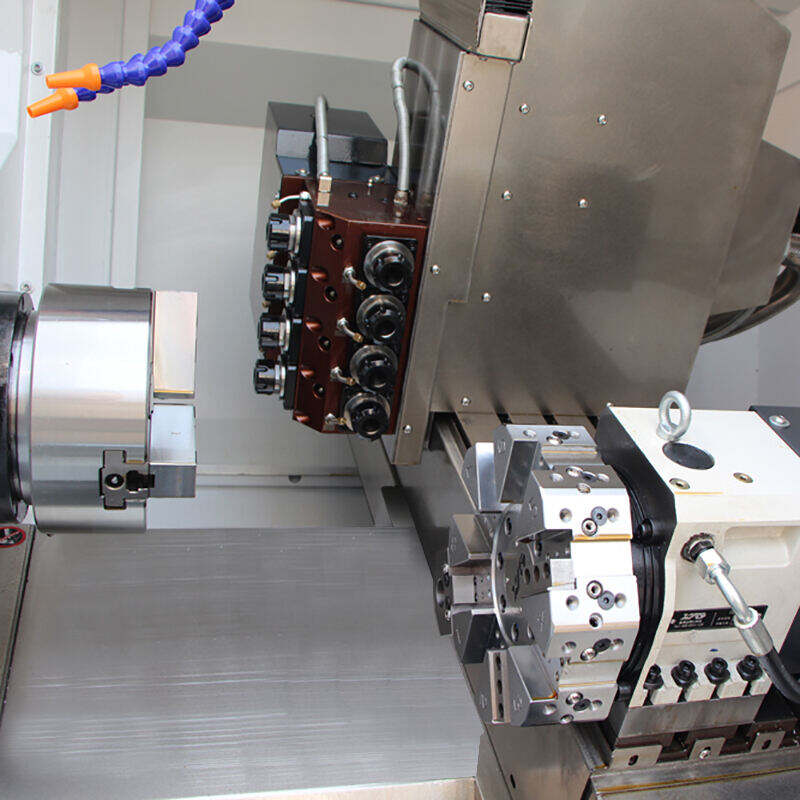

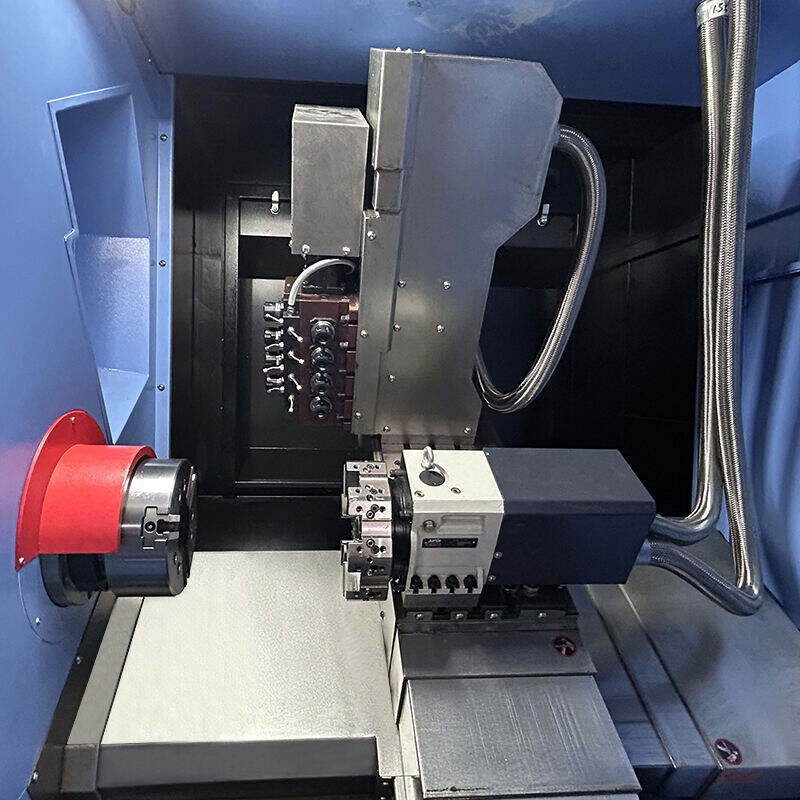

- 8-stacjonarna wieża serwohydrauliczna

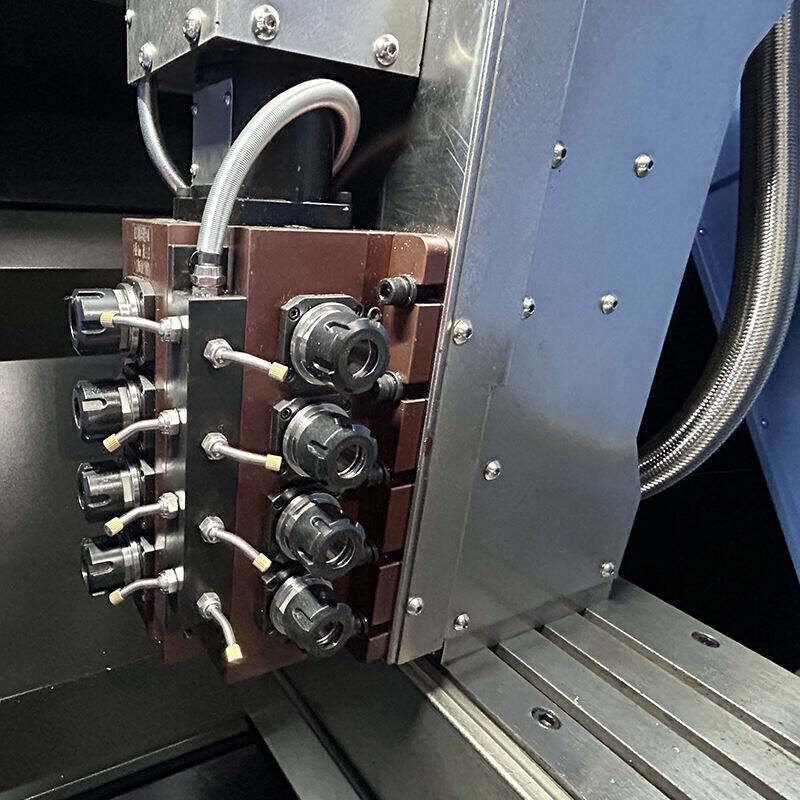

- Grupa żywych narzędzi

- 8-pozycyjny chwytak hydrauliczny

Wstęp

The Ekonomiczne centra tokarskie CNC są przeznaczone do produkcji masowej o wysokiej precyzji w różnych sektorach przemysłu. Łącząc przystępną cenę z zaawansowaną technologią obróbki, maszyny te zapewniają wyjątkową wydajność, dzięki czemu idealnie nadają się zarówno do małych, jak i dużych operacji produkcyjnych. Wyposażone w solidne funkcje, centra tokarskie oferują doskonałą sztywność i niezawodność w najbardziej wymagających zastosowaniach, zapewniając stałą produkcję wysokiej jakości części. Niezależnie od tego, czy produkujesz komponenty dla przemysłu motoryzacyjnego, lotniczego czy inżynieryjnego, maszyny te gwarantują wydajność i oszczędność kosztów bez uszczerbku dla jakości.

Najważniejsze funkcje:

- Wysoka precyzja i niezawodność : Wyposażone w zaawansowane systemy sterowania CNC zapewniające spójne i dokładne wyniki obróbki.

- Wydajna praca przy dużej prędkości :Zoptymalizowany pod kątem szybkich operacji toczenia, skraca czas cyklu i zwiększa wydajność.

- Ciężki Budownictwo :Zaprojektowane tak, aby wytrzymywać duże obciążenia, oferują doskonałą sztywność i stabilność w wymagających zastosowaniach.

- Przyjazny dla użytkownika interfejs sterowania :Łatwe w użyciu elementy sterujące, które zapewniają bezproblemową obsługę i skracają czas szkolenia operatora.

- Kosztowo efektywna operacja :Zaprojektowane tak, aby zapewnić maksymalną wydajność przy konkurencyjnej cenie, idealne zarówno dla małych, jak i dużych producentów, którym zależy na zminimalizowaniu kosztów produkcji.

- Uniwersalny dla Wielu Zastosowań :Nadaje się do stosowania w różnych gałęziach przemysłu, umożliwia obróbkę szerokiej gamy materiałów od metali po tworzywa sztuczne.

- Opcje dostosowywania narzędzi :Kompatybilne z różnymi uchwytami narzędziowymi i przystawkami, co pozwala sprostać zróżnicowanym wymaganiom obróbki.

- Zaawansowane Funkcje Bezpieczeństwa : Wyposażone w ulepszone środki bezpieczeństwa, aby zagwarantować bezpieczną pracę oraz chronić maszynę i operatora.

Zastosowania:

- Przemysł motoryzacyjny :Stosowany do obróbki elementów o wysokiej precyzji, takich jak części silnika, elementy przekładni i układy hamulcowe.

- Lotnictwo i kosmonautyka :Idealny do produkcji skomplikowanych części lotniczych, w tym łopatek turbin, podzespołów silników i części konstrukcyjnych.

- Inżynieria ogólna :Obróbka mechaniczna różnorodnych komponentów dla różnych zastosowań produkcyjnych, w tym kół zębatych, wałów i obudów.

- Obróbka metali :Nadaje się do masowej produkcji części metalowych, zapewniając wysoką wydajność i powtarzalność dużych partii.

- Produkcja obronna :Obróbka mechaniczna części o wysokiej tolerancji dla sprzętu i systemów wojskowych.

- Sprzęt medyczny :Precyzyjna obróbka elementów urządzeń i instrumentów medycznych.

- Energia odnawialna produkcja części do turbin wiatrowych, paneli słonecznych i innych technologii energii odnawialnej.

| Specyfikacje | Jednostka | TCK50CY |

| Max huśtawka nad łóżkiem | Mm | φ510 |

| Max Swing Over Slide | Mm | φ200 |

| Maksymalna średnica toczenia | Mm | φ200 |

| Typ głowicy wrzeciona | - | A2-6 |

| Średnica otworu wrzecionowego | Mm | φ80 |

| Pojemność stołu | Mm | 55/65 |

| Maksymalna prędkość obracania | Obr/min | 4200/3500 |

| Moc głównego silnika | KW | 7.5-11 |

| Uchwyt hydrauliczny | Węzeł | 8 |

| Dokładność pozycjonowania | mm | ±0.01 |

| Powtarzalność (X/Y/Z) | mm | ±0.005 |

| Maksymalna prędkość obracania | Obr/min | 1000-4000 |

| Moment obrotowy cięcia | N.M | 10 |

| Przesunięcie osi X | Mm | 1100 |

| Przesunięcie osi Z | Mm | 550 |

| X/Z Szybka prędkość ruchu | M/min | 24/24 |

| Typ wieży | - | Grupa żywych narzędzi |

| Sąsiadujące czasy wymiany narzędzi | S | 0.5 |

| Liczba stacji | - | 8 |

| Wiosenny Chuck | - | ER25 |

| Przesunięcie osi Y | Mm | ±220 |

| Wymiary | M | 2900*2000*2300 |

| Waga maszyny (około) | Kg | 3000 |

FAQ

Q:Kim jesteśmy?

A:Jesteśmy liderem innowacji w dziedzinie urządzeń CNC. Jesteśmy producentem specjalizującym się w produkcji średnich i dużych, wydajnych centrów obróbkowych, skosnych obrabiarek CNC, płaskich obrabiarek CNC, centrów mechanicznych oraz pionowych obrabiarek. Szczerze zapraszamy globalnych partnerów strategicznych do dyskusji nad trendami branżowymi.

Q:Jak mogę wybrać najbardziej odpowiednią maszynę?

A:Proszę powiedzieć nam swoje wymagania, a my wybierzemy dla Ciebie najlepszy model, lub sam możesz wybrać dokładny model.

Q:Czy macie rzeczywisty zakład produkcyjny?

O: Tak, jesteśmy producentem obrabiarek CNC w mieście Tengzhou, w prowincji Shandong. Dysponujemy profesjonalnym zespołem technicznym, sprzedażowym i obsługi po sprzedarzy.

P: Jakie usługi możemy udzielić?

O: Akceptowane warunki dostawy: FOB, CFR, CIF, EXW; Akceptowane waluty płatnicze: USD, RMB; Akceptowane rodzaje płatności: T/T, L/C, Western Union; Używane języki: angielski, chiński

P: Jak gwarantujemy jakość?

O: Zawsze wykonujemy próbne próbki przed masową produkcją; zawsze przeprowadzamy ostateczną inspekcję przed wysyłką;

P: Dlaczego powinniście kupić u nas zamiast u innych dostawców?

O: Specjalizujemy się w produkcji tych produktów od 20 lat i otrzymaliśmy certyfikaty ISO 9001, CE oraz EAC.

P: Czy można dostosować maszynę?

O: Tak, integrujemy projektowanie i rozwój, posiadając doświadczonych inżynierów i techników montażowych.

P: Czy mogę odwiedzić waszą fabrykę?

A: Dobrze, bardzo Ci dziękuję.