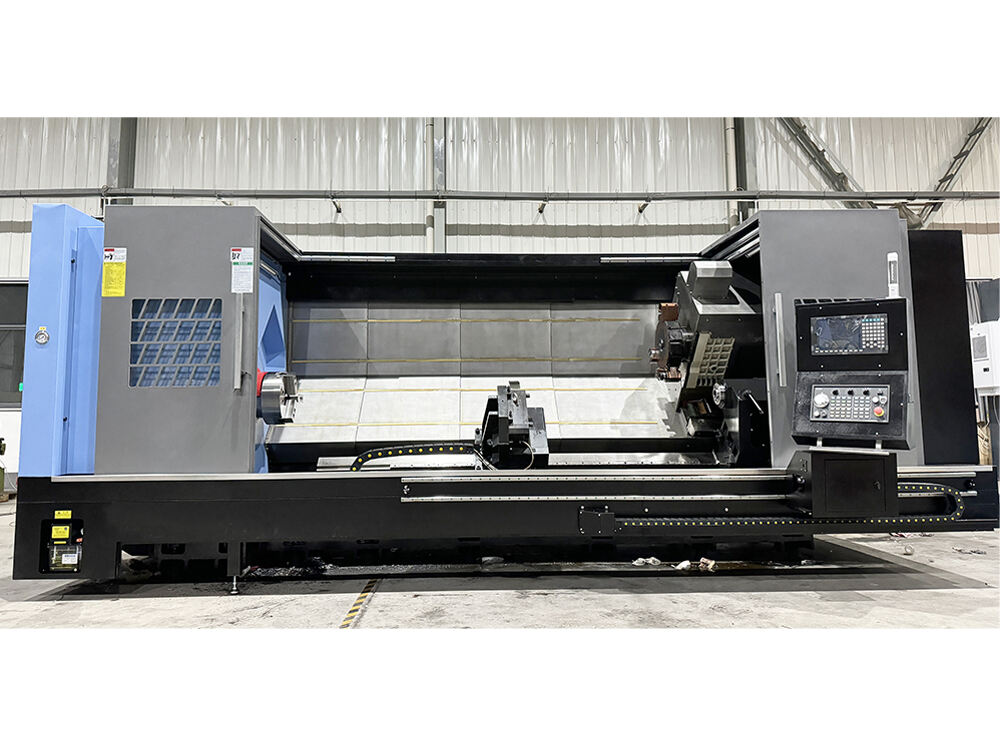

The use of remote technology in CNC lathes can significantly improve production efficiency

In recent years, as a highly automated machining equipment, the improvement of production efficiency of CNC lathes is crucial for modern manufacturing. By utilizing remote technology to improve production efficiency, the gap with advanced technology can be gradually narrowed.

1. By optimizing the software program of the CNC lathe, machining time can be reduced and machining quality can be improved. Thereby improving production efficiency

2. CNC lathes can use multi coordinate linkage to process complex parts without resistance. Secondly, CNC lathes have small limitations and can process different parts by adjusting the CNC program and corresponding parameters appropriately.

3. Correct operating skills and maintenance are crucial for ensuring the normal operation of CNC lathes, including regular inspection and maintenance of equipment, improving the quality of operators, and increasing production efficiency.

4. CNC lathes utilize computer technology and network communication technology to achieve remote monitoring and management, information collection, transmission, storage, query, display, and remote diagnosis of operating conditions. This enables open network monitoring services for the entire production cycle of CNC lathes, thereby improving after-sales service efficiency and contributing to the improvement of production efficiency and product quality.