Dual-Spindle High-Speed Turning Center para sa High-Tolerance Metalworking

- High precision ball screw

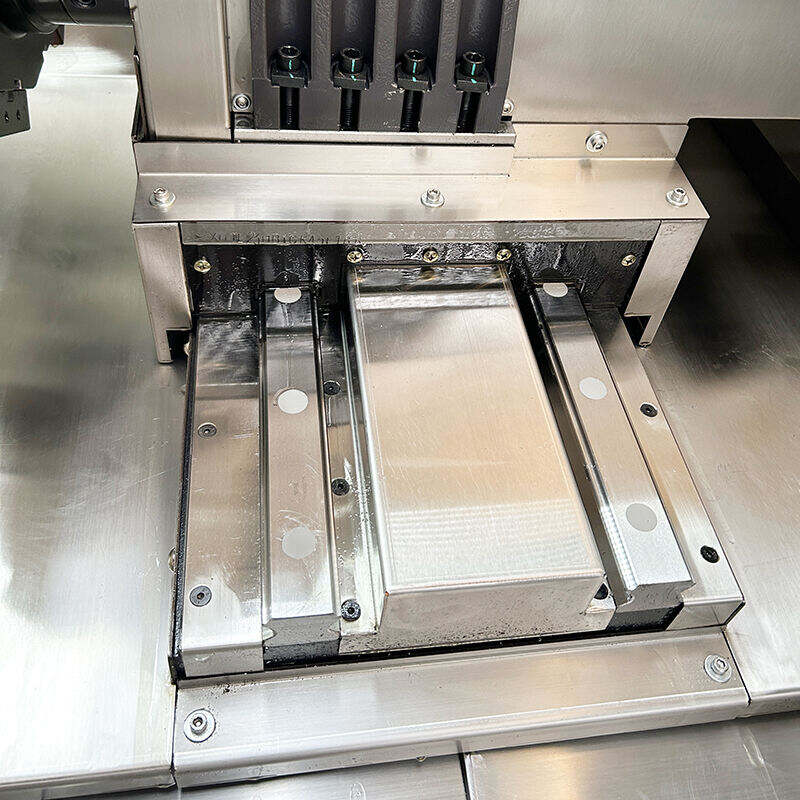

- High precision Roller linear guide

- 12-station powered turret

- Magnetic ring encoder

- Hydraulic programming tailstock

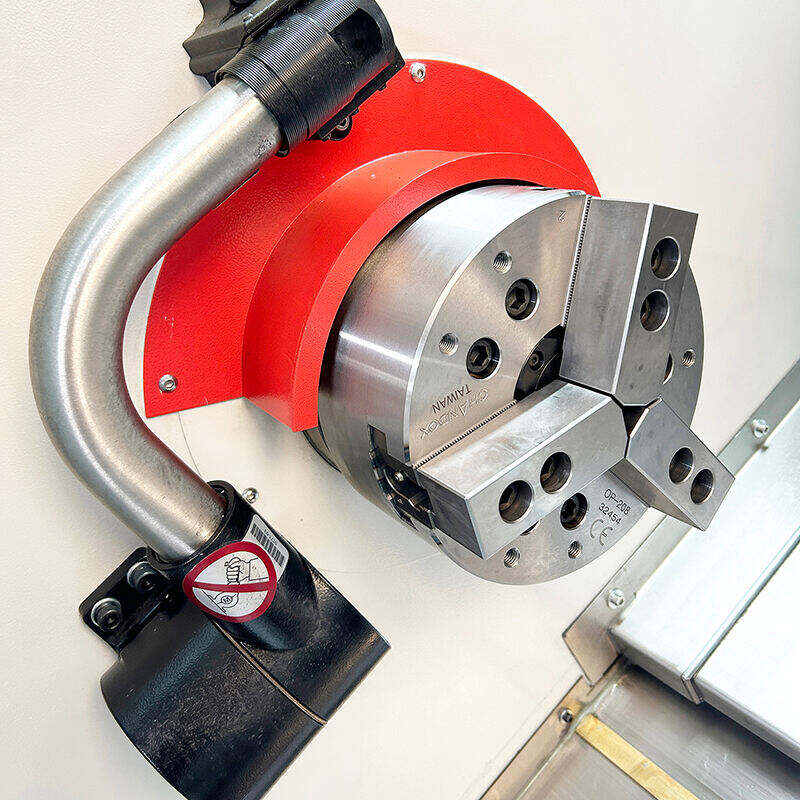

- A2-6 mabigat na tungkulin spindle

- A2-5 Sub-spindle

Panimula

Ang Dual-Spindle High-Speed Turning Center ni DONGS Ang CNC ay inengineered para sa mataas na kahusayan, katumpakan, at versatility sa mga aplikasyon ng metalworking. Ang makabagong makina na ito ay idinisenyo upang pangasiwaan ang mataas na pagpaparaya na mga operasyon at i-optimize ang mga proseso ng produksyon, na ginagawa itong perpekto para sa mga industriya na nangangailangan ng mabilis na mga oras ng turnaround at precision machining. Sa dual-spindle configuration nito, ang turning center na ito ay nag-aalok ng tuluy-tuloy na mga kakayahan sa pagma-machining, na nagbibigay-daan para sa pagtaas ng produktibidad at pinaliit na downtime.

Pinagsasama ng turning center na ito ang pagiging maaasahan ng high-speed performance sa advanced CNC technology para makapaghatid ng mga pambihirang resulta sa paggawa ng mga kumplikadong bahagi na may mahigpit na tolerance. Gumagamit ka man ng iba't ibang metal o naghahanap ng pinakamabilis na turnaround para sa malalaking batch production, tinitiyak ng Dual-Spindle Turning Center ang pinakamataas na kalidad sa bawat operasyon.

Mga Pangunahing katangian:

- Dual-Spindle na Disenyo: Pina-maximize ang throughput sa pamamagitan ng pagpayag sa dalawang tool na gumana nang sabay-sabay, binabawasan ang oras ng pagma-machining at pagtaas ng produktibidad.

- High-Speed Machining: Idinisenyo upang pangasiwaan ang mga high-speed na operasyon, tinitiyak ang katumpakan habang pinapanatili ang mabilis na mga oras ng pag-ikot.

- Advanced na Teknolohiya ng CNC: Nilagyan ng pinakabagong mga kontrol ng CNC para sa pinahusay na katumpakan, madaling pagprograma, at tuluy-tuloy na pagsasama sa mga modernong linya ng produksyon.

- High-Tolerance Precision: Perpekto para sa mga bahagi na nangangailangan ng mahigpit na pagpapaubaya at de-kalidad na pag-finish, na tinitiyak ang pagkakapare-pareho sa bawat pagtakbo ng produksyon.

- Malakas na Konstruksyon: Binuo gamit ang matitibay na materyales upang makatiis sa mga mabibigat na operasyon at matiyak ang pangmatagalang pagganap kahit na sa ilalim ng mapaghamong mga kondisyon.

- Madaling Gamitin na Interface: Pinapasimple ang pagpapatakbo at programming ng makina, binabawasan ang oras ng pagsasanay at pinapataas ang kahusayan ng operator.

- Awtomatikong Tool Changer (ATC): Pinapadali ang mabilis na pagbabago ng tool, pinahuhusay ang kahusayan at versatility ng makina sa iba't ibang operasyon ng machining.

- Pagganap na Matipid sa Enerhiya: Ininhinyero upang bawasan ang pagkonsumo ng enerhiya habang pinapanatili ang mataas na bilis ng operasyon, na ginagawa itong isang cost-effective na pagpipilian para sa pangmatagalang paggamit.

Mga aplikasyon:

- Industriya ng automotive: Tamang-tama para sa paggawa ng mga bahagi na may mataas na katumpakan tulad ng mga bloke ng engine, shaft, at iba pang kritikal na bahagi ng automotive.

- Paggawa ng Aerospace: Perpekto para sa pagmachining ng mga masalimuot na bahagi na nangangailangan ng pambihirang katumpakan at tolerance, kabilang ang mga turbine blades, mga bahagi ng istruktura, at higit pa.

- Mga Bahagi ng Mabibigat na Makinarya: Angkop para sa malakihang machining ng masalimuot, mabibigat na bahagi na ginagamit sa konstruksiyon at pang-industriya na makinarya.

- Industriya ng Langis at Gas: Mahusay na pinangangasiwaan ang produksyon ng mga matibay, mataas na pagganap na bahagi tulad ng mga balbula, tubo, at flanges para sa mga kritikal na aplikasyon.

- Paggawa ng Tooling at Die: Nagbibigay ng high-speed, high-precision turning para sa tooling, molds, at dies sa iba't ibang sektor ng industriya.

- Pangkalahatang Metalworking: Sapat na versatile para sa malawak na hanay ng mga application sa paggawa ng metal, kabilang ang pag-ikot, pagbubutas, at pagtatapos para sa mga metal tulad ng bakal, aluminyo, at titanium.

| Kakayahan | Yunit | TCK52DYS | |

| Distansya sa pagitan ng mga sentro | mm | 900 | |

| Chuck size | tinta | 8/6 | |

| Max. mag-swing sa ibabaw ng kama | mm | 670 | |

| Max. mag-swing sa ibabaw ng cross slide | mm | 400 | |

| Ang lapad ng linear na gabay na riles | mm | 45/45 | |

| PAGPASAYAK | |||

| X-Axis Rapid Traverse (Mabilis na Paglalakbay sa Axis ng X) | m/min | 24 | |

| Z-Axis Rapid Traverse (Ang Mabilis na Paglalakbay sa Z-Axis) | m/min | 24 | |

| Paglalakbay ng X axis | mm | 260 | |

| Z axis na paglalakbay | mm | 800 | |

| Y axis travel | mm | ±50 | |

| PANGUNING SINILAN | PANGUNAHING A2-6 | Sub A2-5 | |

| Max. spindle speed | rpm | 4200 | 5000 |

| Max. Pwersa ng Spindle | kW | 22 | 15 |

| Spindle nose | - | PANGUNAHING A2-6 | Sub A2-5 |

| kapasidad ng bar | mm | 52 | 46 |

| TURRET | |||

| Numero ng tool station | - | 12 | |

| Uri ng torret | - | BMT55 | |

| Mga tool na nag-rotary | r/min | 5000/4000 | |

| tAILSTOCK | |||

| diameter ng bulate | mm | / | |

| paglalakbay sa bulate | mm | / | |

| paglalakbay ng tailstock | mm | sub spindle 650 | |

| tailstock taper | - | MT5 | |

| Sukat | |||

| Sukat ng packing | m | 3.7 | |

| Lapad | m | 2 | |

| Taas | m | 2.5 | |

| Net Weight | kg | 5 |

Faq

Q:Sino kami?

A: Kami ay isang tagapagtatag ng pag-unlad sa larangan ng kagamitan na CNC. Kami ay isang manunuo na tumutok sa paggawa ng mga turning center na mataas ang produktibidad, CNC slant-bed lathes, CNC flat lathes, machining centers, at vertical lathes na katamtaman at malalaki. Seryosamente inuulit namin ang pagsangguni sa mga estratetikong partner sa buong mundo upang ipag-uusad ang mga trend sa industriya.

Q: Paano ko mapipili ang pinakamahusay na makina?

A: Pakisabi sa amin ang iyong mga espesipikasyon at maaari naming pumili ng pinakamainam na modelo para sa iyo, o pumili ka ng eksaktong modelo.

Q: May aktwal na fabrica ba kayo?

A: Oo, kami ay isang manununo ng CNC lathe sa Lungsod ng Tengzhou, Lalawigan ng Shandong. Mayroon kaming isang propesyonal na pangkat ng teknikal, pang-venta, at pagkatapos-mga serbisyo.

Q: Anong mga serbisyo ang maaaring aming ibigay?

A: Tinatanggap na termino ng paghahatid: FOB, CFR, CIF, EXW; Tinatanggap na mga salapi para sa pagbabayad: USD, RMB; Tinatanggap na uri ng pagbabayad: T/T, L/C, Western Union; Ginagamit na mga wika: Ingles, Tsino

Q: Paano namin siguraduhin ang kalidad?

A: Gaganapin ang mga sample bago ang pagsasabuhay ng masang produksyon; isasagawa ang huling inspeksyon bago ang pagpapadala;

Q: Bakit dapat bumili sa amin habang may iba pang mga tagatulong?

A: Specialize kami sa paggawa ng mga produkto na ito sa loob ng 20 taon at nakamit na ang sertipikasyong ISO 9001, sertipikasyong CE at sertipikasyong EAC.

Q: Pwede ba mong ipersonal ang makina?

A: Oo, nag-integrate kami ng disenyo at pag-unlad, may karanasang mga inhinyero at tekniko sa paghahanda.

Q: Pwede ba akong bisitahin ang inyong fabrica?

A: Sige, sobrang tinanggap ka namin.