6S Management for Operational Excellence

6Dongshi CNC's implementation of the 6S management system has been instrumental in achieving operational excellence. The 6S methodology, which stands for Sort, Set in Order, Shine, Standardize, Sustain, and Safety, is a powerful tool for improving workplace organization, cleanliness, and safety.

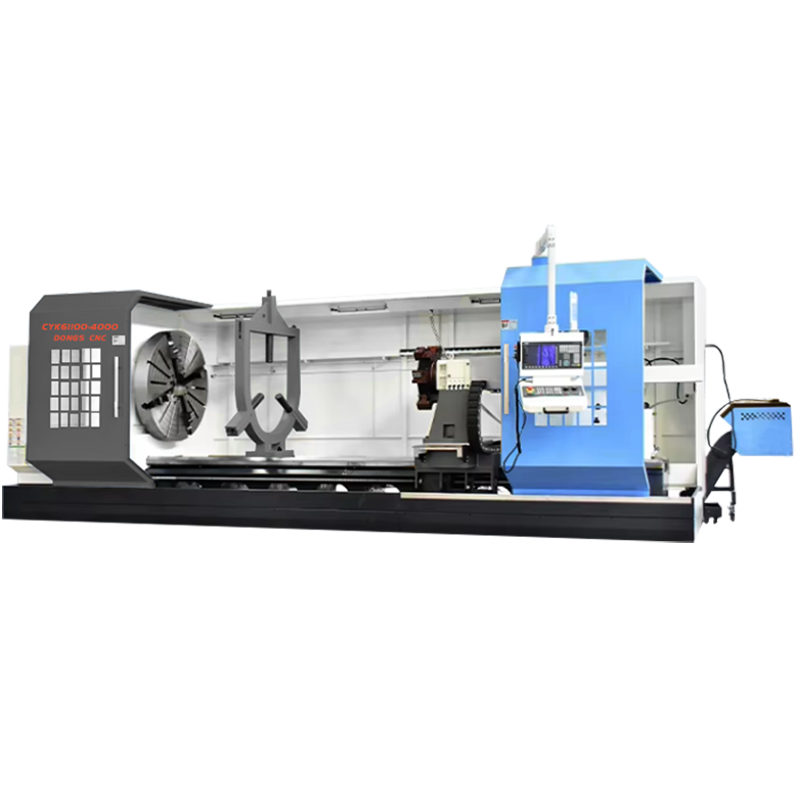

By adopting 6S, Dongshi CNC has transformed its production facilities into highly efficient and well-organized environments. The company's employees are trained to maintain a high level of discipline and attention to detail, ensuring that every aspect of the production process is optimized.

One tangible result of 6S implementation is the reduction in downtime and waste. By minimizing clutter and ensuring that tools and materials are always in their designated places, Dongshi CNC has significantly improved production efficiency and reduced the risk of errors. This, in turn, has led to cost savings and improved customer satisfaction.

Moreover, the emphasis on safety in the 6S methodology has helped Dongshi CNC create a safe and healthy work environment for its employees. The company's commitment to safety has earned it numerous accolades and has further solidified its reputation as a responsible and reliable business partner.