nc machine

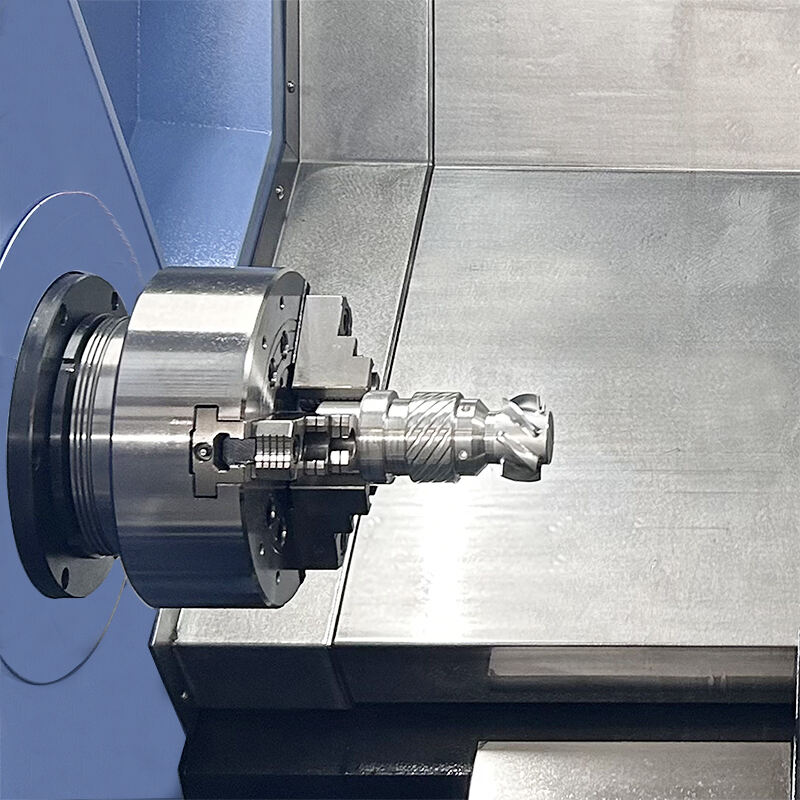

- High precision Roller linear guide

- High precision ball screw

- lmported precision bearing

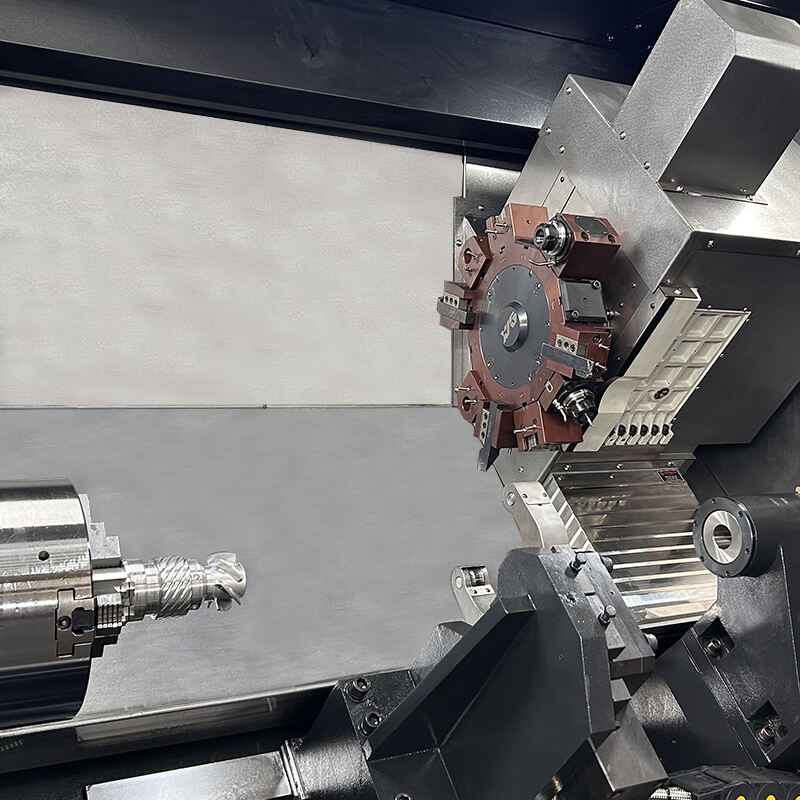

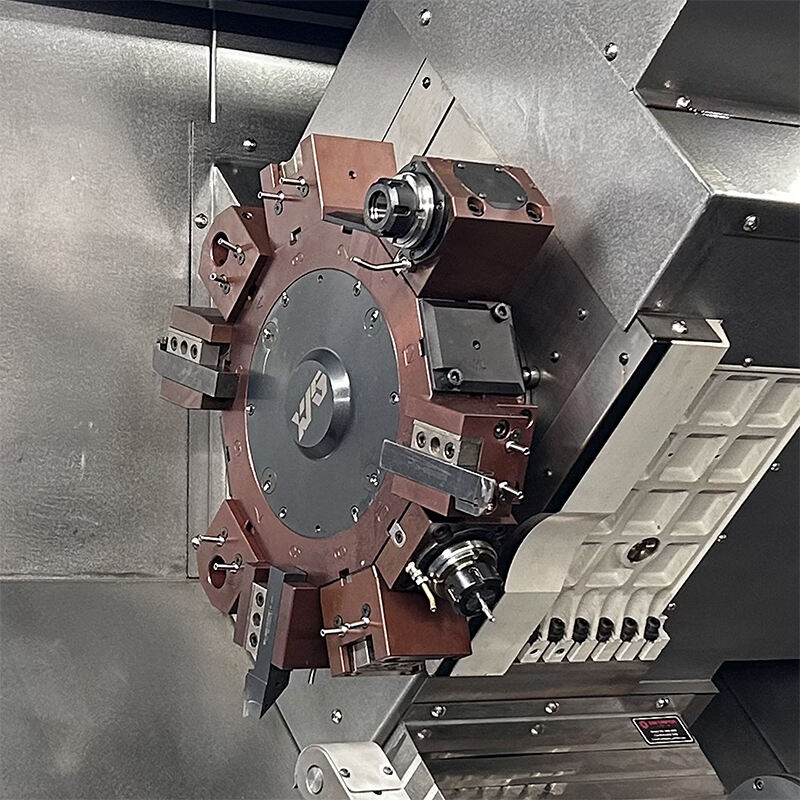

- Servo hydraulic turret

- 12 Station live tooling

- Tool setting instrument is optional

Introduction

1、Main features of nc machine:

The TCK600DY nc machine series of high-rigidity horizontal processing equipment focuses on the precision and efficient manufacturing needs of large and complex components in multiple fields. It adopts a technical solution that combines a reinforced bed structure with an intelligent CNC system, and shows significant advantages in dealing with high-precision processing of large-size workpieces. The equipment has particularly enhanced its adaptability to heavy cutting conditions to meet industrial scenarios with strict requirements on equipment stability and processing efficiency. Through modular functional configuration, it can meet both customized small-batch precision processing and large-scale continuous production rhythm. It is particularly good at handling heavy-duty processing tasks with strict tolerance requirements, such as large structural parts in the aerospace field, key load-bearing components of energy equipment, and complex transmission systems in the rail transit industry.

2、nc machine main application areas

Heavy Machinery Manufacturing: Ideal for machining large components such as gears, shafts and housings used in heavy machinery production.

Automotive Industry: Ideal for the production of automotive parts such as engine blocks, crankshafts and large transmission components.

Aerospace and Defense: High-precision manufacturing of critical aerospace components such as turbine blades, aircraft frames and large engine components.

Oil and Gas: Suitable for machining large components for the oil and gas industry, including valves, pumps and pressure vessels.

Energy Industry: Machining energy production parts, including turbine rotors, generator components and other heavy machinery.

General Manufacturing: Suitable for industries that require high-precision and high-efficiency machining of large and heavy parts, including industrial pumps and equipment.

Shipbuilding: Used to produce large components for the shipbuilding industry, such as propellers, rudders and other structural parts.

| Technical specifications | unit | TCK600DY | ||

| Processing range | Maximum rotation diameter on the bed | mm | Φ630 | |

| Maximum rotation diameter on the saddle | mm | Φ450 | ||

| Maximum machining diameter | mm | Φ600 | ||

| Center distance | mm | 1100/1600 | ||

| Spindle | Spindle head type | mm | A2-8 | |

| Spindle through hole diameter | mm | 86 | 105 | |

| Bar diameter < | mm | 74 | 91 | |

| Maximum spindle speed | r/min | 3000 | 2500 | |

| Main motor rated output | Kw | 15KW | ||

| Fixture | Hydraulic chuck | inch | 10/12 | |

| Tailstock | Tailstock sleeve | mm | MT5 | |

| Tailstock movement form | / | Hydraulic automatic | ||

| Tailstock travel | mm | 1100/1600 | ||

| Tailstock guide form | / | Hard rail | ||

| Saddle | Tilt angle | DEG | 45 ° | |

| Move distance X/Z | mm | 310 1100/1600 | ||

| Move distance Z | mm | 1100/1600 | ||

| Y axis travel | mm | ±50 quad rail | ||

| Fast moving speed X/Z | m/min | 24/24 | ||

| Servo motor X/Z | KW | 2.9/2.9 | ||

| turret | Tool holder type | - | 12-station power turret | |

| Adjacent tool change time | S | 0.5 | ||

| Number of tool positions | / | 12-station BMT55 | ||

| Tool size (turning/boring) | mm | 25×25 Φ40 | ||

| Spring chuck model | / | ER32 | ||

| Power turret power | KW | 2.2 | ||

| Power turret speed | rpm | 3000-5000 | ||

| Servo motor Y | KW | 2.2 | ||

| Center distance | Dimensions | Weight (approx.) | ||

| 1000 | 4200X2100X2300mm | 6200KG | ||

| 1500 | 4700X2100X2300mm | 7200KG | ||

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001

certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.