cnc mill

- High quality resin sand cast iron

- Taiwan main axis

- Taiwan ball screw and lock nut

- Taiwan booster cylinder

- NSK bearing in Japan

- German R + W coupling

- Automatic lubrication system

- Selection of chip conveyor

Introduction

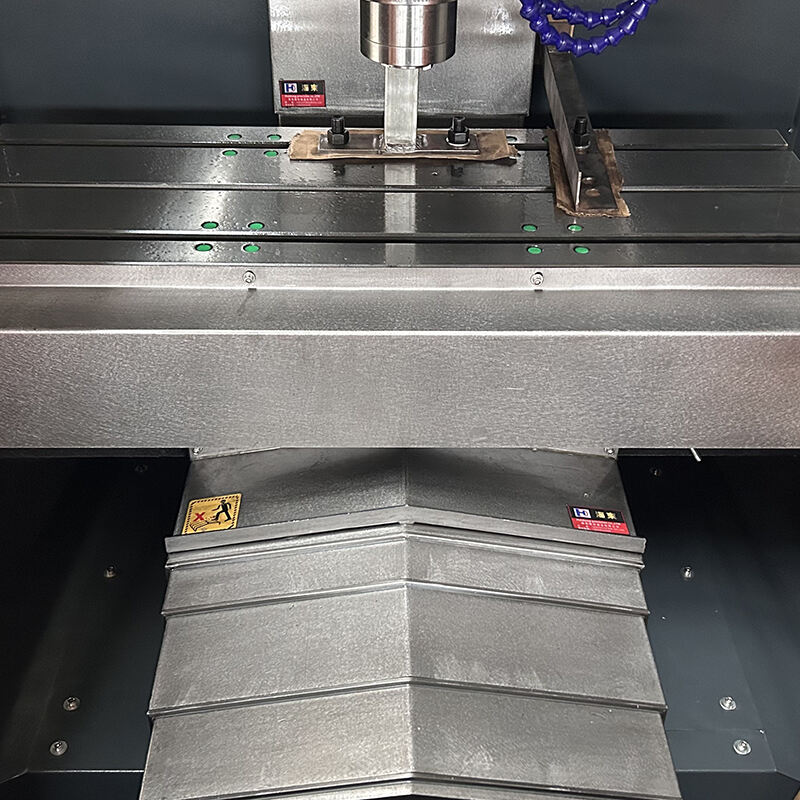

1. The three axes use linear slide rails, which have high rigidity, high positioning accuracy, low noise, and low friction characteristics. They can be quickly displaced and obtain the best circular precision;

2. The main structural castings are made of high-quality Meehanite cast iron, which has a stable structure and permanently ensures quality;

3. The castings are calculated and analyzed by computer using the finite element analysis method, and the reasonable structural strength and reinforcement ribs are matched to provide high rigidity of the machine;

4. The ultra-wide base and columns are both box-type structures, the saddle is widened and lengthened, and the heavy-load full support design is solid in structure to ensure heavy-load capacity during processing;

5. The spindle head is reinforced with ribs , the contact length ratio between the spindle head and the column is appropriate, providing a stable support for the spindle;

6. The machine is equipped with an anti-collision device, which can absorb the vibration caused by the collision caused by the worker's operating error, minimize the damage caused by the collision, and ensure the original accuracy;

7. The machine adopts an oil-water separation design, which can effectively separate the lubricating oil and the cutting fluid to prevent the cutting fluid from deteriorating due to mixing and affecting the processing quality;

8. The machine adopts Taiwan's high-precision, high-rigidity, and high-precision spindles. The belt-type spindles are strong in rigidity and high in reliability. The direct-drive spindles are high-speed, high-efficiency, high-precision, low-noise, and low-vibration, fully meeting user needs;

| Specifications | Unit | VMC650 | VMC640 | VMC550 |

| Table size | mm | 900×410 | 1000x360 | 800×260 |

| Table maximum load | kg | 400 | 300 | 200 |

| X/Y/Z axis travel | mm | 650x450x500 | 650x400x500 | 550x320x450 |

| Distance between spindle centerand column guide surface | mm | 500 | 440 | 350 |

| Distance between spindle end face and worktable surface | mm | 100-600 | 100-600 | 80-530 |

| X/Y/Z Max. Rapid traverse | m/min | 24/24/24 | 24/24/24 | 24/24/24 |

| Maximum spindle speed | r/min | 8000 | 8000 | 8000 |

| Spindle taper hole | - | BT40/120 | BT40/120 | BT40/120 |

| Spindle motor | kw | 5.5-7.5 | 5.5-7.5 | 3.7-7.5 |

| X / Z torque motor | n.m | 10/10/15 | 7/7/15 | 6/6/15 |

| Screw diameter | mm | Φ32/12 | Φ32/12 | Φ28/12 |

| Repeat positioning accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Guide rail form | mm | Track | Track | Track |

| Magazine capacity | t | 16/16 | 16/12 | 12 |

| Tool magazine form | - | Robot/Bonnet | Robot/Bonnet | Robot/Bonnet |

| Machine size (L x W x H) | m | 2.5×2.2×2.5 | 2.5×2.2×2.5 | 2.2×2×2.3 |

| Machine weight (approx.) | t | 4 | 3.5 | 3 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.