CNC vertical lathe

- Taiwan High precision wire rail, lead screw

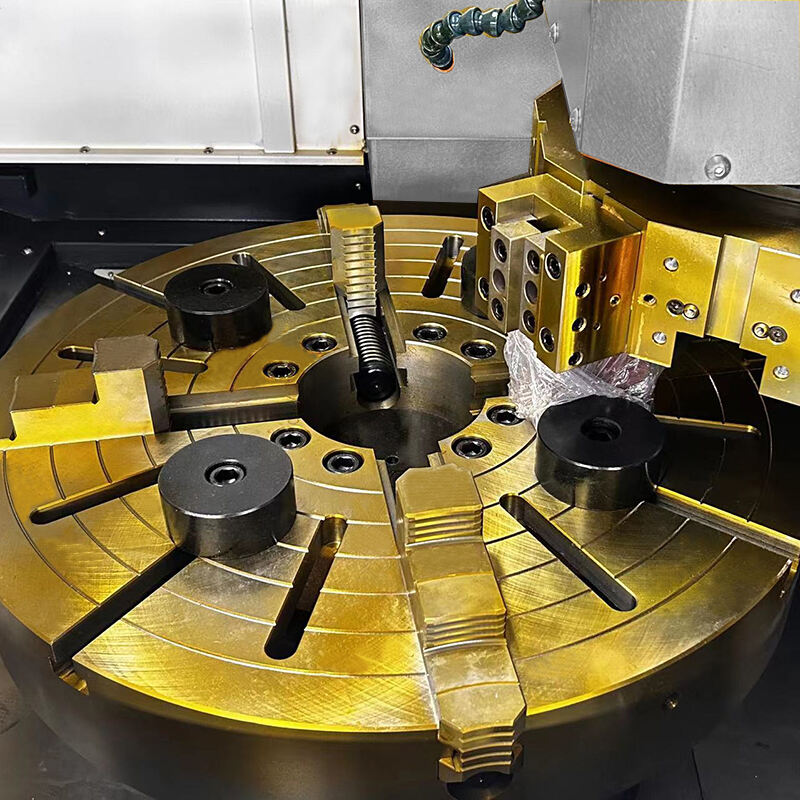

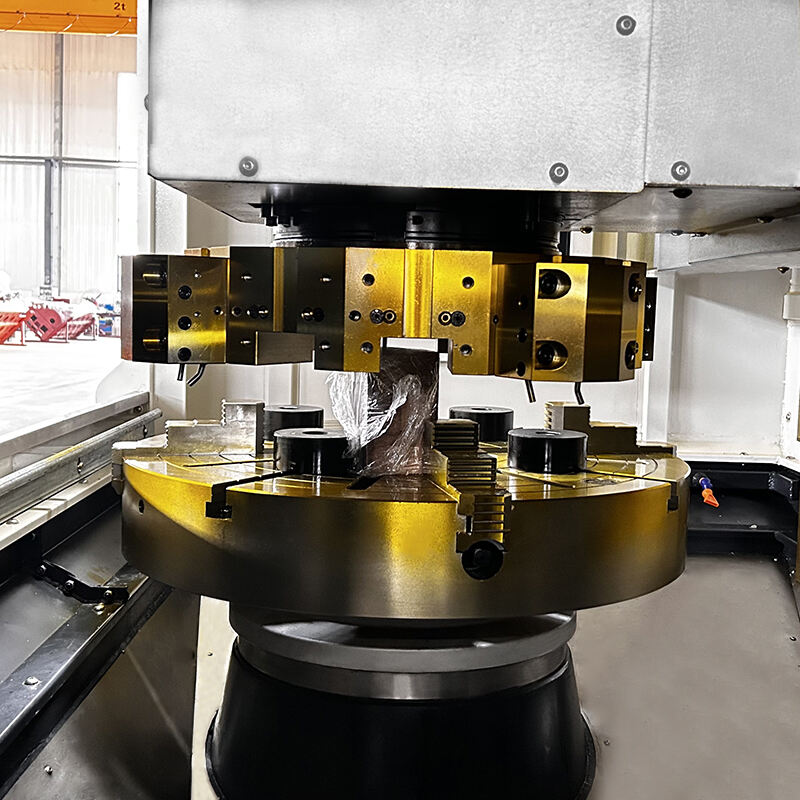

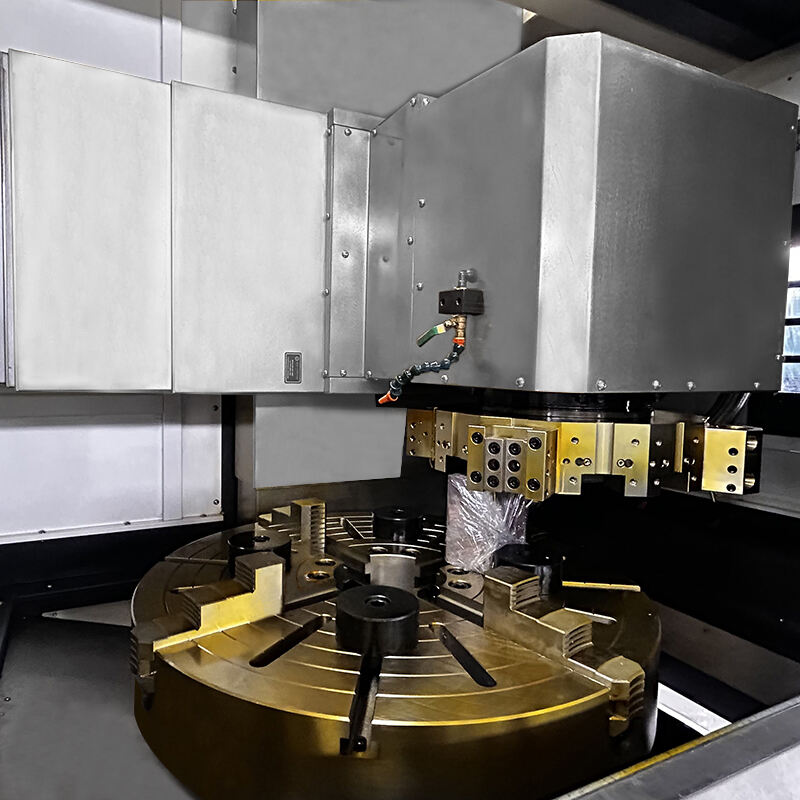

- Taiwan hydraulic chuck

- Taiwan brand spindle

- Taiwan brand turret

- Volumetric lubrication

- Chain chip conveyor

- Three-color alarm light, foot switch, electric cabinet air conditioner

- Inner protection of lead screw wire rail

- Fully protective sheet metal cover, pneumatic sliding door

- Matching hydraulic station

- The spindle can add C axis and equipped with power turret

Introduction

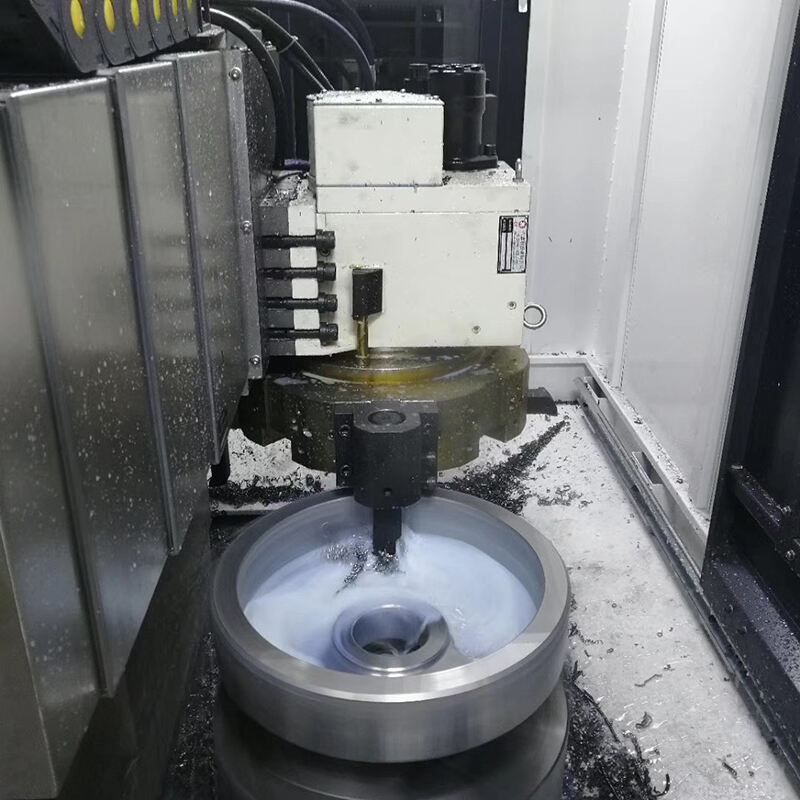

1.This machine tool is a wall plate structure. The columns, base and slide are all made of high-grade gray cast iron resin sand casting technology and are aging treated. The guide surface adopts 55 roller linear guides, which have large bearing capacity and good precision stability. Reasonable structural design, perfect processing and assembly technology ensure the stability and precision retention of the machine tool for long-term use.

2. The machine tool spindle adopts a wide-range large-torque servo motor drive, which can not only have low-speed and high-torque, strong and heavy cutting, but also high-speed cutting. It can meet the needs of roughing and finishing at the same time.

3. The machine tool spindle adopts high-precision double-row cylindrical roller bearings and bidirectional thrust angular contact ball bearings and double-row cylindrical roller bearings. This configuration structure has the largest bearing capacity, can withstand large cutting force and feed force, has high radial stiffness and axial stiffness, and high rotation accuracy.

4. The X and Z axis servo motors directly drive the precision ball screw pair through a flexible coupling, which can minimize the reverse clearance and have high positioning accuracy. The Z axis lifting is equipped with a nitrogen balance system, which has a simple and reliable structure and fast speed.

The X and Z axes use domestic precision ball screw pairs and special bearings for ball screws to meet the requirements of high rigidity and high precision cutting. The screw support adopts a pre-stretched structure, which greatly reduces the influence of thermal deformation on the accuracy of the machine tool during long-term operation.

5. The X and Z axes use advanced centralized automatic lubrication devices, which are automatically lubricated at regular intervals, and work stably and reliably.

6. The machine tool turret is equipped with an eight-station hydraulic turret as standard, and electric turret or row tool form can be selected.

Main application areas:

Energy equipment manufacturing: Wind power industry: Processing large parts such as the main shaft, hub, gearbox housing, etc. of wind turbines.

Heavy machinery manufacturing: Mining machinery: Processing large gears, bearing seats, crusher rotors, etc.

Aerospace and military industry: Aircraft engines: Processing high-temperature alloy parts such as turbine discs and combustion chamber housings.

General machinery and molds: Valves/pump bodies: Processing large-caliber valve housings, pump body end covers, etc.

Transportation: Rail transportation: High-speed rail wheel hubs, brake discs, etc.

| Specifications | Unit | VTC850 | VTC1000 |

| Maximum rotation diameter of workpiece | mm | 900 | 1000 |

| Maximum machining diameter | mm | 850Plate 700cylinder | 900 |

| Hydraulic chuck diameter | mm | 630 | 800 |

| Spindle speed | rpm | 50-800/ 1:2.5(gear ratio) | 50-800 |

| Spindle model | - | A2-11 | A2-11 |

| Spindle output torque | NM | 875 | 1050 |

| Vertical movement distance of tool carrier | mm | 750 | 700 |

| Horizontal moving distance of tool rest | mm | -50-550 | -50-550 |

| Track width | mm | 55pin roller | 55Heavy duty roller |

| X/Z-axis fast moving speed | m/min | 15/12 | 15/12 |

| Turret form | - | 8Station servo turret/four-station/cutter arrangement | |

| Cutter bar section | mm | 32×32 | 32×32Boring tool holder 40/50 |

| Main motor power | kw | 22-30(Low frequency high torsion) | 22-30(Low frequency high torsion) |

| XPower and torque of feed motor | kw/nm | 2.4 /15 | 2.8/18 |

| ZPower and torque of feed motor | kw/nm | 2.8/18 | 2.8/18 |

| Diameter of X / Z axis ball screw | mm | 4010/5010 | 5010/5010 |

| Repeated positioning accuracy of machine tool | mm | ±0.005 | ±0.005 |

| The weight of the machine tool is about | T | 8.8 | 10.8 |

| Outline dimension of machine tool | m | 2.8×2.0×3.2 | 2.9×2.9×3.5 |

| Specifications | Unit | VTC1250 | VTC1400 | VTC1600 |

| Maximum rotation diameter of workpiece | mm | 1250 | 1400 | 1600 |

| Maximum machining diameter | mm | 1050 | 1250 | 1400 |

| Spindle speed | rpm | 20-500Double speed gear box | 20-400Double speed gear box | 20-350Double speed gear box |

| Vertical movement distance of tool carrier | mm | 800 | 800 | 800 |

| Horizontal moving distance of tool rest | mm | -50-650 | -50-750 | -50-850 |

| X-axis fast moving speed | m/min | 15 | 15 | 15 |

| Z-axis fast moving speed | m/min | 12 | 12 | 12 |

| Turret form | - | Vertical 4 station | Vertical 4 station | Vertical 4 station |

| Cutter bar section | mm | Φ32/50 | Φ32/50 | Φ32/50 |

| Main motor power | kw | 22/30 | 22/30 | 30/37 |

| Hydraulic chuck diameter | mm | Manual four-jaw chuck1000 | Manual four-jaw chuck1250 | Manual four-jaw chuck1400 |

| X/Z Power and torque of feed motor | kw/nm | 3.5/22 | 3.5/22 4.7/30 | 4.7/30 |

| X/Z Linear guide rail | mm | 65/55pin roller | 65/55pin roller | 65pin roller |

| X/Z lead screw diameter | mm | Φ50 | Φ50 | Φ63 |

| The weight of the machine tool is about | t | 12.8 | 13.8 | 15.5 |

| Outline dimension of machine tool | m | 2.7×2.85×3.25 | 2.8×2.95×3.25 | 3.0×3.0×3.25 |

FQA

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.