cnc turning

- High precision ball screw

- High precision Roller linear guide

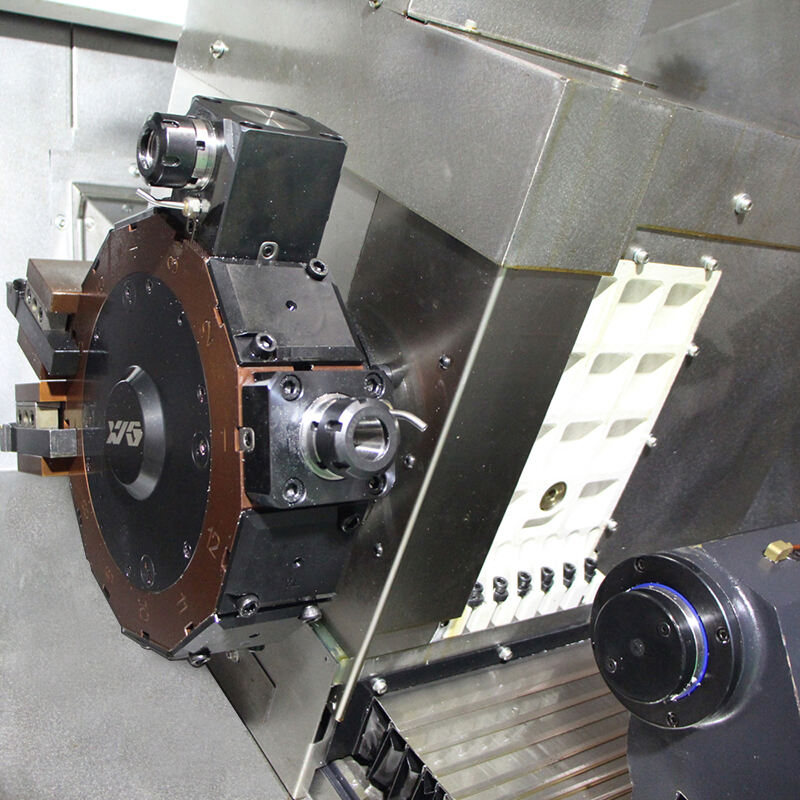

- 12-station powered turret

- Magnetic ring encoder

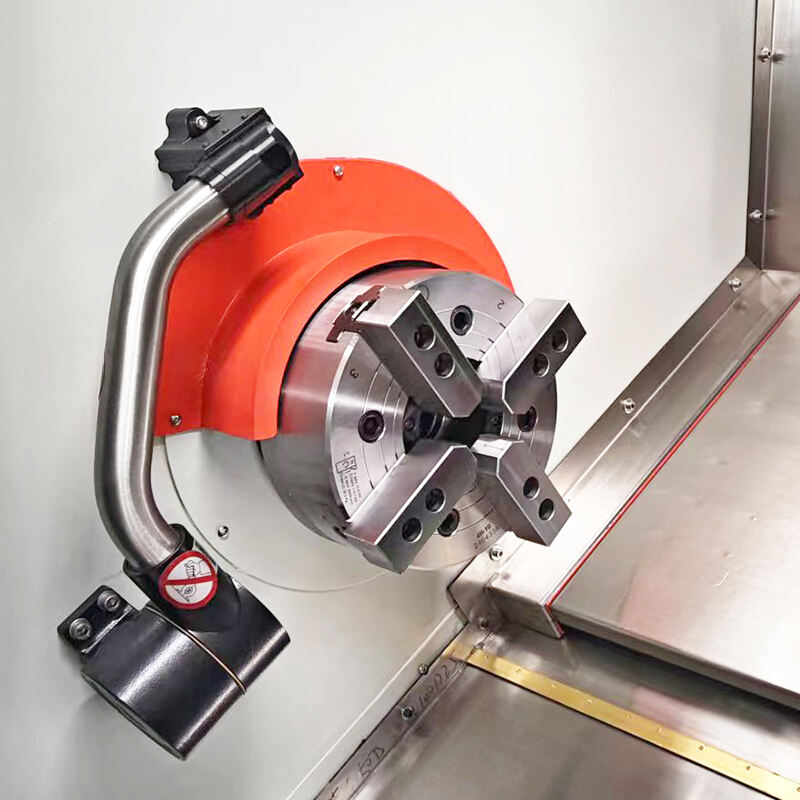

- Hydraulic programming tailstock

- A2-6/A2-8 heavy duty spindle

Introduction

The main features of CNC turning

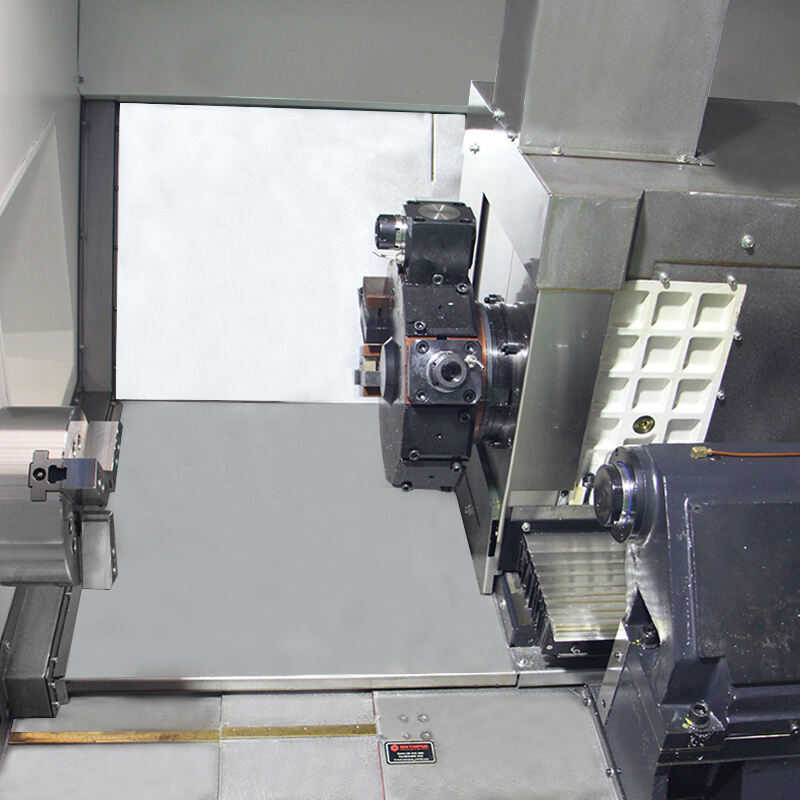

1. Bed

This machine adopts an integrated inclined bed structure with an inclination angle of 30 degrees. It is made of HT300 high-strength cast iron through resin sand mold casting process. Through the optimized grid-shaped reinforcement rib layout and the imported precision rolling guide system from Germany, low-friction and high-rigidity operation characteristics are achieved. This structure has excellent vibration resistance and deformation suppression capabilities, effectively guarantees the stability of processing accuracy, and supports high-speed displacement function, significantly improving the comprehensive processing efficiency of the equipment.

2. Two-axis feed

The Z-axis movement mechanism is completed by the saddle assembly along the bed guide rail, and the X-axis movement is achieved by the slide assembly driving the tool system. The dual-axis power transmission adopts the Japanese THK precision ball screw pair, which is directly connected to the Yaskawa servo motor through an elastic coupling. This transmission scheme has micron-level positioning accuracy, effectively eliminates reverse clearance, and ensures that the trajectory reproducibility reaches the ±0.003mm standard.

3. Saddle and skateboard

The saddle components are manufactured using an integral casting process, and the material is HT300 cast iron consistent with the bed to ensure thermal stability matching. The slide unit is equipped with a Swiss Schneider roller guide system. Its X-axis drive integrates a high-precision preloaded screw mechanism. The power transmission link uses a zero-backlash coupling device, which is combined with a fully closed-loop feedback system to achieve precise control of the tool path. The specially designed wedge adjustment mechanism can compensate for the mechanical clearance caused by long-term use and maintain the long-term accuracy of the equipment.

The main areas of CNC turning:

Automotive Parts Manufacturing: Suitable for the production of high-precision automotive parts such as shafts, hubs, gears, engine blocks, etc.

Aerospace Industry: Ideal for the manufacture of critical aerospace components that require tight tolerances and high-quality surface finishes.

Heavy Machinery Manufacturing: Suitable for machining large components used in construction equipment and industrial machinery.

Oil and Gas Industry: Used to produce parts such as valves, fittings and drilling equipment for the oil and gas industry.

General Metalworking: Provides solutions for turning operations in general manufacturing, such as the production of machine parts, tools and other precision components.

Tool and Die Manufacturing: Ideal for machining tools and dies for the production of molded parts.

Energy Sector: Vital for the production of parts used in power generation and renewable energy equipment.

| Technical specifications | unit | TCK52DY | |

| Processing range | Maximum rotation diameter on the bed | mm | Φ650 |

| Maximum rotation diameter on the saddle | mm | Φ400 | |

| Maximum machining diameter | mm | Φ470 | |

| Center distance | mm | 600/800/1000 | |

| Spindle | Spindle head type | mm | A2-6 |

| Spindle through hole diameter | mm | 66/79 | |

| Bar diameter < | mm | 50/65 | |

| Maximum spindle speed | r/min | 4200 | |

| Main motor rated output | Kw | 11-15 | |

| Fixture | Hydraulic chuck | inch | 8/10 |

| Tailstock | Tailstock sleeve | / | MT5 |

| Tailstock movement form | / | Slide drive | |

| Sleeve diameter | mm | 80 | |

| Tailstock travel | mm | 490/740/990 | |

| Tailstock guide form | / | Hard rail | |

| Saddle | Tilt angle | DEG | 30 |

| Move distance X | mm | 260 | |

| Move distance Z | mm | 610/830/1070 | |

| Y axis limit travel | mm | ±50 quad rail | |

| Fast moving speed X/Z | m/min | 24/24 | |

| Servo motor X/Z/Y | KW | 2.5/2.5/1.4 | |

| turret | Turret diameter | mm | Cutter diameter 380 |

| Time between tool changes | S | 0.5 | |

| Number of tool positions | / | 12 station | |

| Turret type | Servo Hydraulics | BMT55-12 station power | |

| Power shaft power | KW | 2.7 | |

| Power shaft speed | rpm | 4000 | |

| Spring chuck model | / | ER32 | |

| Tool size | mm | 25×25 | |

| Center distance | Dimensions | Weight (approx.) | |

| 600 | 3350X2000X2300mm | 4000KG | |

| 800 | 3600X2000X2300mm | 4300KG | |

| 1000 | 3600X2000X2300mm | 4700kg | |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.