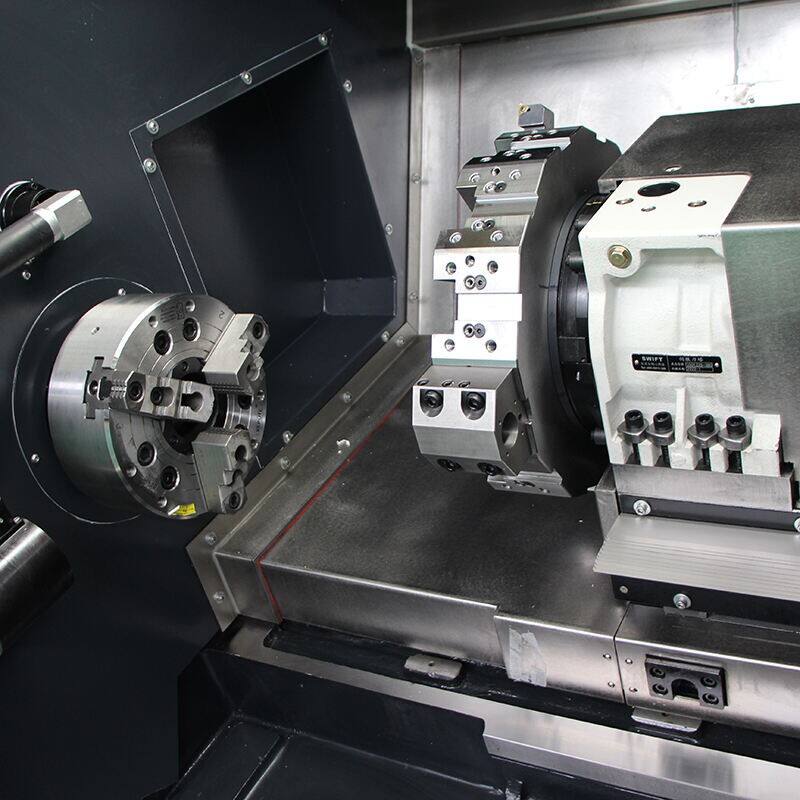

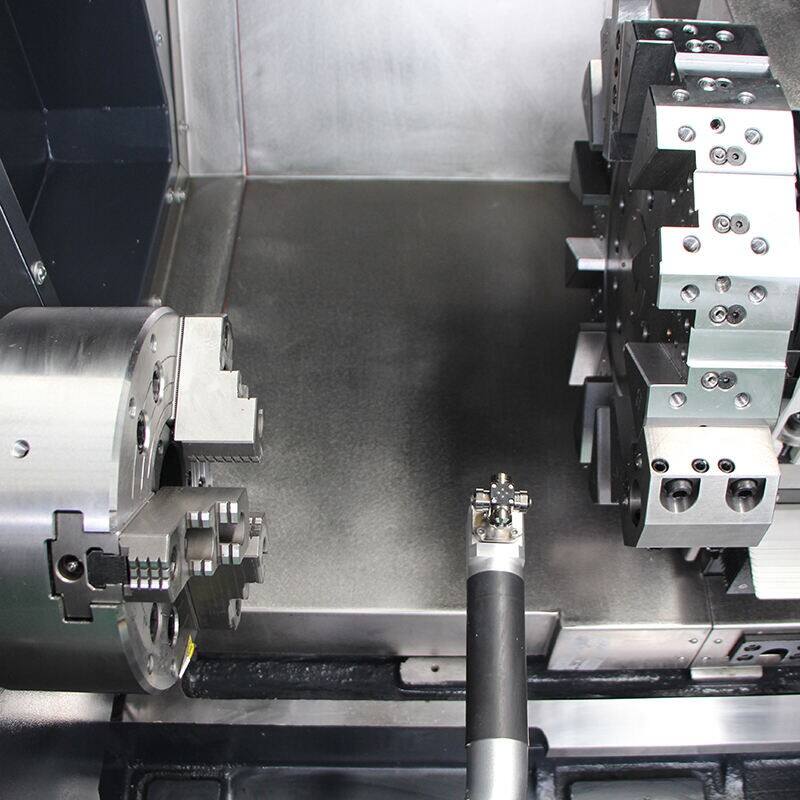

Compact Slant Bed CNC Lathe – Space-Saving Design with High Accuracy

- High precision Roller linear guide

- High precision ball screw

- Imported precision bearing

- Optional combined power milling head

- Optional multi station turret

- Optional 12 Station live tooling y-axis

- Main shaft synchronous belt drive

Introduction

The Compact Slant Bed CNC Lathe from DONGS CNC is a precision-engineered solution designed for manufacturers seeking high accuracy in a space-efficient design. This lathe is tailored for businesses with limited floor space but still requires robust performance for intricate machining tasks. Featuring advanced CNC controls and a stable slant bed construction, it ensures consistent precision and efficiency in every operation. Ideal for small to medium-sized components, this lathe is perfect for industries demanding high-quality production standards.

Key Features:

- Space-Saving Design: Compact footprint to optimize workshop space without sacrificing functionality.

- High-Precision CNC Control System: Delivers precise results with intuitive and user-friendly programming.

- Rigid Slant Bed Structure: Enhances stability and reduces vibration for superior machining accuracy.

- Energy-Efficient Spindle Motor: Provides reliable power while minimizing energy consumption.

- Ergonomic Layout: Facilitates easy operator access and smooth workflows.

- Efficient Cooling System: Prevents overheating during prolonged operations for consistent performance.

- Versatile Machining Capabilities: Supports turning, threading, and other essential operations.

- Durable Construction: Designed with high-quality materials for long-term reliability and low maintenance.

Applications:

- Precision Engineering: Ideal for producing small, high-accuracy components for machinery and devices.

- Medical Equipment Manufacturing: Machining intricate parts for medical tools and instruments.

- Electronics Industry: Creating housings and precision parts for electronic devices.

- Automotive Components: Fabricating small yet critical car parts such as fittings and fasteners.

- Jewelry and Craftwork: Manufacturing detailed designs and decorative items.

- Educational Institutions: Perfect for training programs in machining and CNC operations.

| CAPACITY | Unit | TCK50L |

| Distance between centers | mm | 500 |

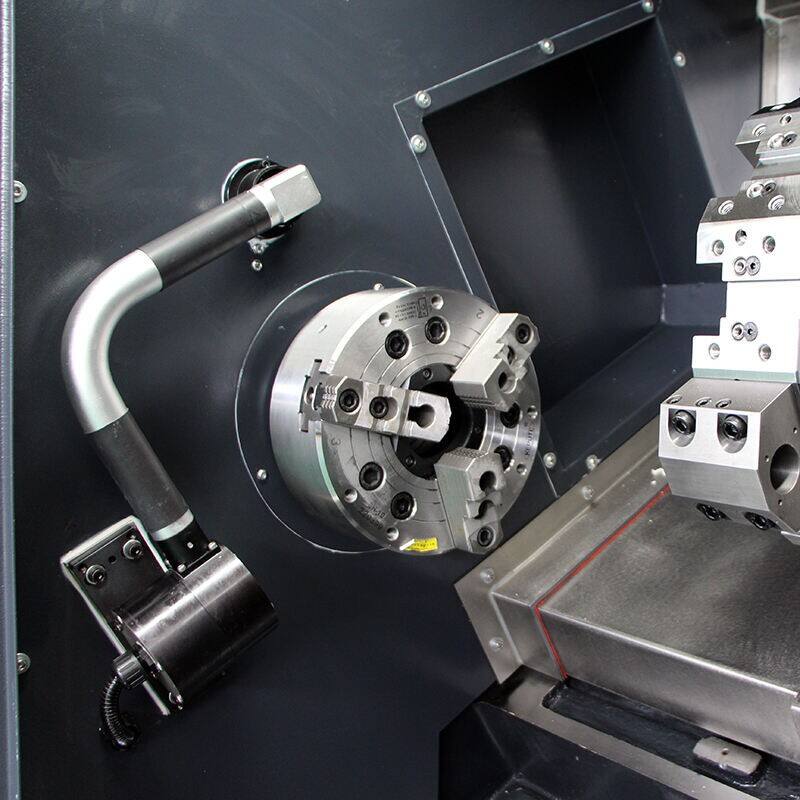

| Chuck size | inck | 8 |

| Max. swing over bed | mm | 520 |

| Max. swing over cross slide | mm | 260 |

| Linear guide rail width | mm | 35/35 |

| TRAVELS | ||

| X-Axis Rapid Traverse | m/min | 20 |

| Z-Axis Rapid Traverse | m/min | 20 |

| X axis travel | mm | 240 |

| Z axis travel | mm | 470 |

| MAIN SPINDLE | ||

| Max. Spindle Speed | rpm | 4200 |

| Max. Spindle Power | kw | 11 |

| Spindle nose | - | A2-6 |

| bar capacity | mm | 52 |

| TURRET | ||

| No. of tool station | - | 8 |

| Turret Type | - | BMT45 |

| tailstock | ||

| quill diameter | mm | Hydraulic programmable movement |

| quill travel | mm | |

| tailstock Travel | mm | 400 |

| tailstock taper | - | MT4 |

| DIMENSIONS | ||

| Packing size | m | 2.75 |

| Width | m | 1.9 |

| Height | m | 2.2 |

| NET Weight | kg | 3300 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.