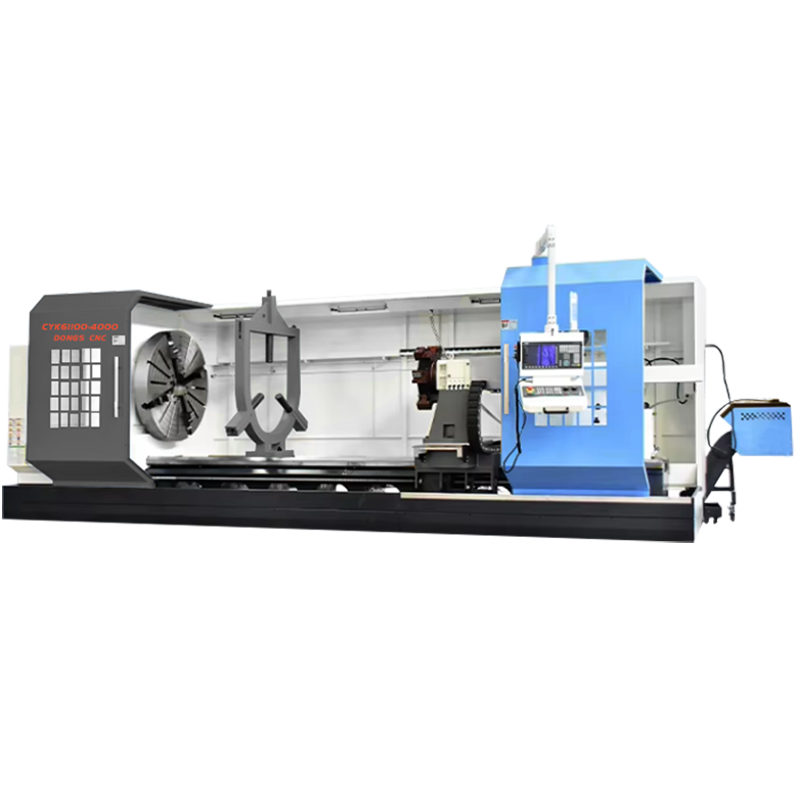

Customizable Flat Bed CNC Lathe for High-Volume Production

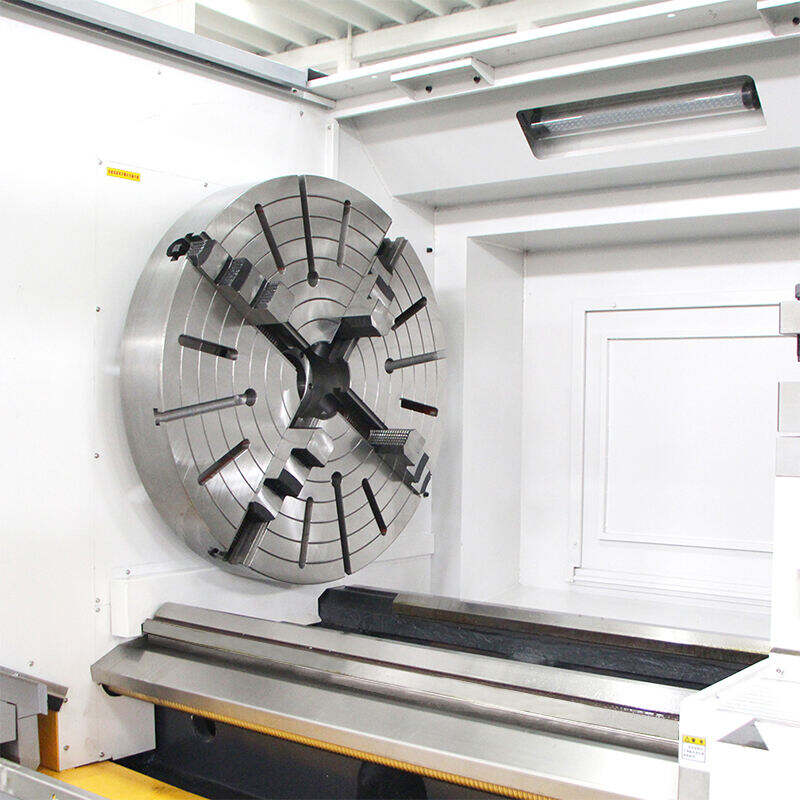

- Widening of guide railIntegral casting bed

- The headstock is widened and lengthened

- Precision grinding screw

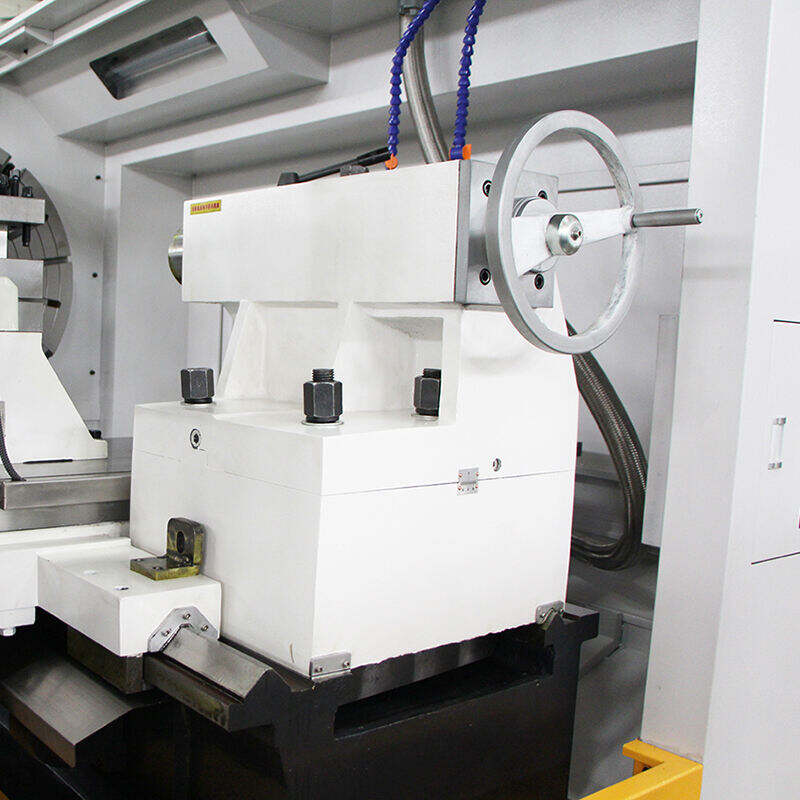

- Widened carriage

- Automatic centralized lubrication

Introduction

| Specifications | Unit | CK6165 | CK6180 | CK61100 | CK61125 |

| swing over bed | mm | ф660 | ф800 | ф1000/1100 | ф1250 |

| swing over cross slide | mm | ф380 | ф480 | ф600 | ф850 |

| Max processing length | mm | 1000-3000 | 1500-3000 | 1500-12000 | 1500-12000 |

| X axis travel | mm | X:315 | X:470 | X:560 | X:650 |

| Rail width | mm | 440 | 600 | 700 | 755 |

| Spindle speed | rpm | 20-1400 | 25-800 | 25-800 | 4-630 |

| Spindle end | - | A2-8 | A2-11 | A2-15 | A2-15 |

| Diameter of spindle through hole | mm | ф82/105 | ф105/130 | ф130 | ф130 |

| Spindle motor | kW | 11 | 15 | 22 | 22 |

| Ball screw dia.and pitch | - | 3205/5010 | 3205/6310 | 4006/6310 | 5008/8012 |

| X/Z axis teed motor torque | N.m | 10/15 | 10/18 | 18/22 | 18/22 |

| X/Z Rapid traverse | m/min | 6/8 | 6/8 | 4/6 | 4/6 |

| X/Z axis repeatability | mm | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

| Processing accuracy | - | IT6-IT7 | IT6-IT7 | IT6-IT7 | IT6-IT7 |

| Hardness of bed guide rail | - | HRC54 | HRC54 | HRC54 | HRC54 |

| Tailstock sleeve dia. | mm | ф80 | ф100 | ф130 | ф160 |

| Quill traverse | mm | 190 | 250 | 300 | 300 |

| Sleeve taper | # | MT5 | MT6 | MT6 | MT6 |

| Tool post form | - | Four-station electric tool rest | Four-station electric tool rest | Four-station electric tool rest | Four-station electric tool rest |

| Cutting tool shape size | mm | 32x32 | 32x32 | 45x45 | 45x45 |

| Machine dimension(LxWxH) | m | 2.8/3.5/4.1/4.9x1.67x1.8 | 3.8/5.6x2.05x1.78 | 4.6x2.0x2.04 | 4.8x2.3x2.3 |

| Net.weighe(about) | t | 3.2/3.6/3.9 | 5.5/6.8 | 7.5 | 9.5 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.