Multi-Function Slant Bed CNC Lathe for High-Quality Metal Parts Production

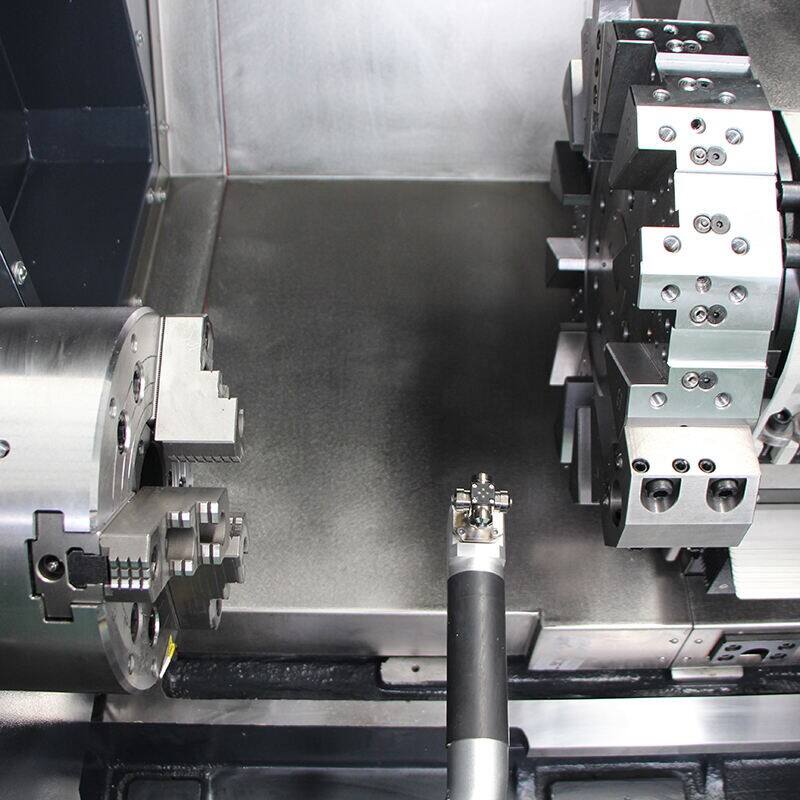

- High precision Roller linear guide

- High precision ball screw

- Imported precision bearing

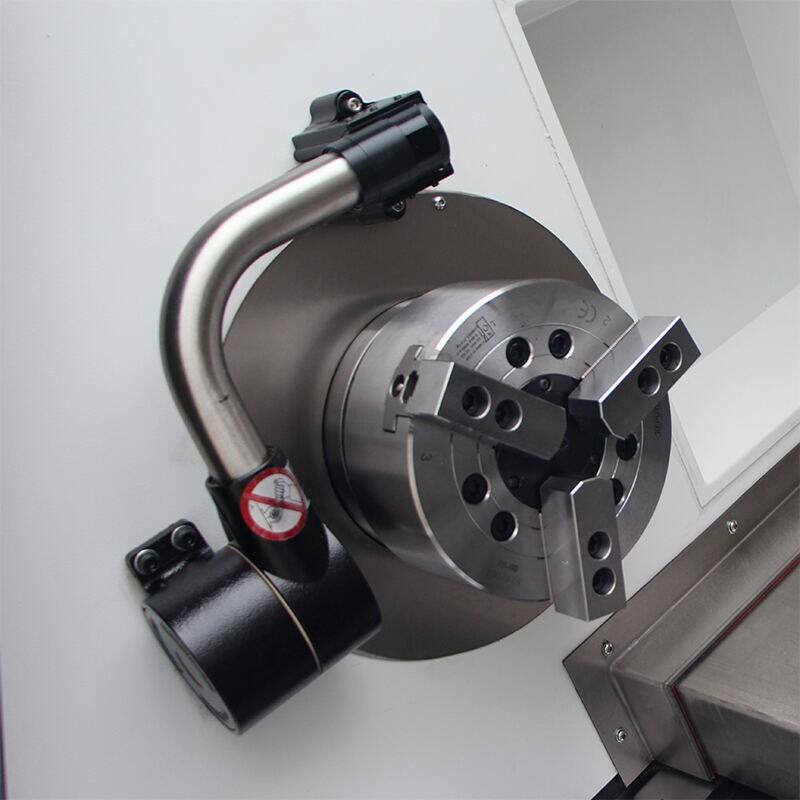

- Optional combined power milling head

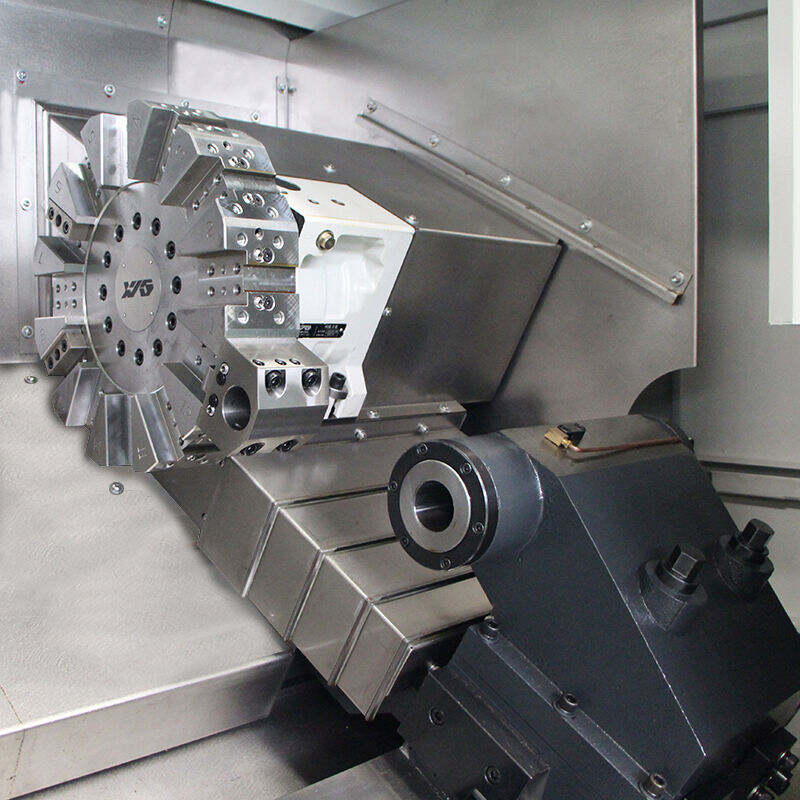

- Optional multi station turret

- Optional 12 Station live tooling y-axis

- Main shaft synchronous belt drive

Introduction

The Multi-Function Slant Bed CNC Lathe by DONGS CNC is designed to deliver exceptional precision and efficiency for modern machining needs. With its robust structure and advanced CNC controls, this lathe is the ideal solution for high-quality metal parts production. The slant bed design enhances stability, reduces vibration, and ensures seamless performance for intricate machining tasks. Whether you're producing prototypes or engaging in mass production, this machine offers the reliability and versatility needed for industrial success.

Key Features:

- High Precision: Achieves tight tolerances and superior surface finishes for intricate designs.

- Durable Slant Bed Structure: Provides excellent rigidity and stability during heavy-duty operations.

- Advanced CNC Control: Features an intuitive interface for easy programming and automation.

- Versatility: Capable of machining various materials, including steel, aluminum, and alloys.

- High-Speed Performance: Equipped with a powerful spindle for efficient and precise operations.

- Customizable Options: Tailor-made configurations to meet specific manufacturing requirements.

Applications:

- Automotive Industry: Ideal for producing components such as engine parts, shafts, and gears.

- Aerospace Manufacturing: Ensures precision machining for high-tolerance aerospace parts.

- Medical Device Production: Suitable for creating surgical instruments and medical implants.

- General Metalworking: Efficiently handles turning, threading, and other machining tasks.

- Tool and Die Making: Perfect for crafting precision tools and molds for various industries.

- Marine Components: Reliable for machining heavy-duty parts like propeller shafts and fittings.

| CAPACITY | Unit | TCK40 | TCK46 | TCK50 |

| Distance between centers | mm | / | ||

| Chuck size | inck | 6 | 8 | |

| Max. swing over bed | mm | 400 | 460 | 510 |

| Max. swing over cross slide | mm | 125 | 150 | 180 |

| Linear guide rail width | mm | 25/30 | 30/30 | 35 |

| TRAVELS | ||||

| X-Axis Rapid Traverse | m/min | 24 | 24 | 24 |

| Z-Axis Rapid Traverse | m/min | 24 | 24 | 24 |

| X axis travel | mm | 800 | 900 | 1100 |

| Z axis travel | mm | 400 | 340 | 500 |

| MAIN SPINDLE | ||||

| Max. Spindle Speed | rpm | 4500 | 4500 | 4200 |

| Max. Spindle Power | kw | 5.5 | 7.5 | 11 |

| Spindle nose | - | A2-5 | A2-5 | A2-6 |

| bar capacity | mm | 41 | 46 | 52 |

| TURRET | ||||

| No. of tool station | - | 8 | 8 | 8 |

| Turret Type | - | Cutting tool/8-station turret | 12-station hydraulic servo turret | |

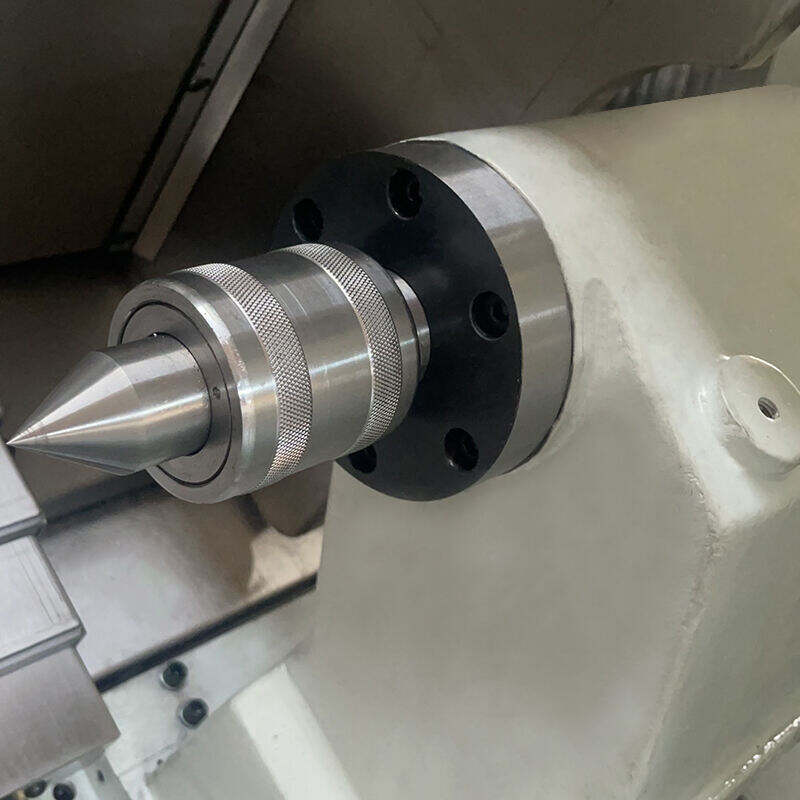

| tailstock | ||||

| quill diameter | mm | NO | ||

| quill travel | mm | |||

| tailstock Travel | mm | |||

| tailstock taper | - | |||

| DIMENSIONS | ||||

| Packing size | m | 2.3 | 2.5 | 2.9 |

| Width | m | 1.6 | 1.7 | 2 |

| Height | m | 2.2 | 2.2 | 2.3 |

| NET Weight | kg | 1700 | 2450 | 2850 |