Heavy-Duty CNC Vertical Lathe for Aerospace, Automotive, and Industrial Applications

Taiwan High precision wire rail, lead screw

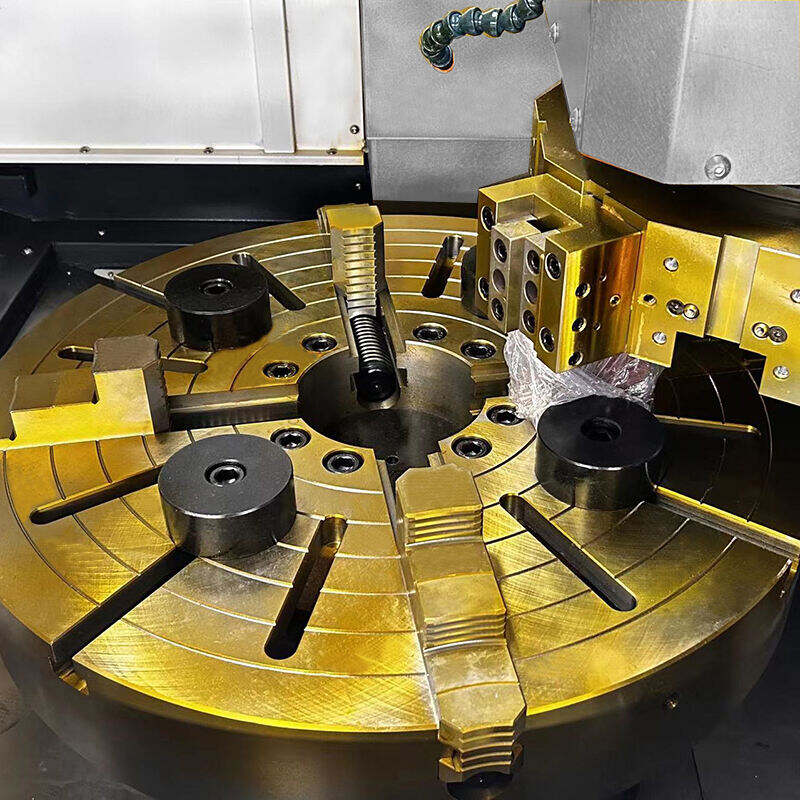

Taiwan hydraulic chuck

Taiwan brand spindle

Taiwan brand turret

Volumetric lubrication

Chain chip conveyor

Three-color alarm light, foot switch, electric cabinet air conditioner

Inner protection of lead screw wire rail

Fully protective sheet metal cover, pneumatic sliding door

Matching hydraulic station

The spindle can add C axis and equipped with power turret

Introduction

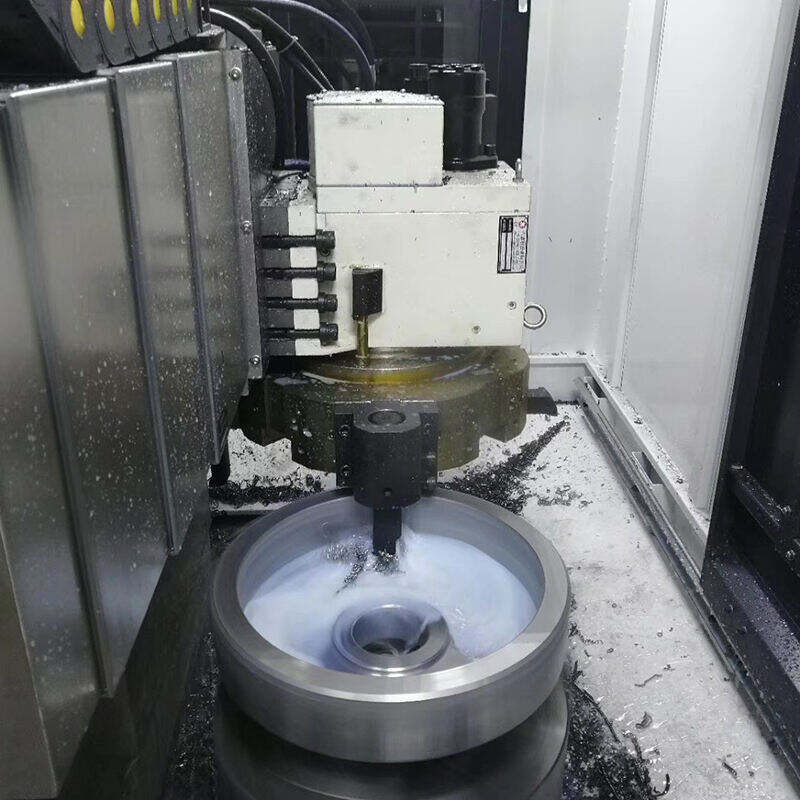

The DONGS CNC Heavy-Duty Vertical Lathe is engineered for high-performance machining in demanding industries such as aerospace, automotive, and heavy equipment manufacturing. With advanced CNC control technology and a robust design, this vertical lathe delivers exceptional precision and reliability, even under the toughest conditions. It is specifically built to handle large, complex workpieces with high material removal rates, making it ideal for machining heavy-duty components.

This machine is designed for versatility, capable of performing a wide range of operations, including turning, boring, milling, and drilling. Whether you're working with steel, aluminum, or other high-strength materials, the DONGS CNC Vertical Lathe ensures superior surface finishes and precise dimensional accuracy. The machine's user-friendly interface, powerful spindle motor, and customizable configurations make it an essential tool for industries requiring maximum efficiency and productivity.

Key Features:

- Heavy-Duty Construction: Built to withstand the rigors of high-material removal rates and tough workpieces.

- Advanced CNC Control: Equipped with state-of-the-art CNC systems that ensure high precision and ease of operation.

- High Spindle Speed & Torque: Provides powerful cutting capabilities for faster production and improved efficiency.

- Versatile Machining Operations: Capable of performing turning, boring, milling, drilling, and more, all in one machine.

- Large Capacity: Available in various sizes (VTC-850, VTC-1000, VTC-1250, VTC-1600) to accommodate large and heavy workpieces.

- Customizable Options: Tailor the machine with specific features like automatic tool changers, advanced cooling systems, and enhanced spindle configurations.

- Precision Performance: Delivers consistent machining accuracy and high-quality surface finishes.

- Durability & Reliability: Designed for long-term use with minimal maintenance requirements, offering high uptime and productivity.

- Safety Features: Built with enhanced safety protocols, including overload protection and operator-friendly interfaces.

- Energy-Efficient: Optimized for power savings while maintaining high-performance standards.

Applications:

- Aerospace Manufacturing: Machining of complex, high-precision components such as turbine blades, engine housings, and landing gear parts.

- Automotive Industry: Ideal for producing large engine blocks, crankshafts, gears, and other critical components that require precision and heavy material removal.

- Heavy Equipment Manufacturing: Perfect for machining parts like machine housings, drive shafts, and large structural components.

- Energy and Power Generation: Machining large parts like turbine casings, pump components, and pressure vessels for power plants and refineries.

- Marine Industry: Manufacturing ship parts such as propellers, rudders, and large engine components that need to withstand harsh environments.

- Tool and Die Making: Precision machining of molds, dies, and cutting tools for manufacturing processes.

- Metalworking: Suitable for machining large workpieces, including flanges, plates, and industrial machinery parts.

- Railroad & Infrastructure: Ideal for machining large components used in trains, tracks, and other critical infrastructure projects.

| Specifications | Unit | VTC850 | VTC1000 |

| Maximum rotation diameter of workpiece | mm | 900 | 1000 |

| Maximum machining diameter | mm | 850Plate 700cylinder | 900 |

| Hydraulic chuck diameter | mm | 630 | 800 |

| Spindle speed | rpm | 50-800/ 1:2.5(gear ratio) | 50-800 |

| Spindle model | - | A2-11 | A2-11 |

| Spindle output torque | NM | 875 | 1050 |

| Vertical movement distance of tool carrier | mm | 750 | 700 |

| Horizontal moving distance of tool rest | mm | -50-550 | -50-550 |

| Track width | mm | 55pin roller | 55Heavy duty roller |

| X/Z-axis fast moving speed | m/min | 15/12 | 15/12 |

| Turret form | - | 8Station servo turret/four-station/cutter arrangement | |

| Cutter bar section | mm | 32×32 | 32×32Boring tool holder 40/50 |

| Main motor power | kw | 22-30(Low frequency high torsion) | 22-30(Low frequency high torsion) |

| XPower and torque of feed motor | kw/nm | 2.4 /15 | 2.8/18 |

| ZPower and torque of feed motor | kw/nm | 2.8/18 | 2.8/18 |

| Diameter of X / Z axis ball screw | mm | 4010/5010 | 5010/5010 |

| Repeated positioning accuracy of machine tool | mm | ±0.005 | ±0.005 |

| The weight of the machine tool is about | T | 8.8 | 10.8 |

| Outline dimension of machine tool | m | 2.8×2.0×3.2 | 2.9×2.9×3.5 |

| Specifications | Unit | VTC1250 | VTC1400 | VTC1600 |

| Maximum rotation diameter of workpiece | mm | 1250 | 1400 | 1600 |

| Maximum machining diameter | mm | 1050 | 1250 | 1400 |

| Spindle speed | rpm | 20-500Double speed gear box | 20-400Double speed gear box | 20-350Double speed gear box |

| Vertical movement distance of tool carrier | mm | 800 | 800 | 800 |

| Horizontal moving distance of tool rest | mm | -50-650 | -50-750 | -50-850 |

| X-axis fast moving speed | m/min | 15 | 15 | 15 |

| Z-axis fast moving speed | m/min | 12 | 12 | 12 |

| Turret form | - | Vertical 4 station | Vertical 4 station | Vertical 4 station |

| Cutter bar section | mm | Φ32/50 | Φ32/50 | Φ32/50 |

| Main motor power | kw | 22/30 | 22/30 | 30/37 |

| Hydraulic chuck diameter | mm | Manual four-jaw chuck1000 | Manual four-jaw chuck1250 | Manual four-jaw chuck1400 |

| X/Z Power and torque of feed motor | kw/nm | 3.5/22 | 3.5/22 4.7/30 | 4.7/30 |

| X/Z Linear guide rail | mm | 65/55pin roller | 65/55pin roller | 65pin roller |

| X/Z lead screw diameter | mm | Φ50 | Φ50 | Φ63 |

| The weight of the machine tool is about | t | 12.8 | 13.8 | 15.5 |

| Outline dimension of machine tool | m | 2.7×2.85×3.25 | 2.8×2.95×3.25 | 3.0×3.0×3.25 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.