Affordable and High-Performance Turning Centers for Cost-Efficient Manufacturing

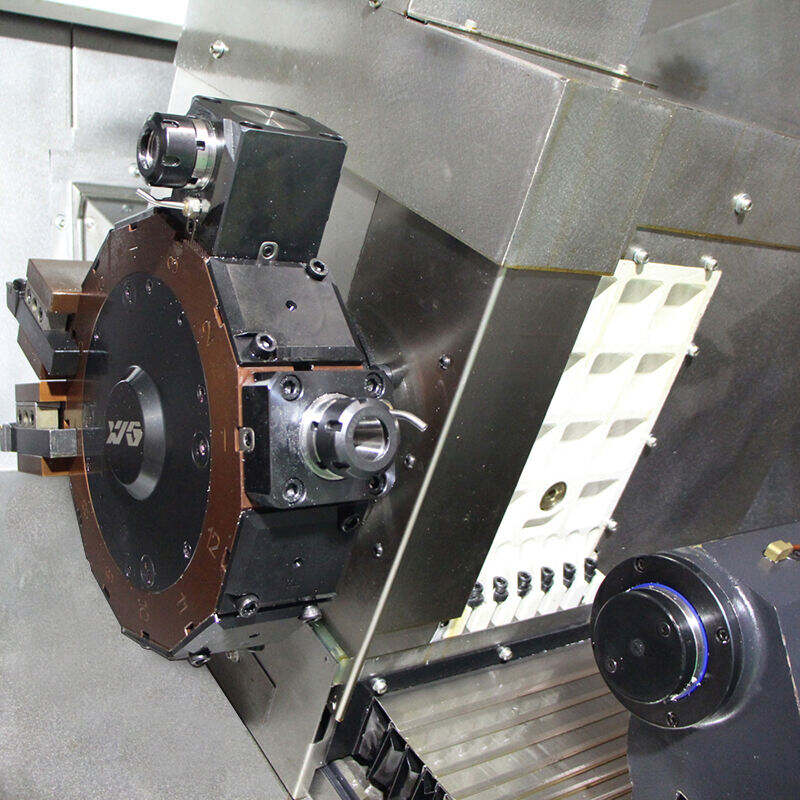

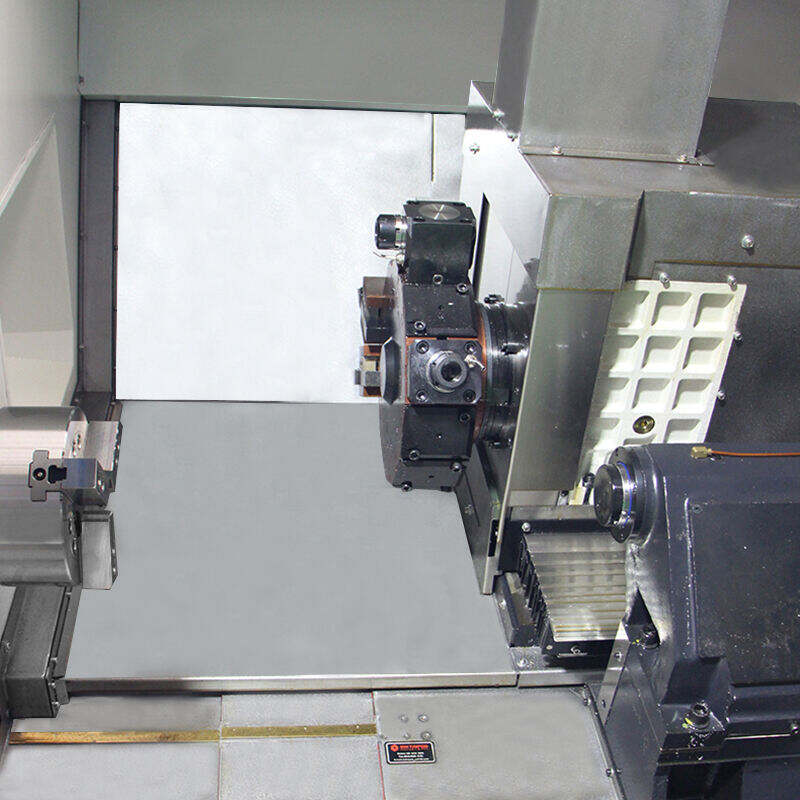

- High precision ball screw

- High precision Roller linear guide

- 12-station powered turret

- Magnetic ring encoder

- Hydraulic programming tailstock

- A2-6/A2-8 heavy duty spindle

Introduction

The DONGS CNC Horizontal Turning Center is designed to deliver exceptional precision and performance in high-volume, cost-efficient manufacturing processes. Built for versatility, these turning centers offer a perfect solution for producing complex metal parts with high accuracy. Featuring an advanced CNC control system and a robust, rigid design, these machines are ideal for industries where reliability, speed, and cost-effectiveness are crucial. With a focus on minimizing operational costs while maximizing output, this turning center is a valuable addition to any workshop aiming for superior efficiency in production.

Key Features:

- High Precision: Equipped with advanced CNC control technology, ensuring accurate machining for intricate parts.

- Heavy-Duty Construction: Built with a strong, rigid frame to handle heavy loads and reduce vibrations, ensuring stable operations.

- Cost-Effective Production: Designed for high-speed turning, reducing cycle times and operational costs, making it perfect for mass production.

- User-Friendly Interface: Simplified controls that make it easy for operators to set up and manage operations with minimal training.

- Flexible Tooling Options: Offers compatibility with various cutting tools, enhancing versatility in machining different materials.

- Automatic Tool Changer: Reduces downtime between operations, ensuring continuous, efficient machining.

- Energy-Efficient: Incorporates energy-saving technology that reduces power consumption without compromising performance.

- Easy Maintenance: Features a low-maintenance design, reducing downtime and improving overall productivity.

Applications:

- Automotive Parts Manufacturing: Perfect for producing automotive components such as shafts, hubs, gears, and engine blocks with high precision.

- Aerospace Industry: Ideal for manufacturing critical aerospace parts that require tight tolerances and high-quality finishes.

- Heavy Machinery Manufacturing: Suitable for machining large components used in construction equipment and industrial machinery.

- Oil and Gas Industry: Used for producing parts such as valves, fittings, and drill equipment for the oil and gas sector.

- General Metalworking: Provides solutions for turning operations in general manufacturing, such as producing machine parts, tools, and other precision components.

- Tool and Die Making: Ideal for machining tools and dies for the production of molded parts.

- Energy Sector: Essential for producing components used in power generation and renewable energy equipment.

| CAPACITY | Unit | TCK52DY |

| Distance between centers | mm | 650/850 |

| Chuck size | inck | 8/10 |

| Max. swing over bed | mm | 670 |

| Max. swing over cross slide | mm | 400 |

| Linear guide rail width | mm | 45/45 |

| TRAVELS | ||

| X-Axis Rapid Traverse | m/min | 24 |

| Z-Axis Rapid Traverse | m/min | 24 |

| X axis travel | mm | 260 |

| Z axis travel | mm | 650/850/1270 |

| Y axis travel | mm | ±45 |

| MAIN SPINDLE | ||

| Max. Spindle Speed | rpm | 4200/3500 |

| Max. Spindle Power | kw | 11 |

| Spindle nose | - | A2-6/A2-8 |

| bar capacity | mm | 52/65/75 |

| TURRET | ||

| No. of tool station | - | 12 |

| Turret Type | - | 12 Station live tooling(BMT55) |

| Rotary Tool | r/min | 5000 |

| tailstock | ||

| quill diameter | mm | 80 |

| quill travel | mm | 80 |

| tailstock Travel | mm | 490/740/990 |

| tailstock taper | - | MT5 |

| DIMENSIONS | ||

| Packing size | m | 4 |

| Width | m | 2 |

| Height | m | 2.5 |

| NET Weight | kg | 4800 |