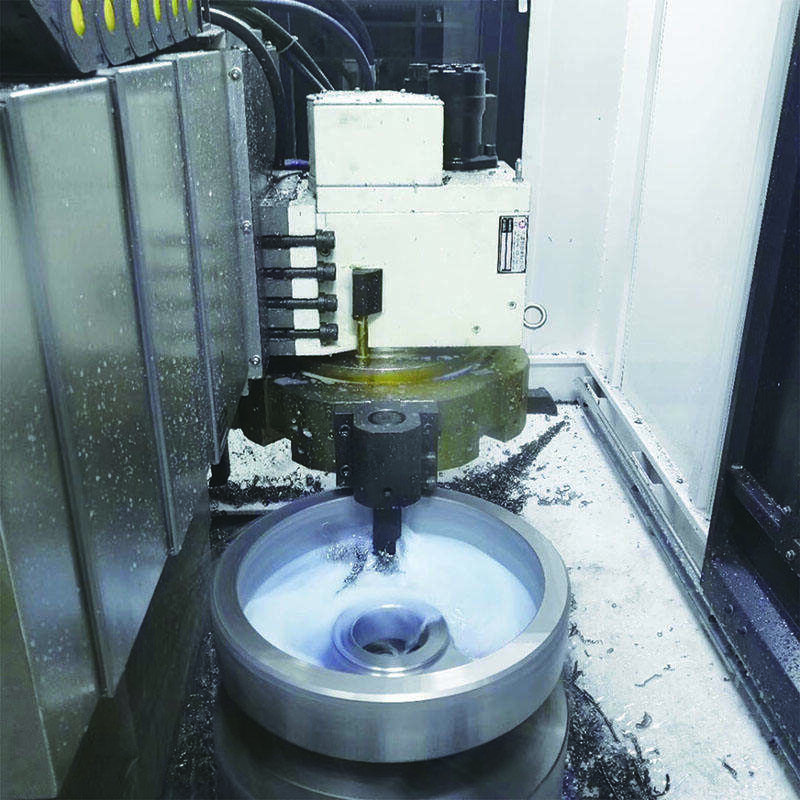

Customizable CNC Vertical Lathe for Efficient and Accurate Machining Operations

-

Taiwan High precision wire rail, lead screw

-

Taiwan hydraulic chuck

-

Taiwan brand spindle

-

Taiwan brand turret

-

Volumetric lubrication

-

Chain chip conveyor

-

Three-color alarm light, foot switch, electric cabinet air conditioner

-

Inner protection of lead screw wire rail

-

Fully protective sheet metal cover, pneumatic sliding door

-

Matching hydraulic station

-

The spindle can add C axis and equipped with power turret

Introduction

The DONGS CNC Vertical Lathe offers a customizable solution for precision machining, designed to meet the rigorous demands of various industries. With its advanced CNC technology, this vertical lathe provides outstanding efficiency, accuracy, and versatility for turning, boring, and milling operations. Ideal for machining large, heavy, and complex components, it is perfect for industries such as aerospace, automotive, and heavy equipment manufacturing.

This machine is engineered for high productivity with minimal downtime, thanks to its robust design, superior cutting performance, and intuitive control system. The DONGS CNC Vertical Lathe ensures tight tolerances, exceptional surface finishes, and the capability to handle multiple operations with ease, all while maintaining cost-effectiveness. Customizable options, including different workpiece sizes and automated systems, provide maximum flexibility to fit specific production needs.

Key Features:

- High Precision: Equipped with high-accuracy CNC control systems for tight tolerances and smooth finishes.

- Heavy-Duty Construction: Built to handle large, heavy components with a durable and rigid design.

- Versatile Operations: Supports turning, boring, milling, and other processes, enabling efficient multi-tasking.

- Customizable Configuration: Available in various sizes (VTC-850, VTC-1000, VTC-1250, VTC-1600) to match your production needs.

- Advanced Control System: Features a user-friendly CNC interface with intuitive programming for quick setups.

- Increased Productivity: High spindle speed and feed rate for faster machining cycles.

- Energy Efficient: Designed to reduce power consumption without compromising on performance.

- Automatic Tool Change: Optional tool magazine for reduced downtime and improved automation.

- Improved Accuracy: Minimal vibration and thermal distortion for precise machining on all types of materials.

- Safety Features: Enhanced safety protocols to protect operators and machinery.

Applications:

- Aerospace Industry: Machining complex parts such as turbine blades, aircraft fuselage components, and engine parts with tight tolerances.

- Automotive Manufacturing: Ideal for producing engine components, gears, crankshafts, and suspension parts requiring high precision.

- Energy Sector: Manufacturing power generation parts, including turbines, pump casings, and compressors.

- Heavy Machinery Production: Precision machining of parts for industrial machines like gears, shafts, and housings.

- Marine Industry: Ideal for machining ship components such as propellers, rudders, and large engine blocks.

- Medical Equipment Manufacturing: Producing high-precision medical components, including implants and surgical tools.

- Tool and Die Making: Perfect for creating molds, dies, and cutting tools for manufacturing processes.

| Specifications | Unit | VTC500 | VTC650 | VTC750 |

| Maximum rotation diameter of workpiece | mm | 500 | 650 | 750 |

| block type | mm | 400 | 550 | 650 |

| Hydraulic chuck | inch | 12" | 15" | 21" |

| Spindle speed | rpm | 50-1250 | 50-1250 | 50-1000 |

| Spindle model | - | A2-8 | A2-8 | A2-11 |

| feed rate | mm/min | 0.1-5000 | 0.1-5000 | 0.1-5000 |

| Vertical movement distance of tool carrier | mm | 500 | 550 | 700 |

| Horizontal moving distance of tool rest | mm | -50-275 | -50-325 | -50-375 |

| Linear guide rail | mm | 45pin roller | 45pin roller | 55pin roller |

| X/Z-axis fast moving speed | m/min | 15/12 | 15/12 | 15/12 |

| Turret form | - | Horizontal station 12 | Horizontal type 8 station | Horizontal station 8/vertical station 4 |

| Main motor power | kw | 11/15 | 15/18.5 | 22/30-286 |

| X/Z Power聽 of feed motor | kw | 1.6/2.4 | 2.4/2.4 | 2.4/2.8 |

| X/Z lead screw diameter | mm | Φ40 | Φ40 | Φ40/50 |

| Repeated positioning accuracy of machine tool | mm | ±0.005 | ±0.005 | ±0.005 |

| Outline dimension of machine tool | m | 1.8×1.8×2.5 | 1.95×1.85×2.65 | 2.3×2×2.3 |

| Overall weight (about) | t | 4.2 | 5.2 | 7.2 |