High-Capacity CNC Turning Centers for Reliable and Efficient Machining of Heavy Parts

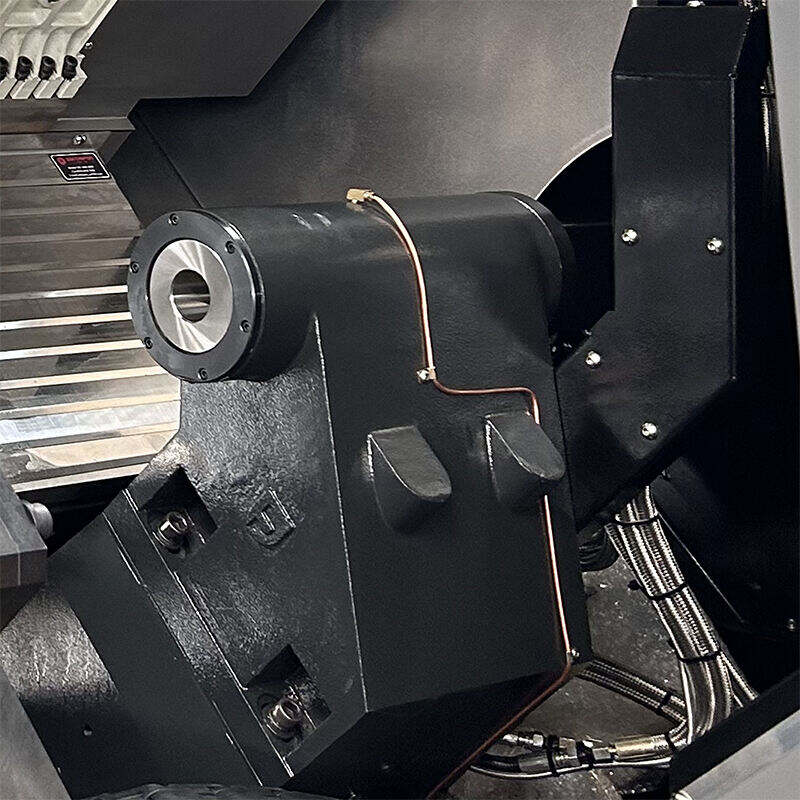

- High precision Roller linear guide

- High precision ball screw

- lmported precision bearing

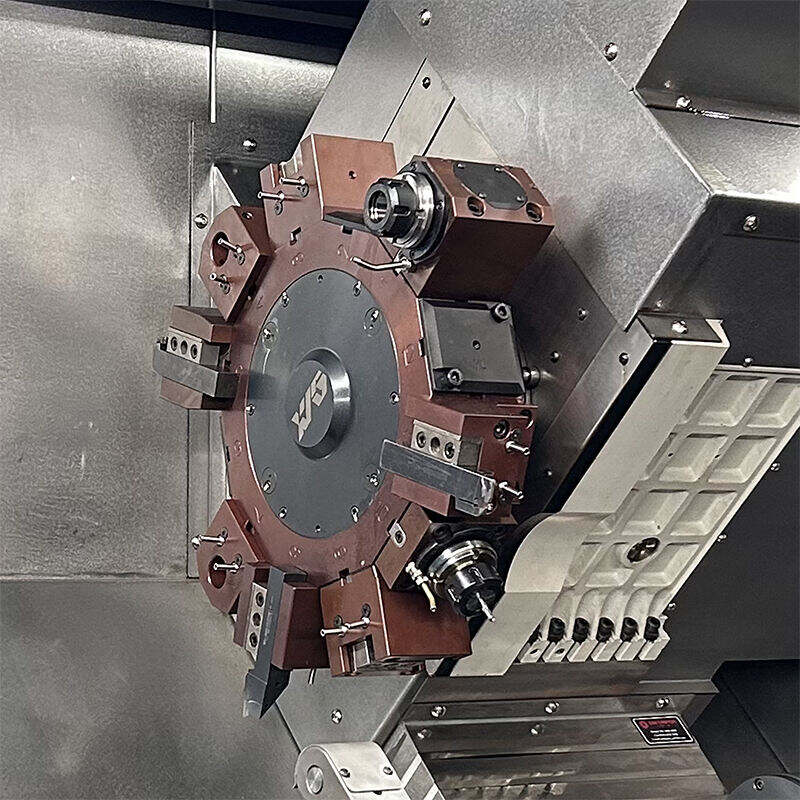

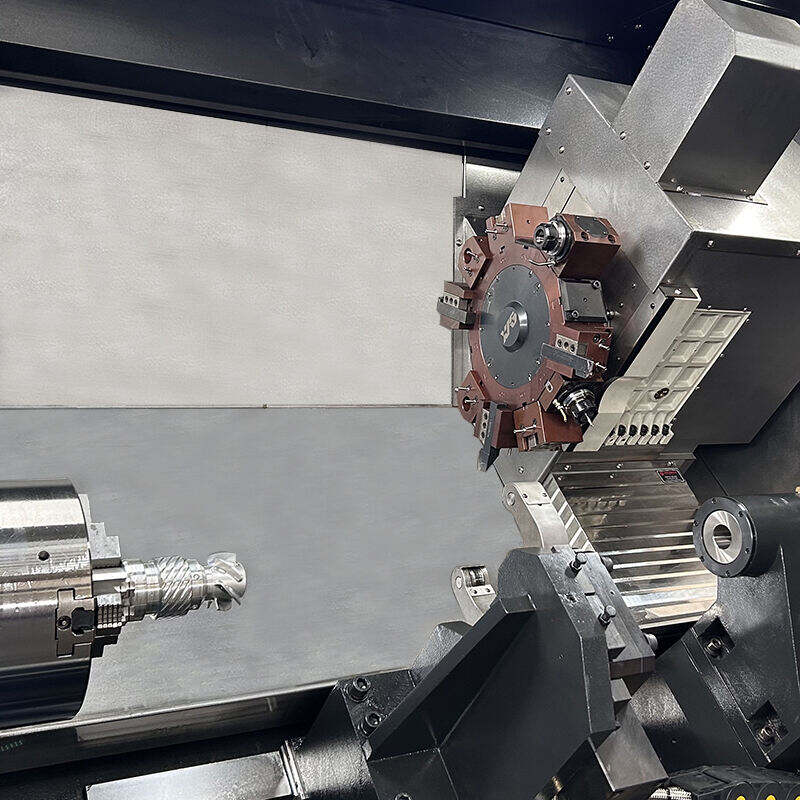

- Servo hydraulic turret

- 12 Station live tooling

- Tool setting instrument is optional

Introduction

The High-Capacity CNC Turning Centers from DONGS CNC are engineered for the precise and efficient machining of heavy parts in various industries. With a robust build and advanced CNC technology, these turning centers offer exceptional performance in handling large workpieces that require high tolerance and precision. Designed for heavy-duty operations, these machines are ideal for production environments where reliability and efficiency are paramount. Whether for small batch production or high-volume manufacturing, our horizontal turning centers are built to meet the demands of complex and heavy machining tasks.

Key Features:

- High Load Capacity: Designed to handle large, heavy workpieces, ensuring stable and reliable performance under demanding conditions.

- Advanced CNC Control: Equipped with state-of-the-art CNC control systems, providing high precision, ease of operation, and customizable machining options.

- Rigid and Durable Construction: Built with a heavy-duty cast iron frame and precision-engineered components to withstand the rigors of high-capacity turning operations.

- Large Workpiece Capacity: Capable of machining parts with larger diameters and longer lengths, making it perfect for industries requiring large parts.

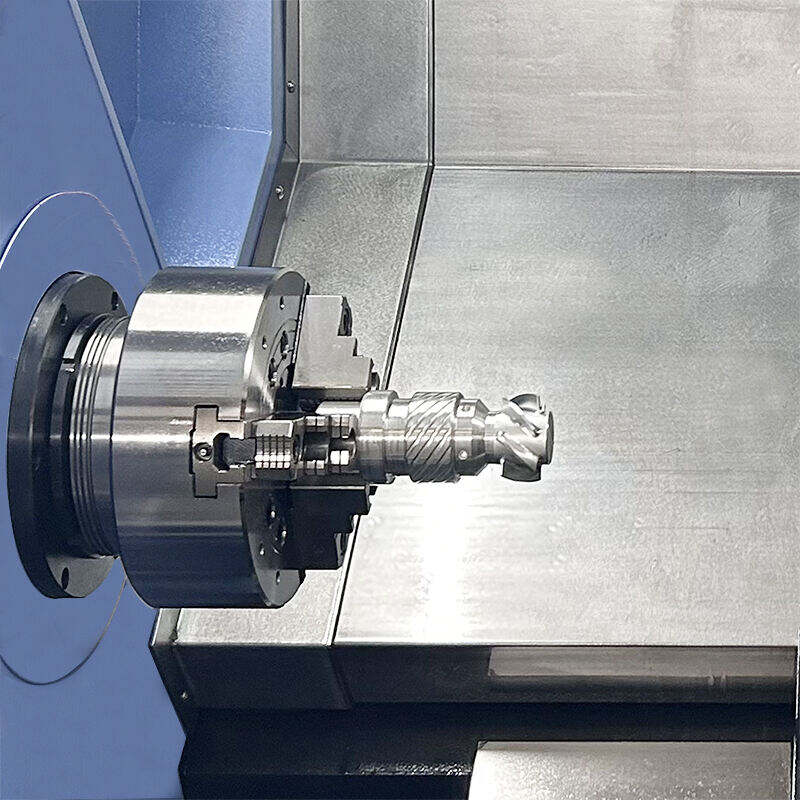

- High-Precision Spindle: Features a powerful spindle capable of maintaining high-speed cutting while ensuring precision in every turn.

- Improved Tool Life: Equipped with automatic tool changers and optimized tool paths, reducing downtime and increasing overall productivity.

- User-Friendly Interface: Easy-to-use interface for operators, improving workflow efficiency and reducing learning curves.

- Energy Efficient: Engineered for optimal power consumption without compromising performance, helping to reduce operational costs.

Applications:

- Heavy Machinery Manufacturing: Ideal for machining large components like gears, shafts, and housings used in heavy machinery production.

- Automotive Industry: Perfect for the production of automotive parts such as engine blocks, crankshafts, and large transmission components.

- Aerospace and Defense: Used for manufacturing critical aerospace components such as turbine blades, aircraft frames, and large engine parts with high precision.

- Oil & Gas: Suitable for machining large components for the oil and gas industry, including valves, pumps, and pressure vessels.

- Energy Sector: Machining parts for energy production, including turbine rotors, generator components, and other heavy-duty machinery.

- General Manufacturing: Ideal for industries that require the machining of large, heavy parts with high precision and efficiency, including industrial pumps and equipment.

- Shipbuilding: Used to produce large components for the shipbuilding industry, such as propellers, rudders, and other structural parts.

| CAPACITY | Unit | TCK600DY |

| Distance between centers | mm | 1100/1500 |

| Chuck size | inck | 10/12 |

| Max. swing over bed | mm | 670 |

| Max. swing over cross slide | mm | 450 |

| Linear guide rail width | mm | 45/45 |

| TRAVELS | ||

| X-Axis Rapid Traverse | m/min | 24 |

| Z-Axis Rapid Traverse | m/min | 24 |

| X axis travel | mm | 315 |

| Z axis travel | mm | 1000/1500 |

| Y axis travel | mm | ±50 |

| MAIN SPINDLE | ||

| Max. Spindle Speed | rpm | 3000/2500 |

| Max. Spindle Power | kw | 22 |

| Spindle nose | - | A2-8 |

| bar capacity | mm | 74/92 |

| TURRET | ||

| No. of tool station | - | 12 |

| Turret Type | - | 12 Station live tooling(BMT55) |

| Rotary Tool | r/min | 5000 |

| tailstock | ||

| quill diameter | mm | 100 |

| quill travel | mm | 100 |

| tailstock Travel | mm | 900/1400 |

| tailstock taper | - | MT5 |

| DIMENSIONS | ||

| Packing size | m | 5.6 |

| Width | m | 2.2 |

| Height | m | 2.5 |

| NET Weight | kg | 6300 |