High-Speed Milling and Turning Machines for Complex Part Machining in Metal Industries

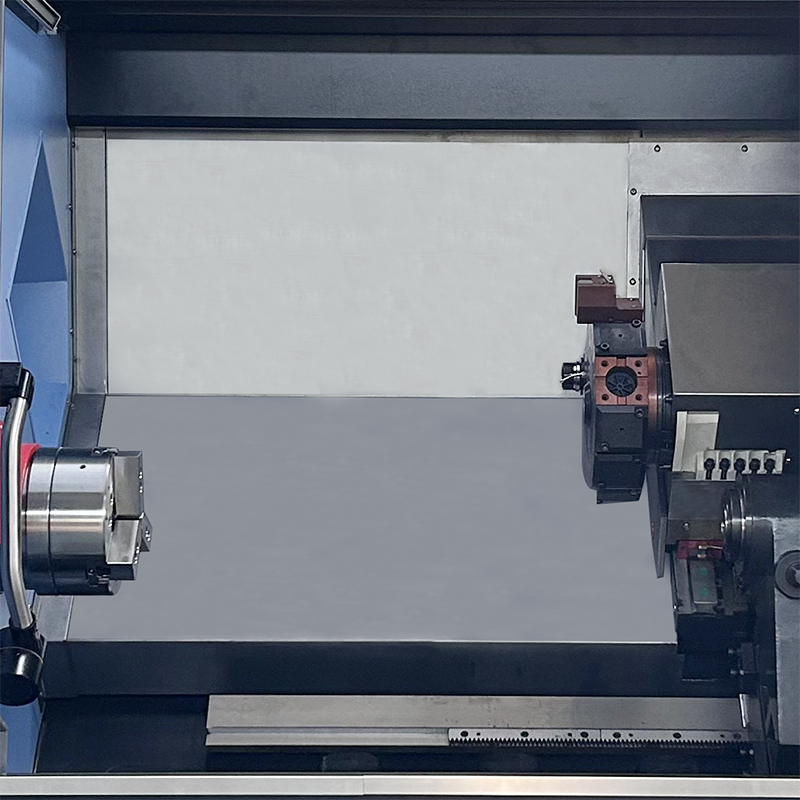

- 45 DEG Table angle

- High precision Roller linear guide

- High precision ball screw

- Imported precision bearing

- Integrated casting frame

- High rigidity heavy-duty single spindle

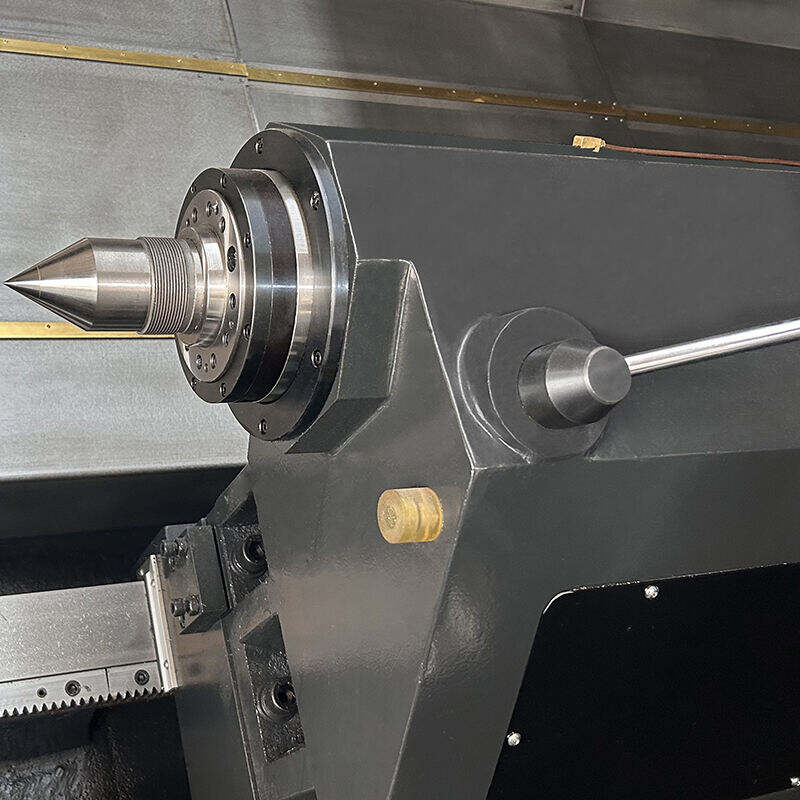

- Hydraulic programmable tailstock

Introduction

The High-Speed Horizontal Turning Center by DONGS CNC is engineered to provide exceptional performance for complex part machining in metal industries. Designed for precision and speed, this machine integrates both turning and milling functions, allowing for superior metalworking on a wide range of materials. Whether you are machining intricate components for aerospace, automotive, or heavy industrial applications, our horizontal turning center offers reliable performance, cutting-edge technology, and excellent efficiency in demanding production environments.

Built to withstand high-precision tasks, this versatile machine is ideal for manufacturers looking to enhance productivity, reduce operational downtime, and maintain high-quality machining standards.

Key Features:

- High-Speed Precision: Capable of delivering precise and accurate cuts at high speeds for maximum efficiency in production.

- Dual Functionality: Combines turning and milling operations, reducing the need for multiple machines and increasing workflow efficiency.

- Advanced CNC Controls: Equipped with user-friendly controls, allowing for easy operation and quick set-up for complex part machining.

- Heavy-Duty Build: Designed with robust components to handle heavy workloads and high-volume production, ensuring durability and long service life.

- Customizable Configuration: Offers flexible configuration options to meet the specific needs of various industries and machining requirements.

- High-Performance Spindle: Enhanced spindle design for superior cutting performance and high torque for heavy-duty machining.

- Efficient Cooling System: Advanced cooling systems designed to maintain optimal operating temperatures and prevent overheating during long machining sessions.

Applications:

- Aerospace: Precision machining of components like turbine blades, brackets, and housings, where accuracy and quality are critical.

- Automotive: Manufacturing of engine components, transmission parts, and structural components requiring high-speed machining and precision.

- Heavy Industry: Machining large-scale parts such as gears, shafts, and other industrial components with tight tolerances.

- Tool and Die Making: Ideal for machining molds, dies, and other precision tools used in production processes.

- Energy & Power Generation: Used for high-precision machining of parts used in the energy sector, including components for turbines, valves, and other critical equipment.

- General Manufacturing: Suitable for producing high-precision parts across a wide range of applications in industries like medical, military, and consumer products.

| CAPACITY | Unit | TCK700-1000 | TCK700-1500 | TCK700-2000 | TCK700-3000 |

| Distance between centers | mm | 1100 | 1600 | 2100 | 3100 |

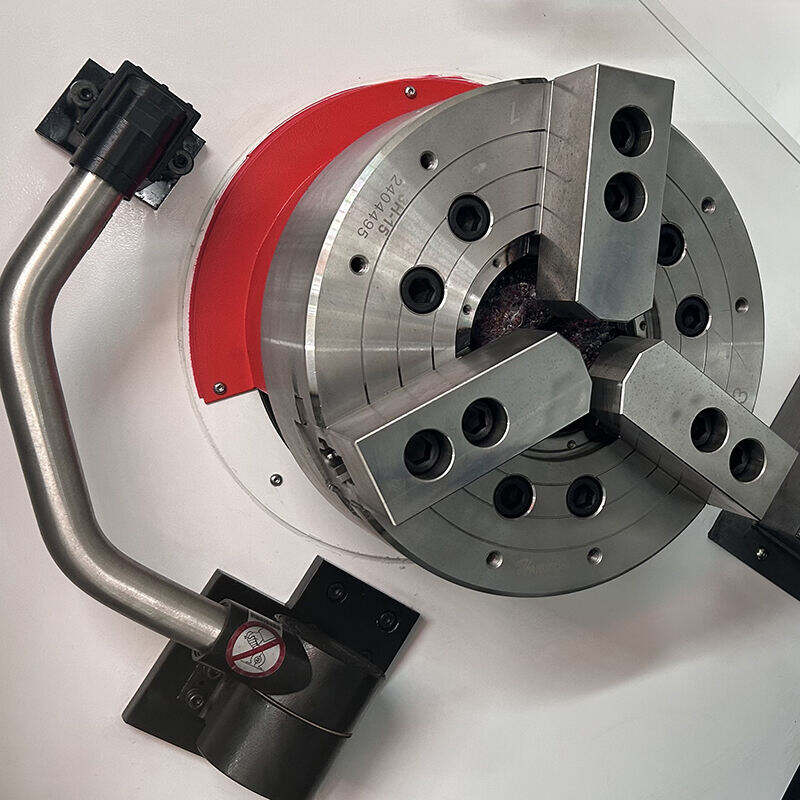

| Chuck size | inck | 15/12/10 | |||

| Max. swing over bed | mm | 780 | |||

| Max. swing over cross slide | mm | 500 | |||

| Linear guide rail width | mm | 55/55 | |||

| TRAVELS | |||||

| X-Axis Rapid Traverse | m/min | 16 | |||

| Z-Axis Rapid Traverse | m/min | 16 | |||

| X axis travel | mm | 350 | |||

| Z axis travel | mm | 1000 | 1500 | 2000 | 3000 |

| MAIN SPINDLE | |||||

| Max. Spindle Speed | rpm | 2000/2500/3000 | |||

| Max. Spindle Power | kw | 30 | |||

| Spindle nose | - | A2-11/A2-8 | |||

| bar capacity | mm | 115/91/75 | |||

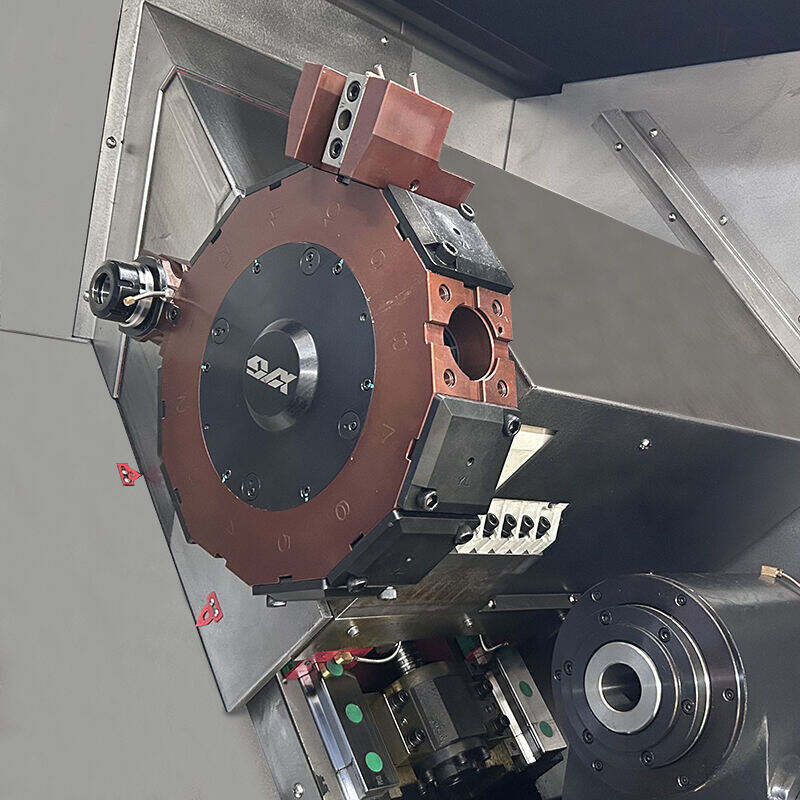

| TURRET | |||||

| No. of tool station | - | 12 | |||

| Turret Type | - | 12 Station live tooling(BMT65) | |||

| Rotary Tool | r/min | 5000 | |||

| tailstock | |||||

| quill diameter | mm | 150 | 160 | ||

| quill travel | mm | 200 | |||

| tailstock Travel | mm | 900 | 1400 | 1900 | 2900 |

| tailstock taper | - | MT5 | MT6 | ||

| DIMENSIONS | |||||

| Packing size | m | 5.3 | 5.8 | 6.3 | 7.3 |

| Width | m | 2.25 | 2.25 | 2.25 | 2.25 |

| Height | m | 2.55 | 2.55 | 2.55 | 2.55 |

| NET Weight | kg | 7500 | 9000 | 11500 | 13000 |