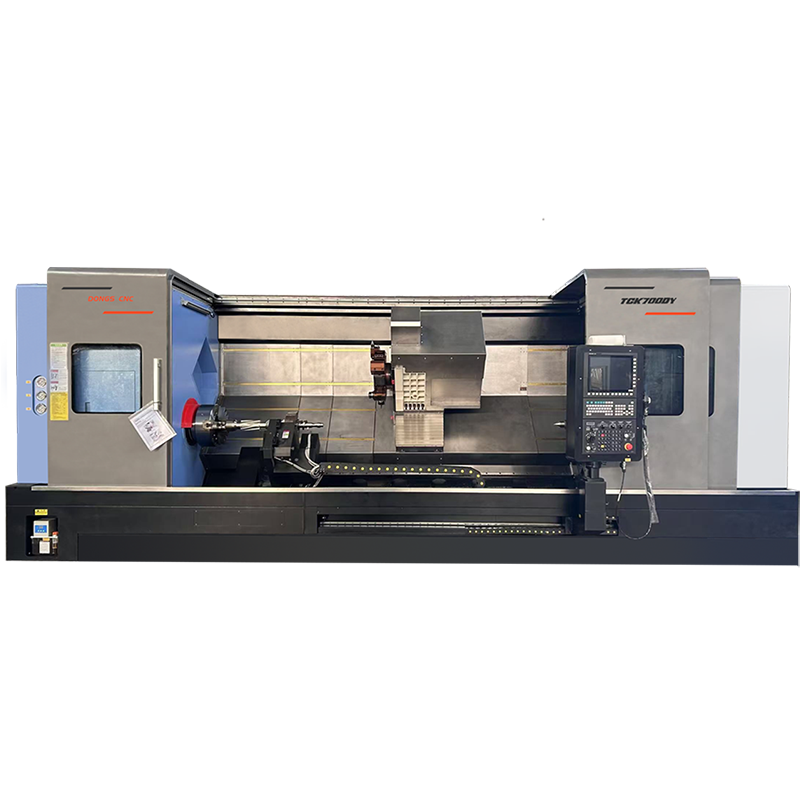

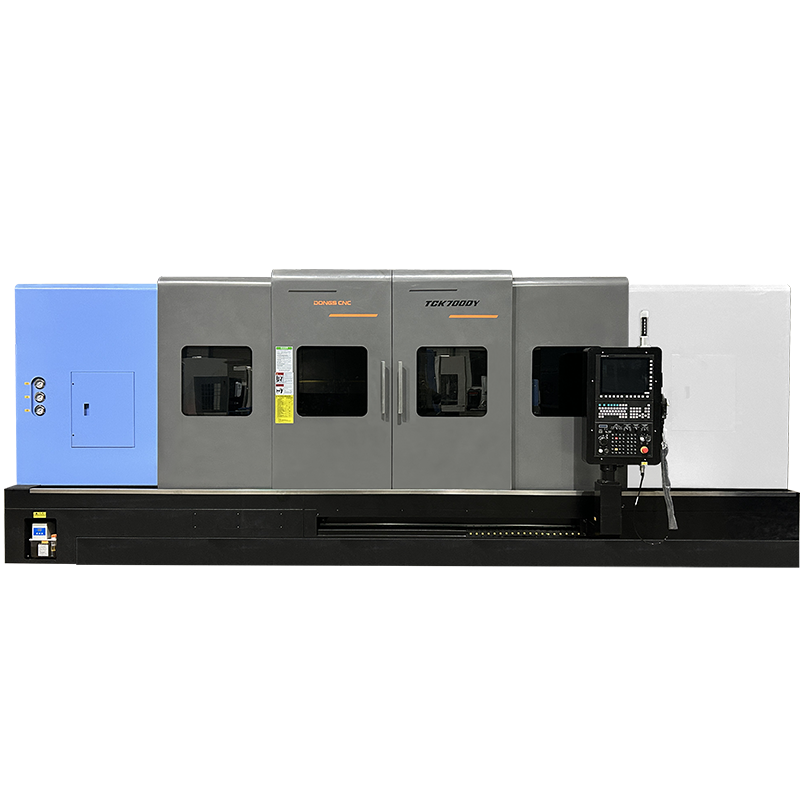

Industrial Strength High-Performance Turning Center for Large Metal Parts

• 45 DEG Table angle

• High precision Roller linear guide

• High precision ball screw

• Imported precision bearing

• Integrated casting frame

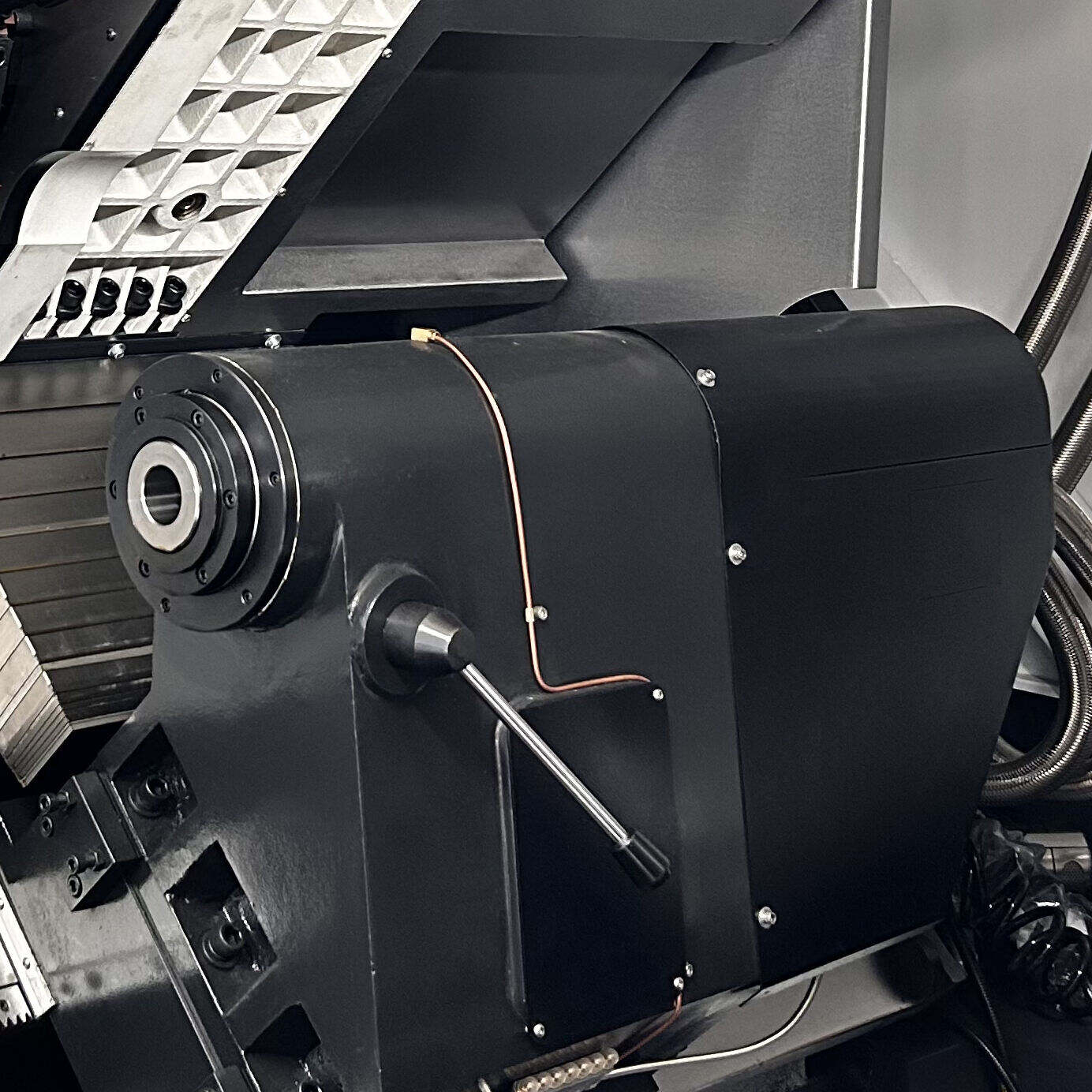

• High rigidity heavy-duty single spindle

• Hydraulic programmable tailstock

Introduction

The Industrial Strength High-Performance Horizontal Turning Center is engineered for the most demanding machining tasks. Designed to handle large metal parts with ease, this horizontal turning center is perfect for industries that require precise, heavy-duty machining operations. With robust construction and advanced technology, it provides exceptional stability, high cutting efficiency, and long-lasting durability. It is ideally suited for turning large and heavy workpieces, making it a vital asset for heavy manufacturing and precision engineering applications.

Key Features:

- High Load Capacity: Capable of machining large and heavy metal parts with a maximum turning diameter and length that suits industrial-grade operations.

- Precision Machining: Provides high accuracy and tight tolerances, ensuring consistent results even in tough materials.

- Heavy-Duty Construction: Built with robust materials to withstand high forces and vibrations during heavy cutting processes.

- Advanced CNC System: Equipped with a state-of-the-art CNC control system for easy operation, fast programming, and enhanced automation.

- Efficient Chip Removal: Features high-efficiency chip removal capabilities, preventing material build-up and ensuring clean machining.

- User-Friendly Interface: Intuitive interface and controls for seamless operation, reducing setup time and minimizing human error.

- Energy-Efficient: Designed to optimize energy consumption while delivering high performance, contributing to lower operational costs.

Applications:

- Aerospace: Machining critical aerospace components such as turbine blades, engine casings, and structural parts.

- Automotive: Ideal for producing large automotive parts, including engine blocks, flywheels, and crankshafts.

- Energy & Power Generation: Perfect for machining large components used in power plants, such as turbine shafts and gearbox housings.

- Shipbuilding: Used for manufacturing large ship components like propellers, rudders, and engine parts.

- Defense: Machining of heavy-duty parts for military vehicles, tanks, and other defense systems.

- General Manufacturing: Suitable for heavy machining of industrial parts, molds, and machine components across various sectors.

| CAPACITY | Unit | TCK700-1000 | TCK700-1500 | TCK700-2000 | TCK700-3000 |

| Distance between centers | mm | 1100 | 1600 | 2100 | 3100 |

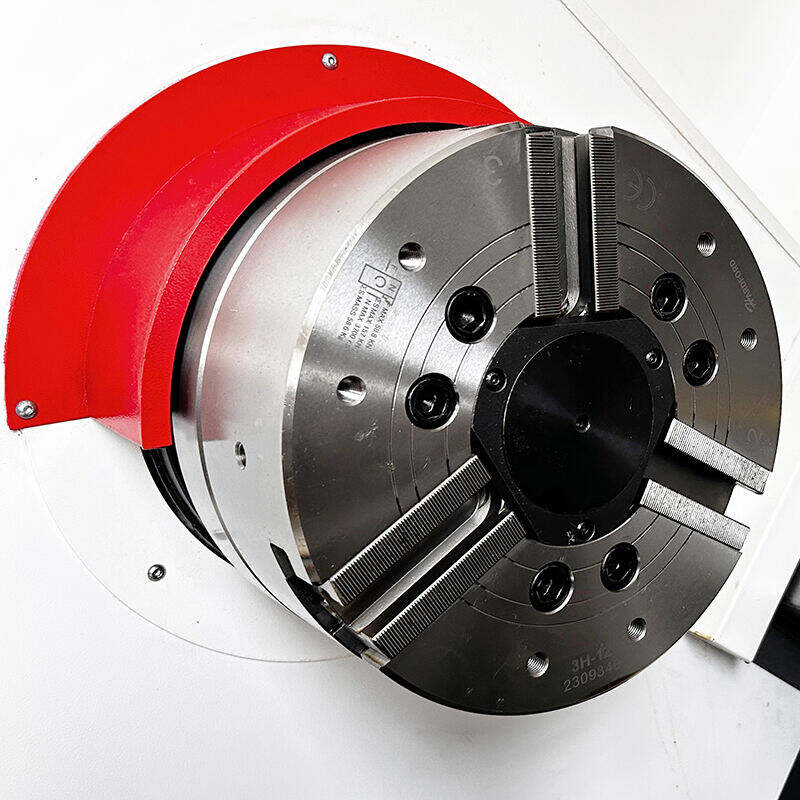

| Chuck size | inck | 15/12/10 | |||

| Max. swing over bed | mm | 780 | |||

| Max. swing over cross slide | mm | 500 | |||

| Linear guide rail width | mm | 55/55 | |||

| TRAVELS | |||||

| X-Axis Rapid Traverse | m/min | 16 | |||

| Z-Axis Rapid Traverse | m/min | 16 | |||

| X axis travel | mm | 350 | |||

| Z axis travel | mm | 1000 | 1500 | 2000 | 3000 |

| Y axis travel | mm | ±75 | |||

| MAIN SPINDLE | |||||

| Max. Spindle Speed | rpm | 2000/2500/3000 | |||

| Max. Spindle Power | kw | 30 | |||

| Spindle nose | - | A2-11/A2-8 | |||

| bar capacity | mm | 115/91/75 | |||

| TURRET | |||||

| No. of tool station | - | 12 | |||

| Turret Type | - | 12 Station live tooling(BMT65) | |||

| Rotary Tool | r/min | 5000 | |||

| tailstock | |||||

| quill diameter | mm | 150 | 160 | ||

| quill travel | mm | 200 | |||

| tailstock Travel | mm | 900 | 1400 | 1900 | 2900 |

| tailstock taper | - | MT5 | MT6 | ||

| DIMENSIONS | |||||

| Packing size | m | 5.3 | 5.8 | 6.3 | 7.3 |

| Width | m | 2.25 | 2.25 | 2.25 | 2.25 |

| Height | m | 2.55 | 2.55 | 2.55 | 2.55 |

| NET Weight | kg | 7500 | 9000 | 11500 | 13000 |