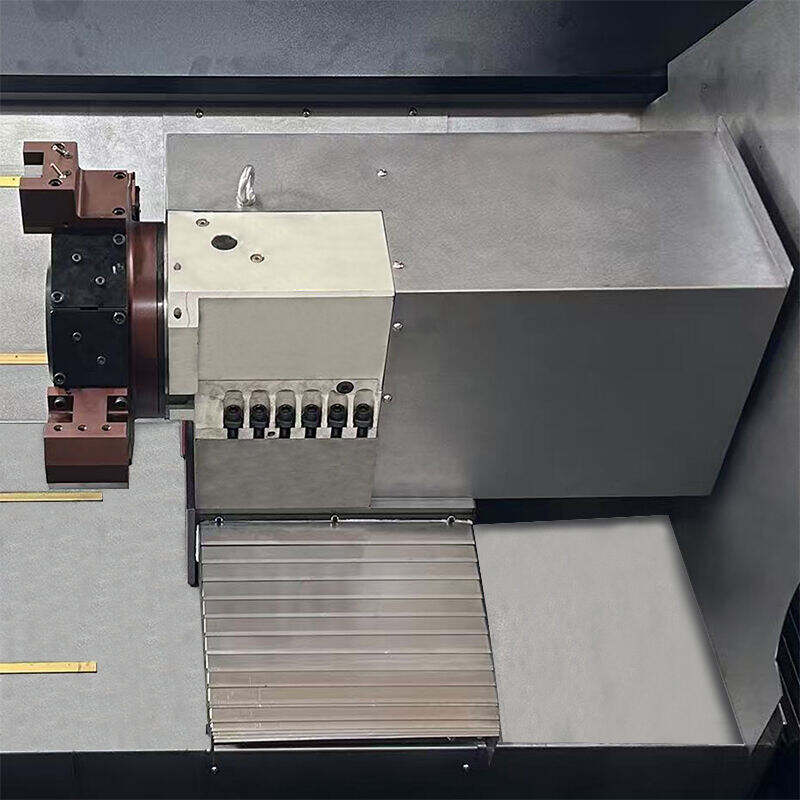

Precision Slant Bed CNC Lathe Turning Centers for Industrial Manufacturing

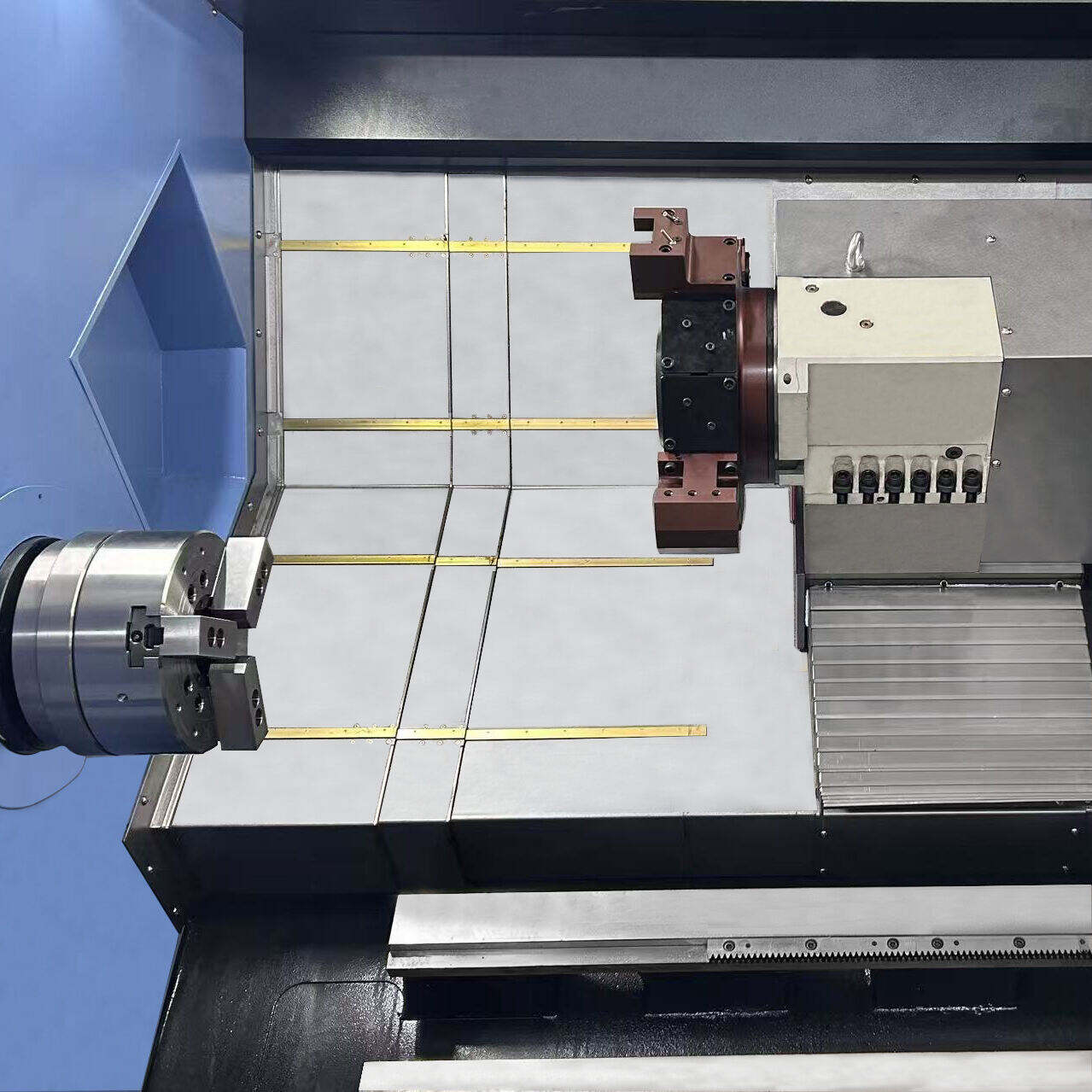

- 45 DEG Table angle

- High precision Roller linear guide

- High precision ball screw

- Imported precision bearing

- Integrated casting frame

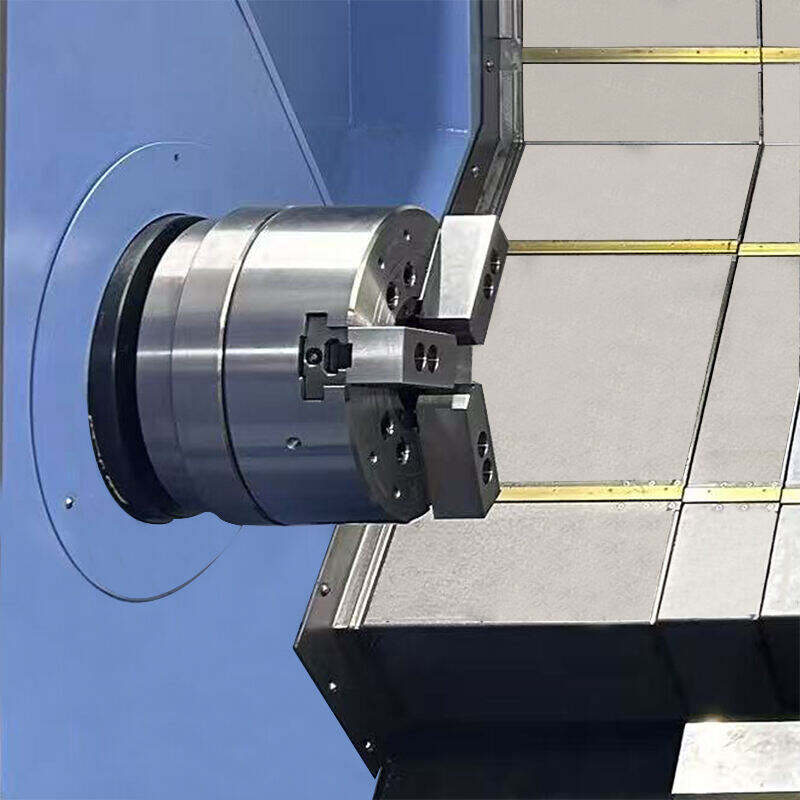

- High rigidity heavy-duty single spindle

- Hydraulic programmable tailstock

Introduction

The Precision Horizontal Turning Center from DONGS CNC is engineered to provide superior performance for high-precision metalworking and manufacturing tasks. Designed for a variety of industrial applications, this machine offers robust construction, advanced features, and ease of use, making it ideal for producing complex components with tight tolerances. The horizontal turning design allows for efficient chip removal, reducing downtime and ensuring consistent, high-quality results in high-volume production settings.

Built to handle a wide range of materials, this turning center delivers exceptional cutting performance while maintaining energy efficiency. With its user-friendly interface, advanced control systems, and durable build, it is a cost-effective solution for precision turning in demanding industries.

Key Features:

- High Precision: Features a rigid horizontal spindle and advanced CNC control system for maintaining tight tolerances and high-quality finishes.

- Heavy-Duty Construction: Built with durable, high-quality components to withstand the demands of high-volume and heavy-duty machining.

- Advanced Tooling Capability: Equipped with multiple tool stations for efficient multi-tasking and faster production cycles.

- Efficient Chip Removal: Horizontal layout ensures excellent chip flow, preventing clogs and reducing maintenance time.

- Flexible Operation: Suitable for machining a variety of materials, from metals to composite materials, offering high versatility in production.

- Enhanced Productivity: Fast setup times and rapid tool changes to minimize downtime and improve overall efficiency.

- User-Friendly CNC Interface: Intuitive, easy-to-learn controls, designed for operators of all experience levels.

Applications:

- Automotive Manufacturing: Precision turning of engine components, chassis parts, and transmission housings.

- Aerospace Industry: Machining of turbine blades, aerospace components, and structural parts for the aviation sector.

- Oil & Gas Industry: Manufacturing of parts for drilling equipment, pumps, valves, and other high-demand mechanical parts.

- Heavy Equipment Manufacturing: Turning complex components for construction machinery, industrial machines, and mining equipment.

- Medical Device Manufacturing: Precision turning of surgical tools, medical instrument components, and implants.

- Tooling and Die Production: Ideal for producing molds, dies, and high-precision tooling components.

- General Manufacturing: Versatile for producing precision metal parts across a wide range of industries, including defense, electronics, and consumer goods.

| CAPACITY | Unit | TCK800D |

| Distance between centers | mm | 1100/1600/2100/3100 |

| Chuck size | inck | 15 |

| Max. swing over bed | mm | 900 |

| Max. swing over cross slide | mm | 630 |

| Linear guide rail width | mm | 55/55 |

| TRAVELS | ||

| X-Axis Rapid Traverse | m/min | 16 |

| Z-Axis Rapid Traverse | m/min | 16 |

| X axis travel | mm | 370 |

| Z axis travel | mm | 1000/1500/2000/3000 |

| MAIN SPINDLE | ||

| Max. Spindle Speed | rpm | 2000 |

| Max. Spindle Power | kw | 30 |

| Spindle nose | - | A2-11 |

| bar capacity | mm | 91/115 |

| TURRET | ||

| No. of tool station | - | 12 |

| Turret Type | - | 12 Station live tooling(BMT65) |

| Rotary Tool | r/min | 5000 |

| tailstock | ||

| quill diameter | mm | 150 |

| quill travel | mm | 200 |

| tailstock Travel | mm | 2900 |

| tailstock taper | - | 22 |

| DIMENSIONS | ||

| Packing size | m | / |

| Width | m | / |

| Height | m | / |