Top-Quality CNC Vertical Lathe Machines for High Precision and Reliability

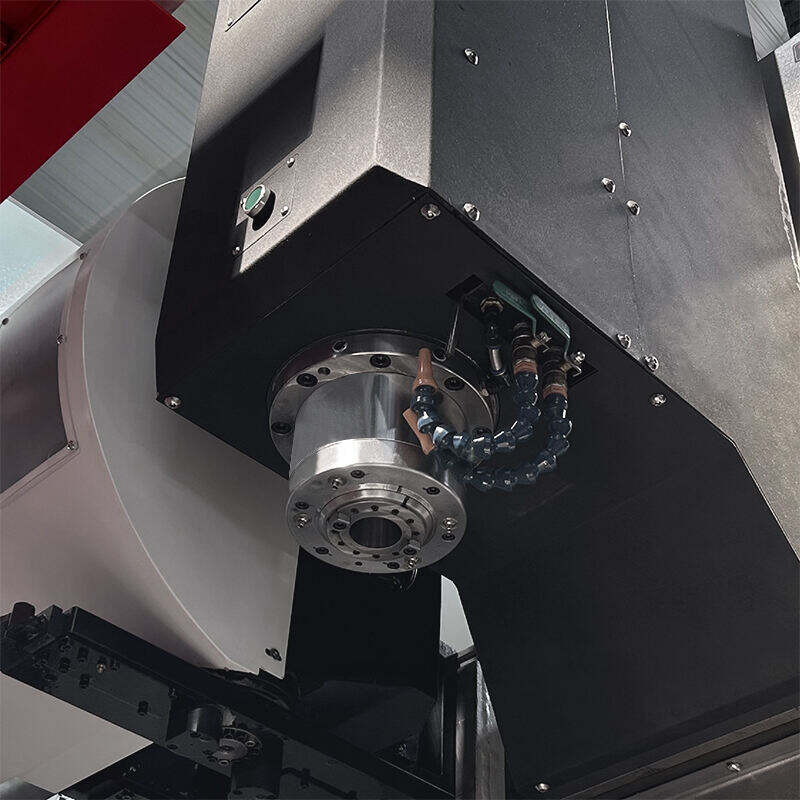

- Taiwan High precision wire rail, lead screw

- Taiwan hydraulic chuck

- Taiwan brand spindle

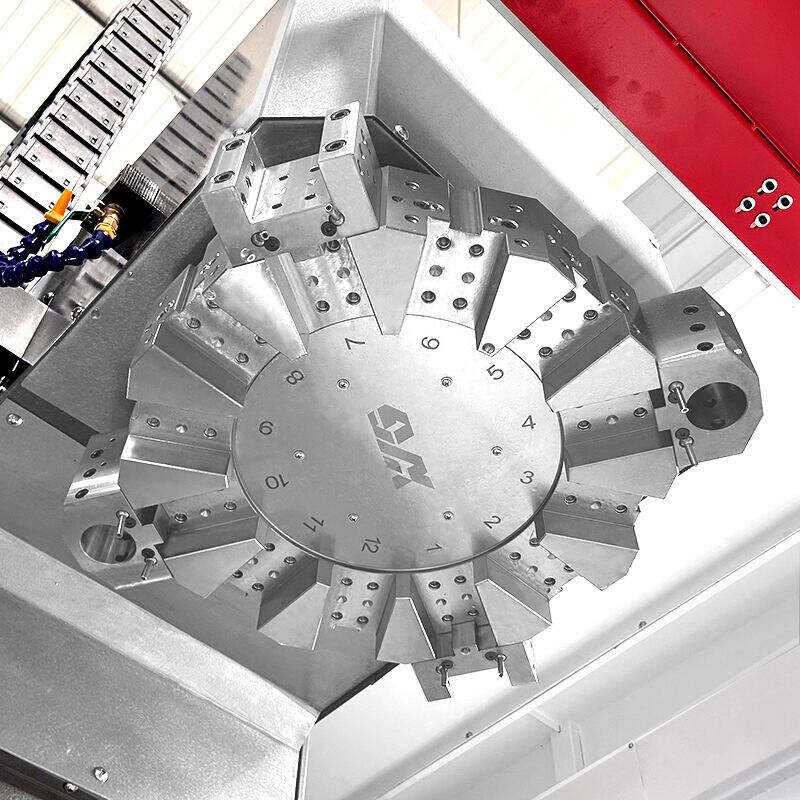

- Taiwan brand turret

- Volumetric lubrication

- Chain chip conveyor

- Three-color alarm light, foot switch, electric cabinet air conditioner

- Inner protection of lead screw wire rail

- Fully protective sheet metal cover, pneumatic sliding door

- Matching hydraulic station

- The spindle can add C axis and equipped with power turret

Introduction

The DONGS CNC Vertical Lathe is designed for high-precision and heavy-duty machining tasks, offering exceptional performance and reliability. Engineered for manufacturing large and complex metal parts, this machine is ideal for industries such as automotive, aerospace, and energy. Equipped with advanced control systems, it provides seamless automation and ensures superior surface finishes and tight tolerances. The vertical design optimizes workspace efficiency, making it the perfect solution for large-scale machining projects.

This machine supports a wide range of cutting operations including turning, boring, and milling, ensuring maximum versatility for complex component production. Whether you're working with ferrous or non-ferrous metals, the DONGS CNC Vertical Lathe delivers consistent, high-quality results that meet the demands of modern industrial manufacturing.

Key Features:

- High Precision: Features advanced CNC control systems for unparalleled accuracy in machining.

- Heavy-Duty Performance: Capable of handling large and heavy workpieces with ease.

- Versatile Machining: Supports turning, boring, milling, and other operations, ideal for diverse manufacturing needs.

- Robust Build: Built with durable materials and high-quality components to ensure long-lasting performance.

- User-Friendly Interface: Easy-to-use interface for operators, reducing setup times and increasing productivity.

- Advanced Automation: Integration with automated systems for optimized production and reduced human error.

- Energy Efficient: Designed to operate with low energy consumption, reducing overall operational costs.

- Customizable Options: Available in different sizes (VTC-850, VTC-1000, VTC-1250, VTC-1600) to fit specific project requirements.

Applications:

- Automotive Industry: Manufacturing engine components, transmission parts, and other critical automotive parts with high precision.

- Aerospace Manufacturing: Machining large turbine blades, aircraft structures, and landing gears that require high tolerance and strength.

- Heavy Equipment Manufacturing: Ideal for producing heavy-duty machine components such as gears, shafts, and housings for industrial machinery.

- Energy Sector: Precision machining of parts used in power generation equipment, such as turbines and pump housings.

- Medical Equipment Production: Creating complex and high-precision components for medical devices and implants.

- Marine Industry: Used to manufacture ship components, including propellers, rudders, and engine parts.

- Tooling and Mold Making: Essential for producing precision molds and dies for plastic injection molding and die-casting processes.