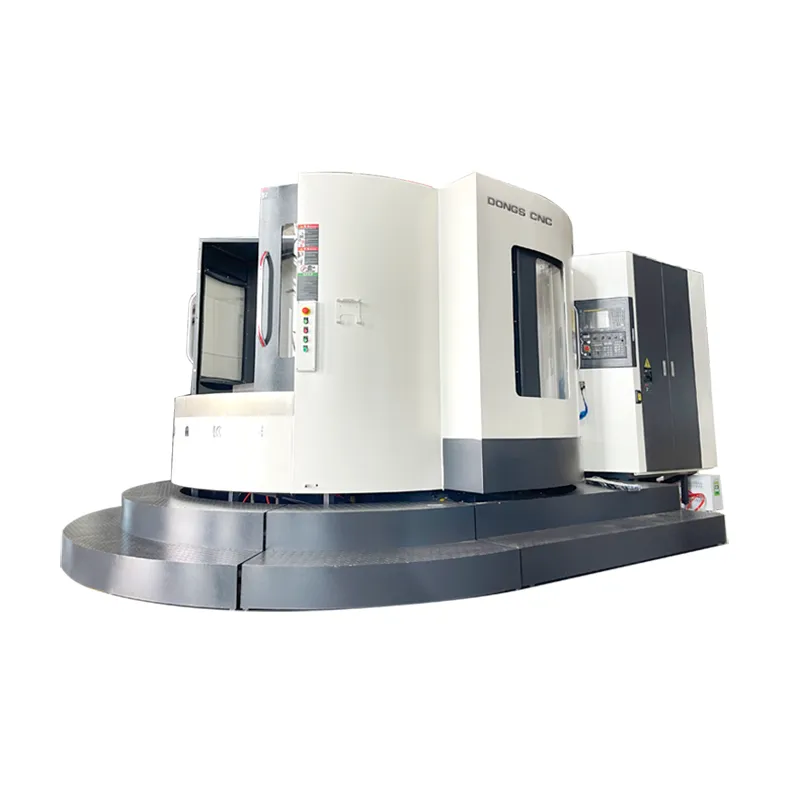

The Role of Horizontal Machining Centers in Today’s Industries

In today’s manufacturing, horizontal machining centers are critical in the high speed, and complexity in components production. These machines are made to allow for complete part manufacturing in one set-up hence cutting down on repositioning of parts and improving cycle time. Their capability to machine numerous materials such as metals, plastics, and composites, makes horizontal machining centers an essential tool for several industries. The robust nature of the machine in construction as well as the sophisticated controls guarantees uniformity as well as repeatability hence become very effective in mass and precision engineering manufacturing processes in the automobile, aerospace as well as other industries.