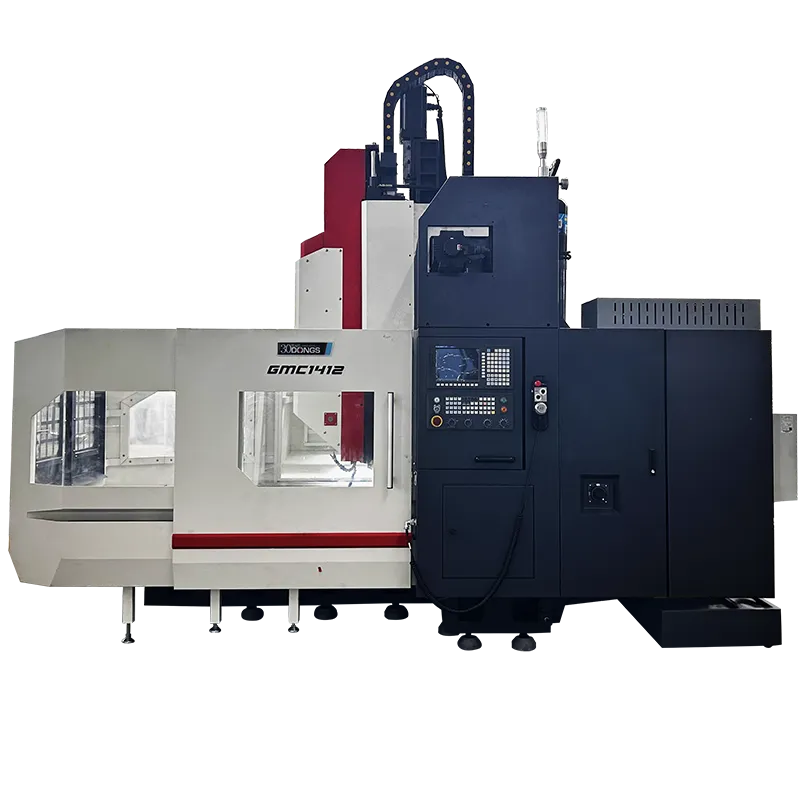

Dongs Cnc delivers exceptional precision with each gantry machining center. Designed for stability and performance, our gantry type vertical machining center ensures consistent results across demanding operations. Whether in aerospace or automotive industries, Dongs Cnc provides the accuracy professionals rely on. Each cnc gantry type machining center we manufacture is engineered for high rigidity, improving cutting precision and surface quality.