The Impact of Turning Centers on Contemporary Manufacturing

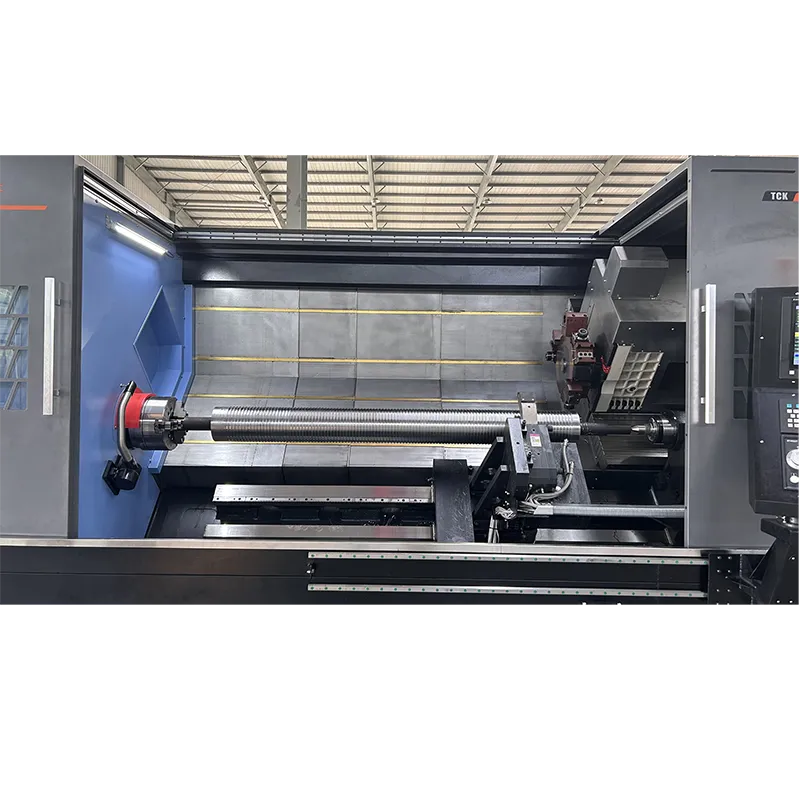

Turning centers are quite pertinent in modern-day manufacturing in that they enhance the level of precision incorporated during machining processes and completed in a reasonable period of time Turning centers are automated machines which allow for the cutting of materials in a specific shape by ensuring the material is moved in a rotary motion making it easy to manufacture components with cylindrical shapes like spindles and shafts Turning centers accept production of various materials such as metals and plastics; hence, automotive, aerospace, electronics and different industries use them a lot. Operators’ presence in production is offset through high automation of processes and brings effects efficiently. Therefore, speed is improved, and accuracy is also enhanced for the final products of the manufacturing process.