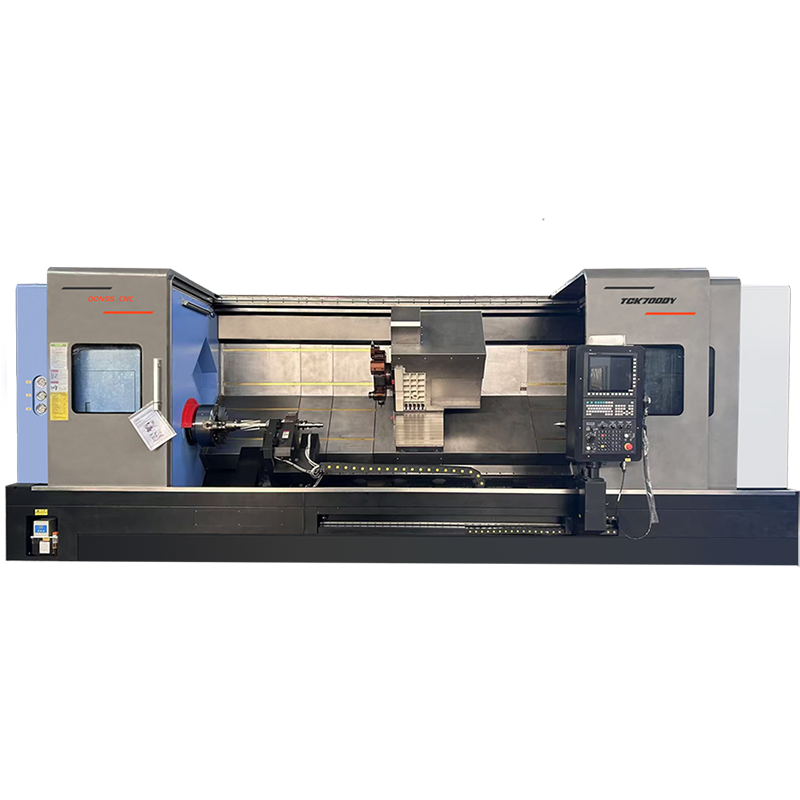

cnc machine

•45 DEG Table angle

•High precision Roller linear guide

•High precision ball screw

•Imported precision bearing

•Integrated casting frame

•High rigidity heavy-duty single spindle

•Hydraulic programmable tailstock

Introduction

1.Main structural features of CNC machine:

(1)TCK700DY is a large horizontal turning center with a 45° inclined bed, which is made of high-strength cast iron. The ribs are optimized through finite element analysis, high-strength cast iron materials, resin sand molding, sufficient secondary aging and natural aging, so that the machine tool base parts are rigid and the stability of the machine tool for long-term use is guaranteed.

(2)Both the X and Z axes use high-precision, high-load capacity and high-reliability linear rolling guides. The Z axis adopts a 6-slide design, which greatly increases the rigidity and cooperates with automatic forced lubrication to reduce the friction resistance of the feed movement, improve the accuracy and life of the machine tool; the feed speed and positioning accuracy of the machine tool are higher.

(3)The tailstock part adopts programmable control, the sleeve is an internal rotation structure, and a pin is used, which can greatly improve the stability and accuracy of cutting. The tailstock body is locked by hydraulic automatic locking, and the overall movement is standardly equipped with hydraulic automatic, and servo motor drive is optional.

(4)The spindle box is made of high-precision cast iron, with reinforcing ribs cast on the outside to enhance its robustness. The double-row roller bearing ensures the high rigidity and high efficiency of the spindle power transmission, and can demonstrate great heavy-duty cutting capabilities.

2.Main uses of CNC machine:

(1)For large pipe and shaft processing, it is suitable for complex parts processing in oil and gas pipelines, flanges, engineering machinery hydraulic parts, aviation and shipbuilding industries. The maximum turning diameter and length are 680mm and 5000mm respectively. The inclined bed design makes the operation smoother and the chip removal smoother.

(2)Only one clamping is required to realize the processing of large and complex parts. It has the largest processing range and the most powerful processing performance among similar products. Provide the best solution for processing various pipe workpieces.

(3) The CNC machine can be cut in a variety of ways (such as internal and external turning, end milling, tapping, U drilling, etc.)

| Technical specifications | unit | TCK700DY | |||

| Processing range | Maximum turning diameter on the bed | mm | Φ780 | ||

| Maximum turning diameter on the saddle | mm | Φ500 | |||

| Maximum turning diameter | mm | Φ680 | |||

| Center distance | mm | 1100/1600/2100/3100/4100/5100 | |||

| Spindle | Spindle head type | mm | A2-8 | A2-11 | |

| Spindle through hole diameter | mm | 88 | 105 | 132 | |

| Bar diameter ≤ | mm | 76 | 91 | 116 | |

| Maximum spindle speed | r/min | 3000 | 2000 | 1800 | |

| Main motor rated output | Kw | 22 | |||

| Maximum spindle output torque | NM | 573NM | |||

| Fixture | Hydraulic chuck | inch | 12/15/18/21/24 | ||

| Tailstock | Tailstock sleeve Internal rotation structure | mm | 1100/1600 MT5 2100 and above MT6 | ||

| Tailstock movement form | / | Hydraulic programmable fully automatic | |||

| Saddle | Tilt angle | DEG | 45 ° | ||

| Move distance X | mm | 350 | |||

| Move distance Z | mm | 1000/1500/2000/3000/4000/5000 | |||

| Y axis travel | mm | ±75 | |||

| Fast moving speed X/Y/Z | m/min | 16/10/16 | |||

| Servo motor X/Y/Z | KW | 2.5/1.4/2.5 | |||

| turret | Type | Servo Hydraulics | BMT65 horizontal 12 stations | ||

| Time between tool changes | S | 0.5 | |||

| Number of tool positions | / | 12 stations | |||

| Tool size (turning/boring) | mm | 32×32/Φ50 | |||

| Coller chuck model | / | ER40 | |||

| Power turret power | KW | 5.5-7.5 | |||

| Power turret speed | rpm | 4000 | |||

| Center distance | Dimensions | Net weight/gross weight (approx.) | |||

| 1000 | 4000X2300X2400mm | 7600/7900KG | |||

| 1500 | 4700X2650X2400mm | 8800/9500KG | |||

| 2000 | 5000X2600X2400mm | 9800/10500KG | |||

| 3000 | 6400X3000X2600mm | 12500/13300KG | |||

| 4000 | 7500X2750X2600mm | 14800/15800KG | |||

| 5000 | 8700X2750X2600mm | 17000/18000KG | |||

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001

certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.