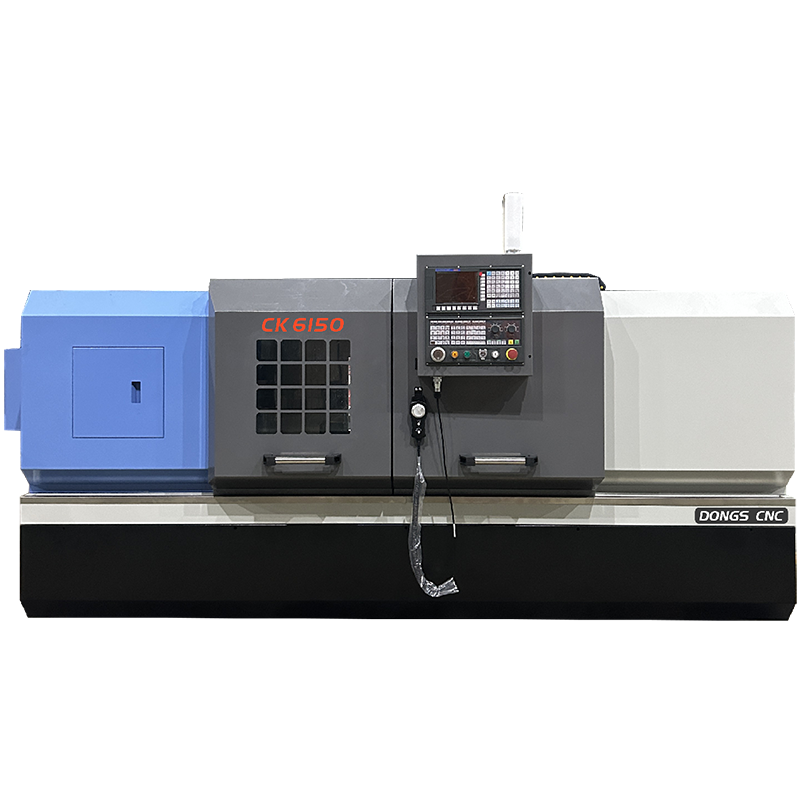

Affordable Flat Bed CNC Lathe for Versatile Industrial Applications

- Widened high stability bed

- The main shaft has three speed changes

- Variable frequency stepless in gear

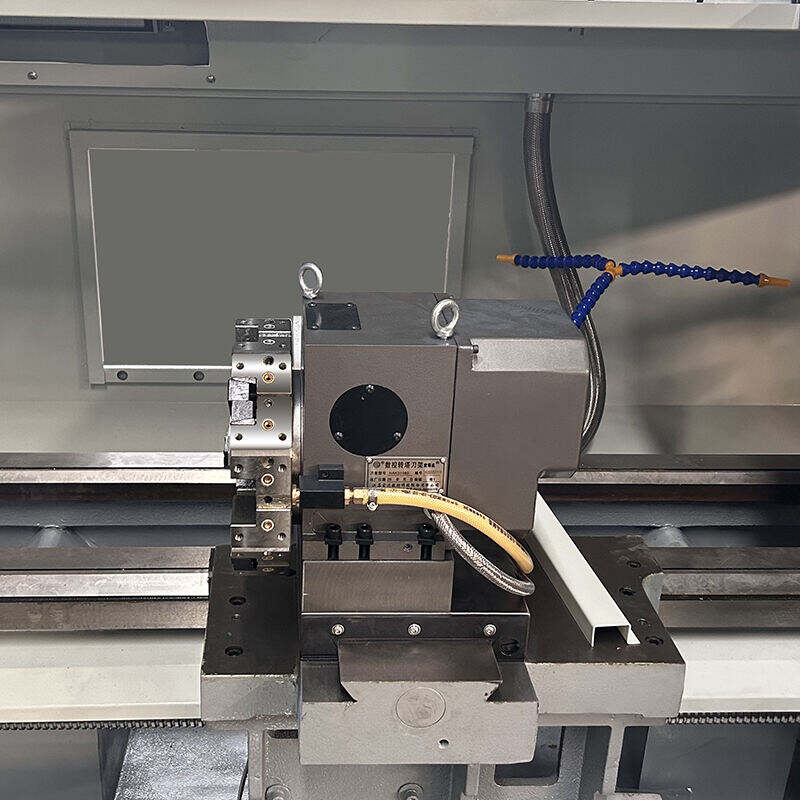

- Widened carriage

- Automatic centralized lubrication

Introduction

The DONGS CNC Flat Bed CNC Lathe offers an affordable yet highly efficient solution for a wide range of industrial applications. Designed with precision and durability in mind, this machine provides superior performance, making it ideal for turning, threading, boring, and facing various workpieces. The flat bed design ensures optimal rigidity, stability, and high accuracy, even during the most demanding machining operations.

With advanced CNC control systems, the DONGS CNC Flat Bed CNC Lathe delivers reliable and consistent results, enabling manufacturers to optimize production efficiency. Its robust construction and versatile tooling options make it suitable for both small batch production and large-scale manufacturing. Whether working with metal, plastics, or other materials, this lathe is perfect for industries requiring high-quality machining at a competitive price point.

Key Features:

- Cost-Effective Solution: Offers excellent value for money without compromising on quality or performance.

- Advanced CNC Control: Features state-of-the-art CNC technology for easy operation, superior precision, and enhanced productivity.

- Flat Bed Design: Provides improved stability and vibration damping, ensuring accurate and consistent machining results.

- High-Precision Machining: Capable of turning, threading, boring, and facing with tight tolerances and high-quality finishes.

- Rigid Construction: Built with a solid structure to handle heavy-duty cutting and long-term operations with minimal wear and tear.

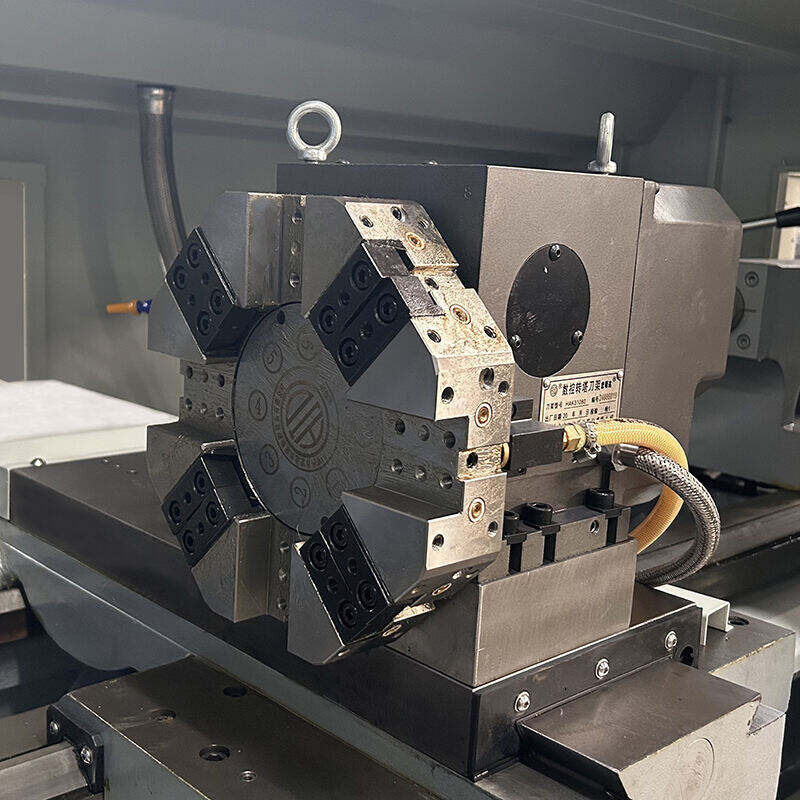

- Customizable Options: Can be tailored with various accessories like automatic tool changers, rotary tables, and more, to suit specific needs.

- User-Friendly Interface: Simplifies machine setup and operation, making it accessible to both novice and experienced operators.

- Wide Range of Machining Operations: Capable of handling various tasks, including turning, facing, and drilling with ease.

- Energy-Efficient: Designed to reduce power consumption while maintaining high-performance standards.

- Minimal Maintenance: Built for durability and reliability, with easy maintenance for long-term use.

Applications:

- Automotive Industry: Ideal for machining automotive parts like shafts, pistons, flywheels, and brake discs with high precision.

- Aerospace Manufacturing: Suitable for producing aircraft components such as turbine blades, brackets, and structural parts that require tight tolerances.

- Heavy Machinery and Equipment: Perfect for machining large and heavy components, including gears, housings, and shafts for industrial machinery.

- Metalworking and Tooling: Great for producing cutting tools, molds, and dies used in various manufacturing processes.

- Electronics Manufacturing: Used to machine parts for electrical devices, connectors, and enclosures with high accuracy.

- Construction and Engineering: Ideal for fabricating components like flanges, fittings, and valves used in the construction of infrastructure and machinery.

- Medical Equipment Production: Machining precise components for medical devices and equipment, ensuring high quality and reliability.

- Energy and Power Generation: Suitable for turning large parts like turbines, shafts, and valves for power generation systems.

| Specifications | Unit | CK6140 | CK6150 | CK6160 |

| Swing over bed | mm | ф400 | ф500 | ф600 |

| Swing over slide | mm | ф210 | ф290 | ф350 |

| Width of bed | mm | 360 | 400 | 440 |

| Max processing length | mm | 600/850 | 850/1350/1850 | 850/1350/1850/2850 |

| X axis travel | mm | X:210 | X:250 | X:330 |

| Spindle transmission type | - | Independent spindle/gear internal frequency conversion | Independent spindle/gear internal frequency conversion | Independent spindle/gear internal frequency conversion |

| Spindle speed | rpm | 32-1600/2000 | 20-1600/2000 | 20-1600/2000 |

| Spindle end | - | A2-6 | A2-8 | A2-8 |

| Diameter of spindle through hole | mm | Φ65 | Φ82 | ф82/105 |

| Spindle motor | kw | 5.5 | 7.5 | 11 |

| X/Z Rapid traverse | m/min | 6/8 | 6/8 | 6/8 |

| X/Z axis repeatability | mm | ±0.005 | ±0.005 | ±0.005 |

| Processing accuracy | - | IT6-IT7 | IT6-IT7 | IT6-IT7 |

| Workpiece surface roughness | - | Ra1.6 | Ra1.6 | Ra1.6 |

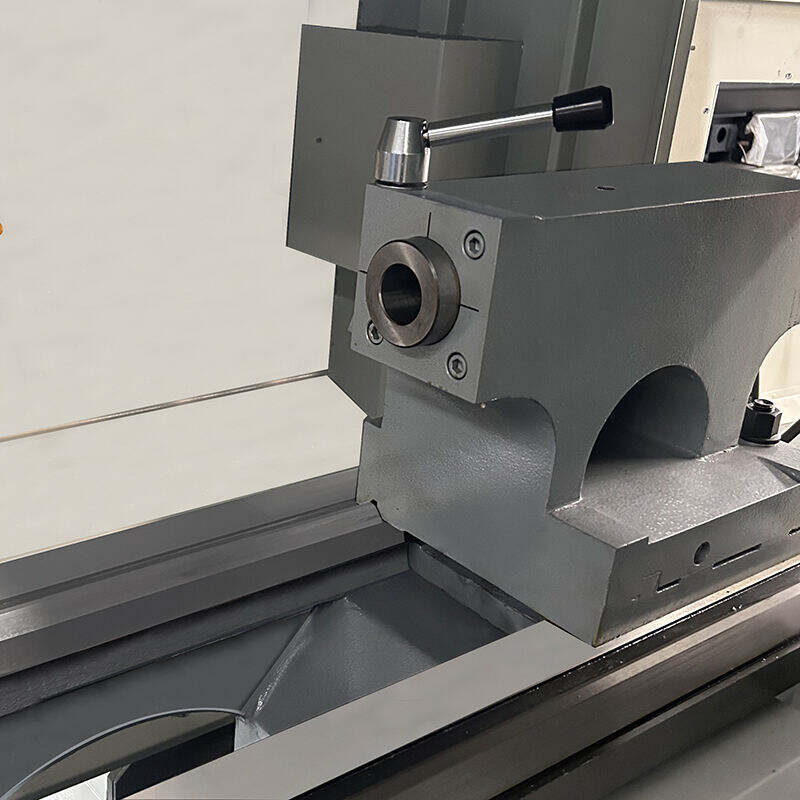

| Tailstock sleeve dia. | mm | Φ65 | Φ75 | ф75 |

| Quill traverse | mm | 130 | 140 | 150 |

| Sleeve taper | MT | MT4 | MT5 | MT5 |

| Tool post form | - | Electric 4-station/6 (8) station turret | ||

| Cutting tool shape size | mm | 20x20 | 25×25 | 25x25/32x32 |

| Machine dimension(LxWxH) | m | 2.5×1.42×1.66 | 2.8×1.7×1.8 | 3.1x1.8x1.85 |

| Net.weighe(approx) | t | 1.7/1.9 | 2.6/3.2 | 3.1/3.6/4.0/4.5 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.