cnc machine tools

- High precision Roller linear guide

- High precision ball screw

- lmported precision bearing

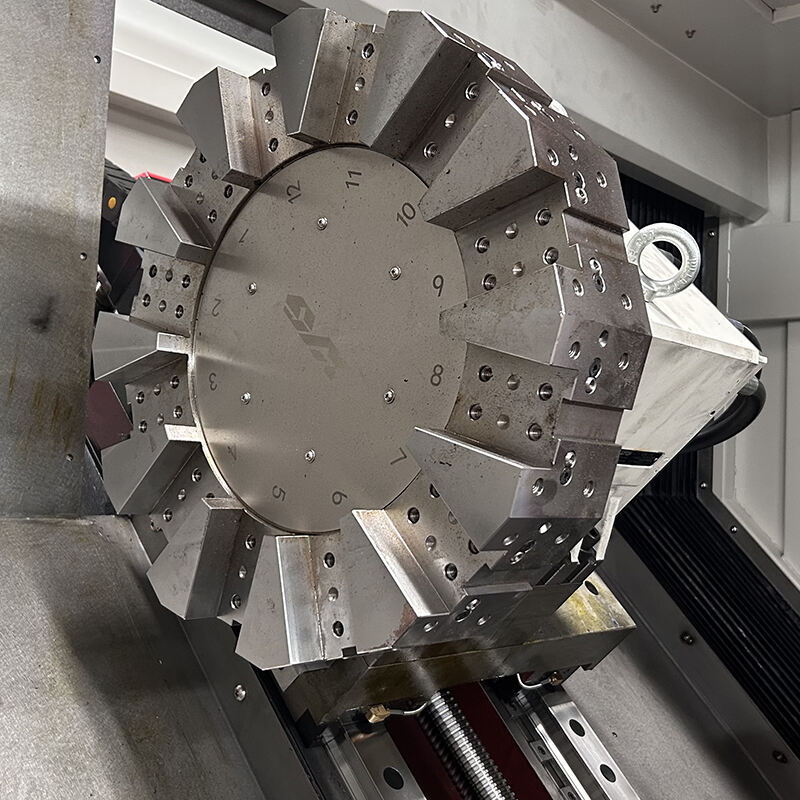

- Servo hydraulic turret

- Optional 12 Station live tooling

- Tool setting instrument is optional

- Main shaft synchronous belt drive

Introduction

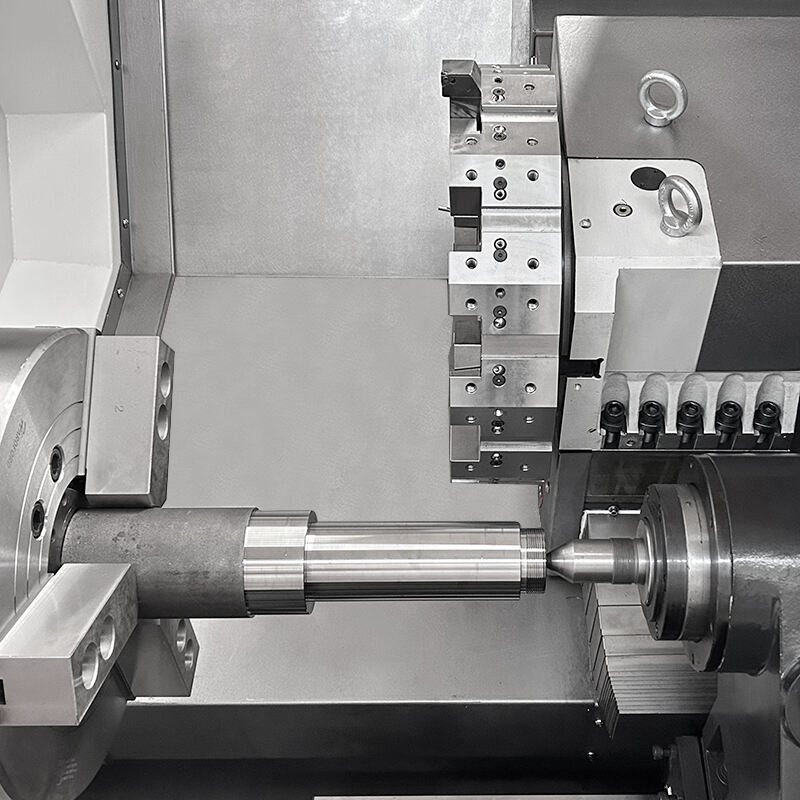

The bed of TCK700 series CNC machine tools is inclined at 45 degrees. The bed is made of one-piece high-strength cast iron, which makes the basic conditions of the machine tool have high rigidity and ensures the stability of the machine tool in long-term use.

Main features of CNC machine tools:

Space saving: 45-degree inclined bed makes better use of the manufacturer's space.

High efficiency: Optimized for fast and precise processing of small batches, shortening the processing period and improving efficiency

Advanced control system: Easy to operate and can achieve accurate part programming.

Inclined bed design: Easy to cut and remove chips, which can help extend tool life for continuous work.

Versatile: Suitable for processing a variety of materials, providing high precision and repeatability for simple and complex parts.

Main applications of CNC machine tools:

Low-Volume Manufacturing: For businesses that need flexible, low-volume production.

Prototyping and R&D: Ideal for creating prototypes or testing new designs with high precision.

Precision Machining: Used in industries that require tight tolerances, such as automotive, aerospace, and medical device manufacturing.

Tooling: Manufacturing custom tools, jigs, and fixtures.

Electronics: Precision machining of small parts used in consumer electronics, connectors, and assemblies.

Automotive Parts: Producing engine parts, chassis components, specialized machine parts.

Small Parts Manufacturing: Applications for a variety of industries, including toolmakers and engineers.

| Technical specifications | unit | TCK700 | |||

| Processing range | Maximum turning diameter on the bed | mm | Φ780 | ||

| Maximum turning diameter on the saddle | mm | Φ500 | |||

| Maximum turning diameter | mm | Φ680 | |||

| Center distance | mm | 1100/1600/2100/3100/4100/5100 | |||

| Spindle | Spindle head type | mm | A2-8 | A2-11 | |

| Spindle through hole diameter | mm | 88 | 105 | 132 | |

| Bar diameter ≤ | mm | 76 | 91 | 116 | |

| Maximum spindle speed | r/min | 3000 | 2000 | 1800 | |

| Main motor rated output | Kw | 30 | |||

| Maximum spindle output torque | NM | 573NM | |||

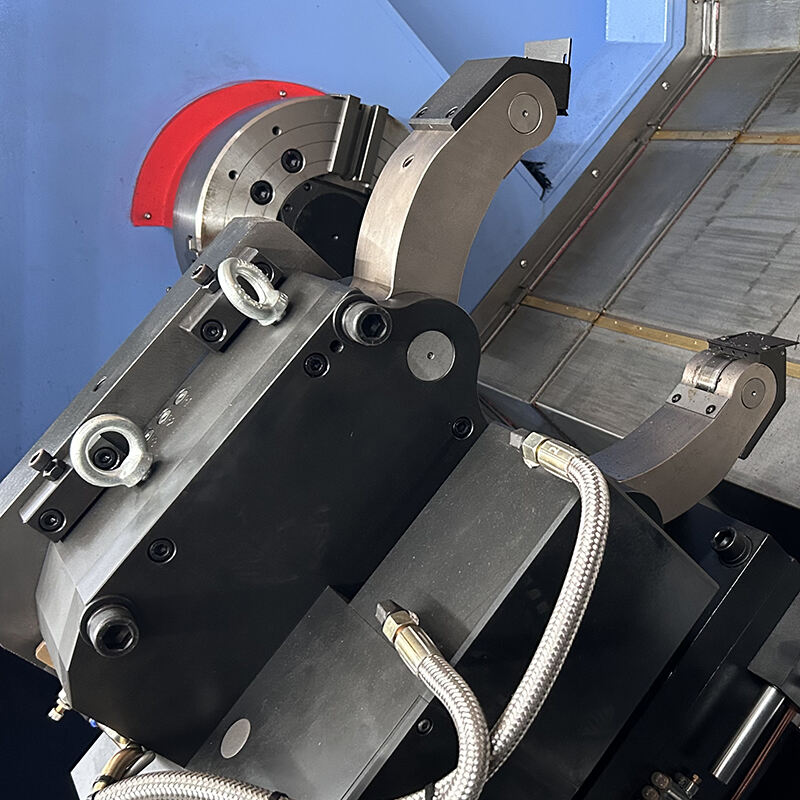

| Fixture | Hydraulic chuck | inch | 12/15/18/21 | ||

| Tailstock | Tailstock sleeve Internal rotation structure | mm | 1100/1600 MT5 2100 and above MT6 | ||

| Tailstock movement form | / | Hydraulic programmable fully automatic | |||

| Saddle | Tilt angle | DEG | 45 ° | ||

| Move distance X | mm | 350 | |||

| Move distance Z | mm | 1000/1500/2000/3000/4000/5000 | |||

| Fast moving speed X/Z | m/min | 16/16 | |||

| Servo motor X/Z | KW | 2.5/2.5 | |||

| turret | Type | Servo Hydraulics | 12-station servo hydraulic turret | ||

| Time between tool changes | S | 0.5 | |||

| Number of tool positions | / | 12 stations | |||

| Tool head diameter | mm | 480 | |||

| Tool size (turning/boring) | mm | 32×32/Φ50 | |||

| Center distance | Dimensions | Net weight/gross weight (approx.) | |||

| 1000 | 4000X2300X2400mm | 7600/7900KG | |||

| 1500 | 4700X2650X2400mm | 8800/9500KG | |||

| 2000 | 5000X2600X2400mm | 9800/10500KG | |||

| 3000 | 6400X3000X2600mm | 12500/13300KG | |||

| 4000 | 7500X2750X2600mm | 14800/15800KG | |||

| 5000 | 8700X2750X2600mm | 17000/18000KG | |||

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.