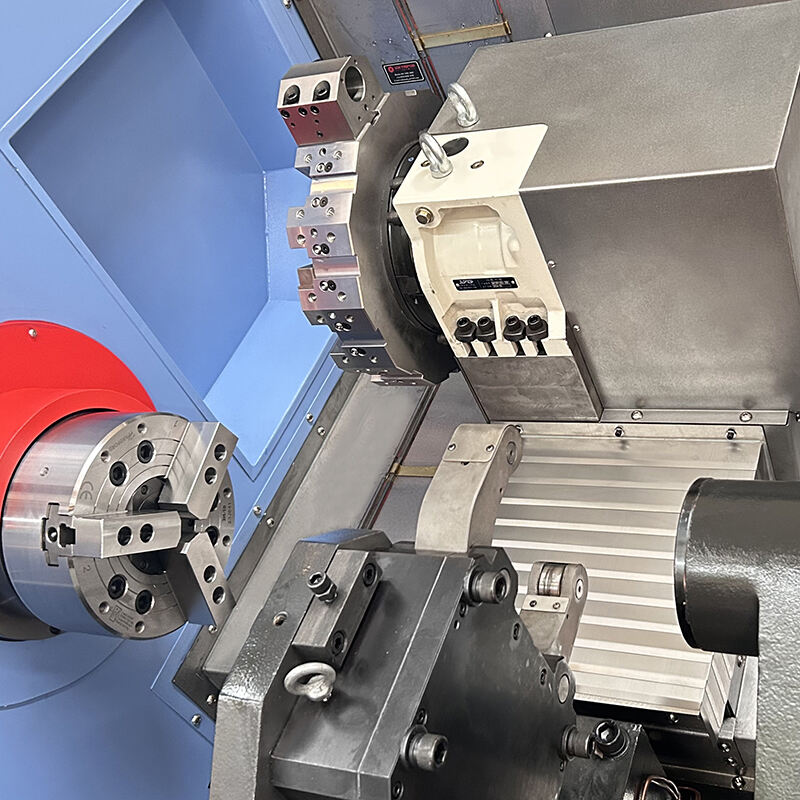

cnc metal lathe

- High precision Roller linear guide

- High precision ball screw

- lmported precision bearing

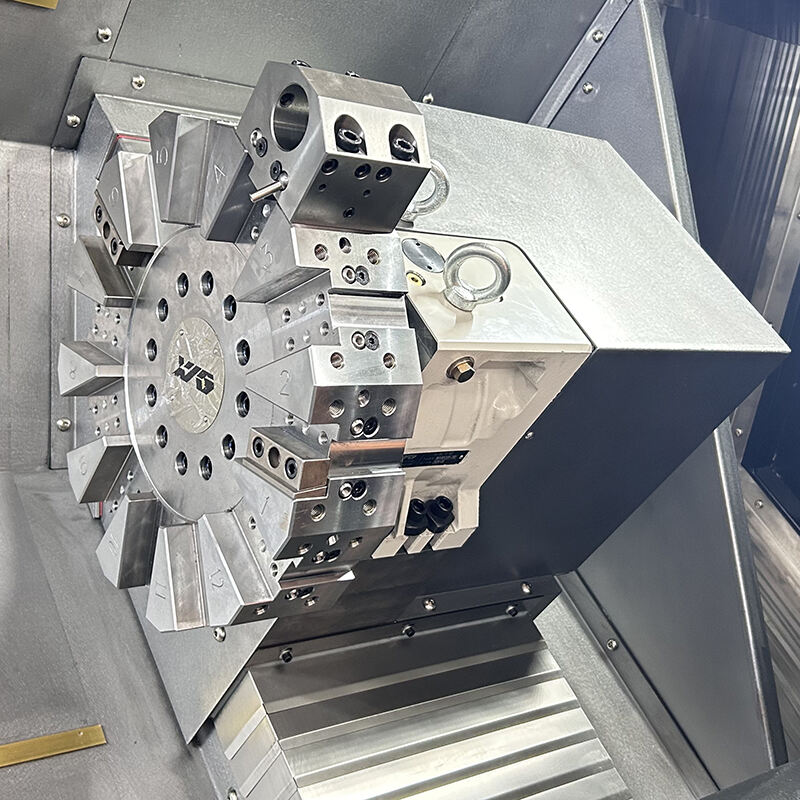

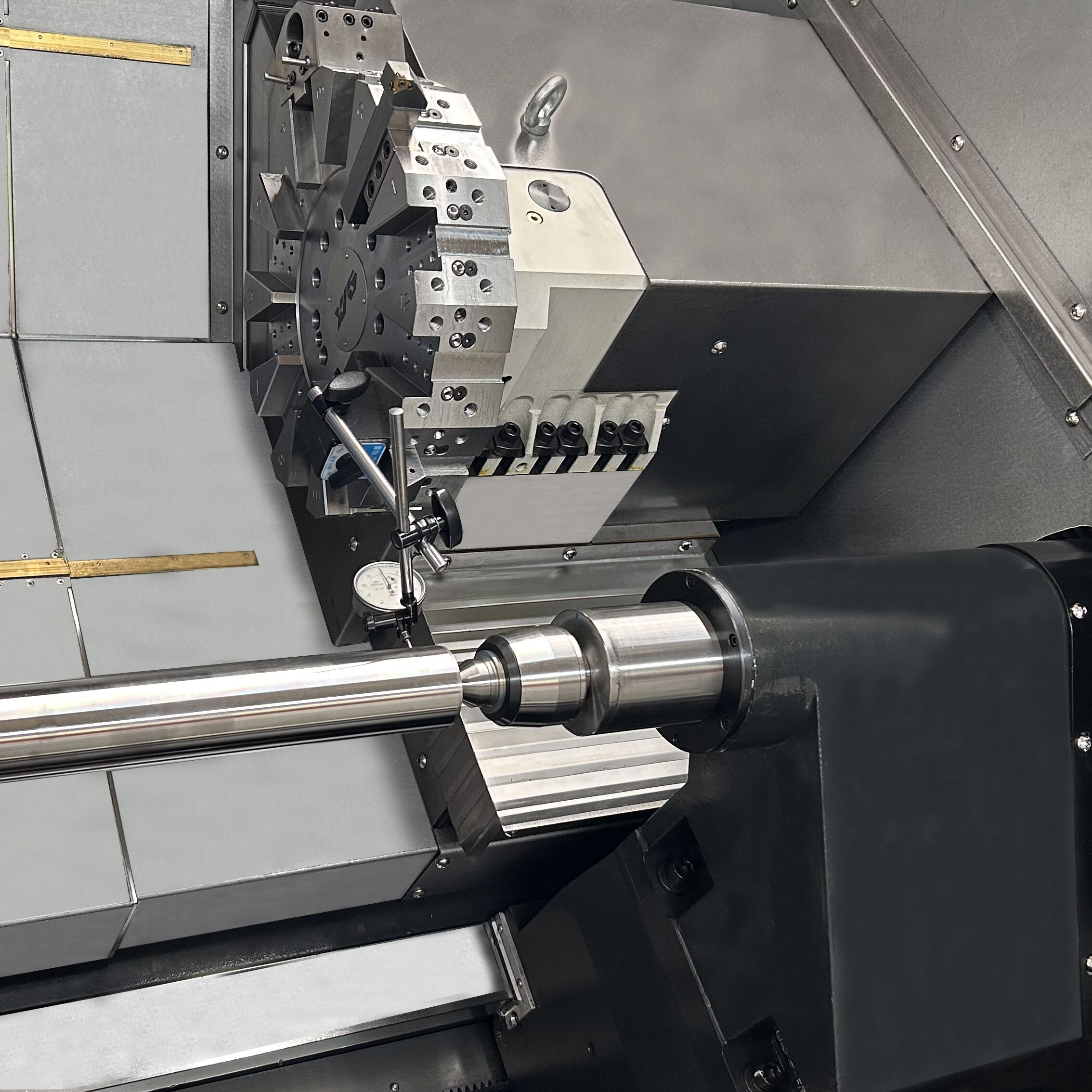

- Servo hydraulic turret

- 12 Station live tooling

- Tool setting instrument is optional

- Main shaft synchronous belt drive

Introduction

Main features of CNC metal lathe

1. TCK600 SeriesThe 45° inclined bed and base are integrally cast and formed with high-strength cast iron. The finite element analysis optimizes the arrangement of reinforcement ribs, high-strength cast iron materials, resin sand molding, and sufficient secondary aging and natural aging, so that the basic parts of the machine tool have high rigidity and ensure the stability of the machine tool for long-term use; with automatic forced lubrication, the friction resistance of the feed movement is greatly reduced, and the machine tool accuracy and life are improved.

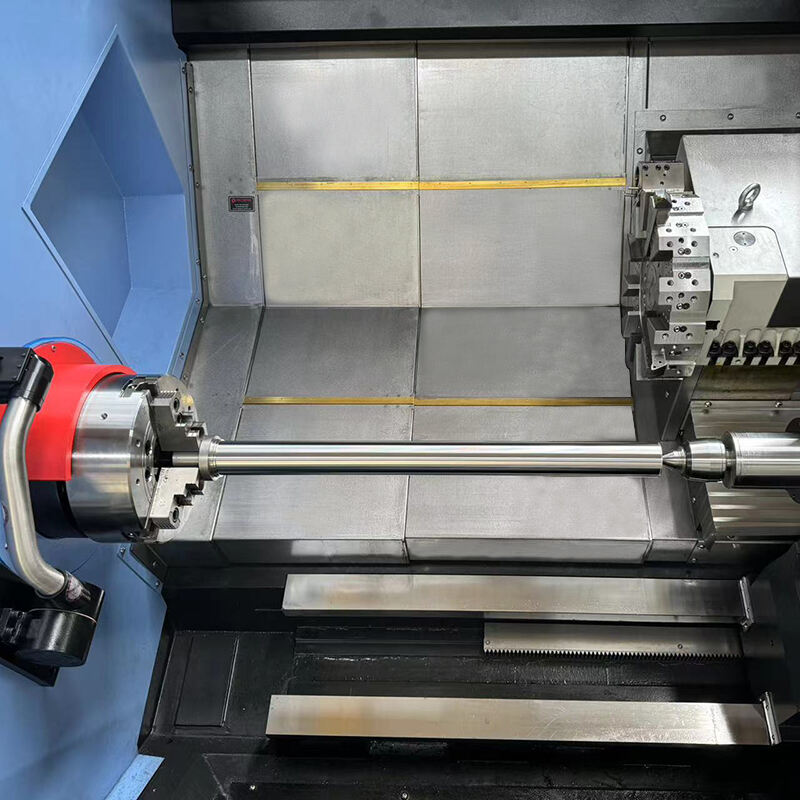

The overall movement of the tailstock is standardly equipped with hydraulic automatic, and servo motor drive is optional.

2. Both the X and Z axes use high-precision, high-load capacity, and high-reliability linear rolling guides, with automatic forced lubrication, to reduce the friction resistance of the feed movement, improve the accuracy and life of the machine tool; the feed speed and positioning accuracy of the machine tool are higher.

3. The spindle adopts a combination of large-diameter precision angular contact ball bearings with four in front and two in the back, or a combination of large-diameter precision angular contact thrust ball bearings and double-row cylindrical roller bearings. The spindle servo motor drives the spindle with a transmission ratio of 1:2, which has excellent rigidity and high torque at low speed.

4. The electrical unit cabinet of the machine tool has good sealing performance and is equipped with an electrical cabinet air conditioner to ensure that the CNC system works normally under high temperature and high humidity environment.

5. A side-mounted chain plate chip conveyor is used. The operation of the chip conveyor is programmable and the chip conveyor is installed by pushing it in from the front of the machine tool, which is easy to adjust.

In addition, the chip conveyor can be equipped with an oil-water separation mechanism, which can separate the lubricating oil in the cutting fluid, reduce the generation of oil mist, enhance the cooling effect of the coolant on the tool, and extend the service life of the tool.

(1) The machine tool is equipped with a water gun to clean iron chips.

(2) The chip conveyor is reasonably arranged and does not interfere with the bed of the machine tool.

6. Hydraulic system

The hydraulic system uses Taiwanese hydraulic components; the oil tank is fixed on the back of the bed, and each valve group and the corresponding pressure gauge are installed on the left and right front covers of the machine tool to facilitate the observation and adjustment of the pressure of each working circuit.

7. The machine tool pays attention to the design of edge technology and has reliable protection. When strong cutting and high-pressure spraying of coolant are performed, there is no splash of iron chips or coolant leaking out of the machine tool.

8. The clamping and loosening of the hydraulic chuck can be controlled by foot, which is convenient and fast.

9. The machine tool has a novel appearance design and convenient panel operation. Combining its high power, high precision, high performance and other characteristics, this series of machine tools is undoubtedly the most powerful product among similar models.

Main applications of CNC metal lathe:

Metalworking: Suitable for turning, forming and cutting a wide range of metals, including steel, aluminum and titanium.

Automotive Industry: Precision machining of engine parts, transmission components and other metal parts.

Aerospace Manufacturing: Used to produce high-precision parts for aircraft and spacecraft.

General Manufacturing: Suitable for producing parts used in machinery, tools and other industrial applications.

Prototype Development: Ideal for creating prototypes due to its flexibility to handle both small and large batches.

Medical Device Manufacturing: Precision turning is used to manufacture components used in medical devices and instruments.

| Technical specifications | unit | TCK600 | ||

| Processing range | Maximum rotation diameter on the bed | mm | Φ630 | |

| Maximum rotation diameter on the saddle | mm | Φ450 | ||

| Maximum machining diameter | mm | Φ600 | ||

| Center distance | mm | 1100/1600 | ||

| Spindle | Spindle head type | mm | A2-8 | |

| Spindle through hole diameter | mm | 86 | 105 | |

| Bar diameter < | mm | 74 | 91 | |

| Maximum spindle speed | r/min | 3000 | 2000 | |

| Main motor rated output | Kw | 15 | ||

| Fixture | Hydraulic chuck | inch | 10/12 | |

| Tailstock | Tailstock sleeve | mm | MT5 | |

| Tailstock movement form | / | Hydraulic automatic programmable | ||

| Tailstock travel | mm | 1100/1600 | ||

| Tailstock guide form | / | Hard rail | ||

| Saddle | Tilt angle | DEG | 45 ° | |

| Move distance X | mm | 310 | ||

| Move distance Z | mm | 1100/1600 | ||

| Fast moving speed X/Z | m/min | 24/24 | ||

| Servo motor X/Z | KW | 2.5/2.5 | ||

| turret | Turret type | / | Cutter diameter 420 | |

| Time between tool changes | S | 0.5 | ||

| Number of tool positions | / | 12 stations | ||

| Tool size (turning/boring) | mm | 25×25 Φ40 | ||

| Center distance | Dimensions | Weight (approx.) | ||

| 1100 | 4200X2100X2300mm | 6200KG | ||

| 1600 | 4700X2100X2300mm | 7200KG | ||

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.