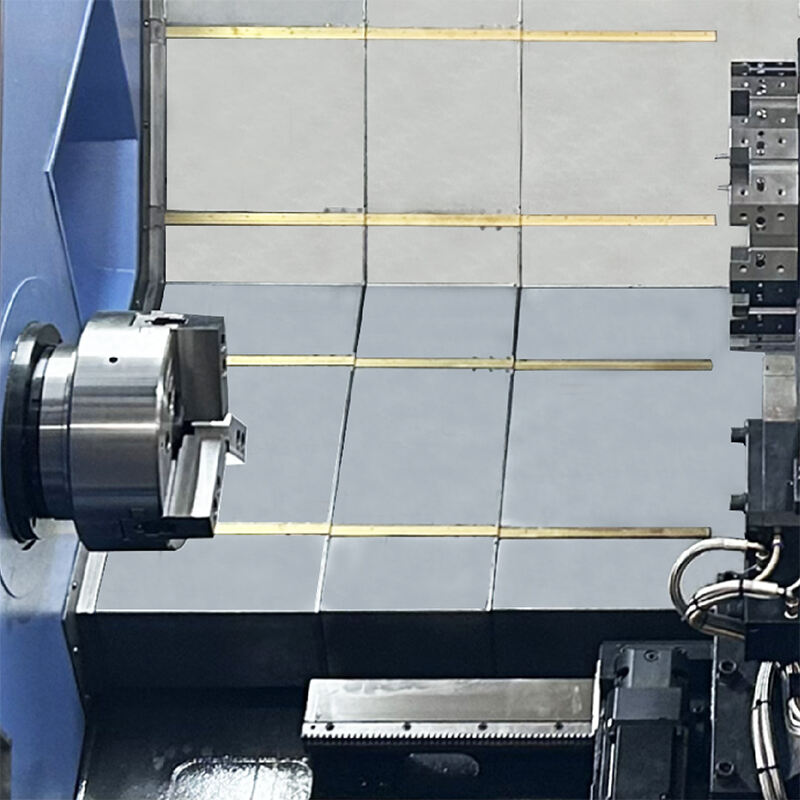

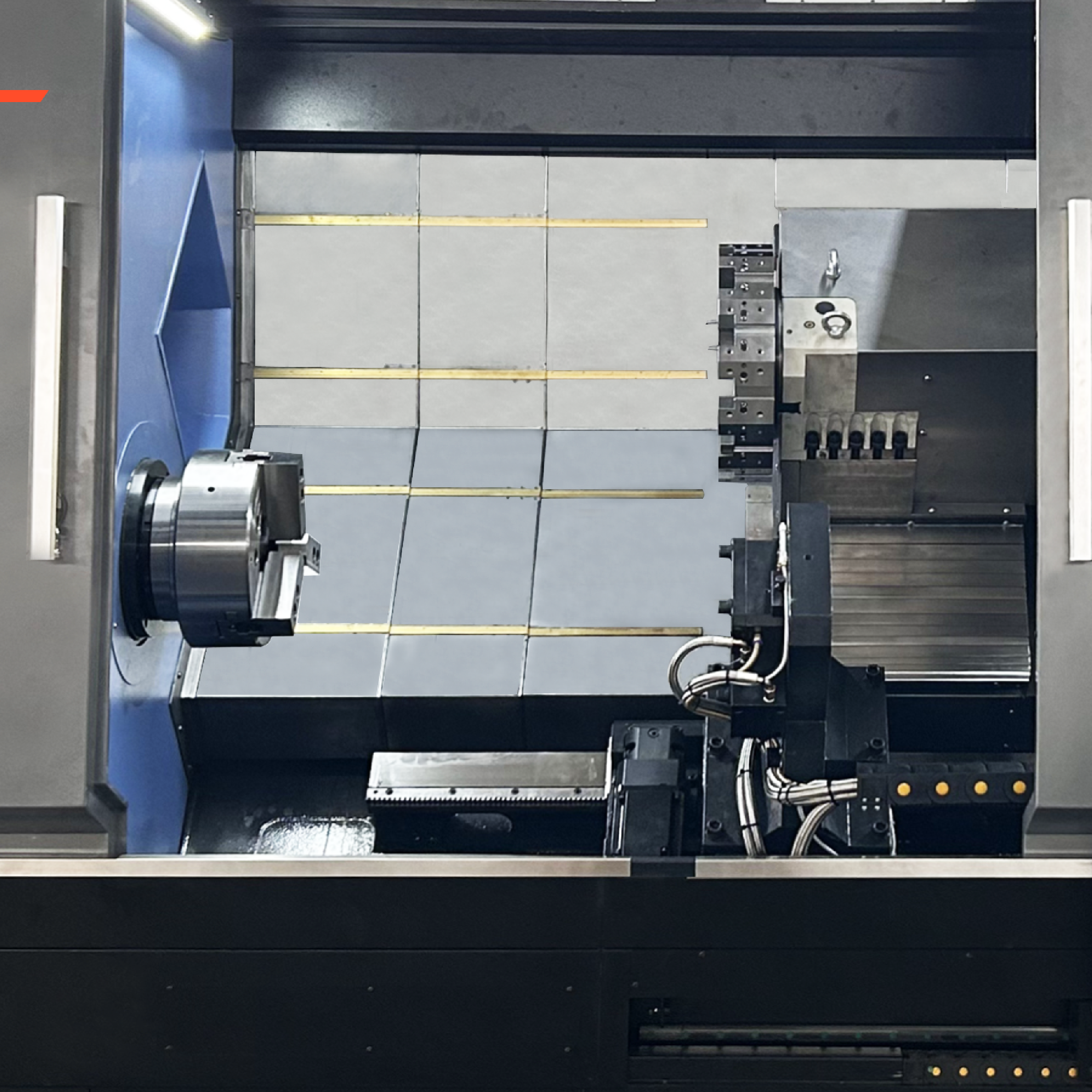

cnc turning machine

- High precision Roller linear guide

- High precision ball screw

- lmported precision bearing

- Servo hydraulic turret

- Optional 12 Station live tooling

- Tool setting instrument is optional

- Main shaft synchronous belt drive

Introduction

Main features of CNC turning machine:

1.The TCK800 CNC turning machining series adopts a 45-degree integral cast inclined bed structure, which is manufactured using high-strength cast iron and resin sand molding technology. The finite element analysis optimizes the rib layout, and combined with double aging treatment (artificial aging and natural aging), the structural strength of the basic components is significantly improved, ensuring that the equipment maintains excellent stability in long-term use.

2. The motion system adopts high-precision linear roller guides, and both the X/Z axes have excellent load-bearing performance and operational reliability. The Z axis innovatively applies a six-slide layout, combined with an automatic pressure lubrication device, which effectively improves the structural rigidity and reduces friction loss, achieving higher positioning accuracy, faster feed rate and longer service life.

3. The intelligent tailstock system is equipped with a programmable control module, and the innovative internal rotating sleeve structure is combined with a fixed center design to improve cutting accuracy. The hydraulic automatic locking mechanism is used to achieve rapid positioning, the hydraulic drive system is standard, and the servo motor drive solution can be optionally used to achieve precise movement control

4.The spindle system adopts a composite bearing configuration solution: a combination of large-diameter precision angular contact thrust ball bearings and double-row cylindrical roller bearings, coupled with a high-power and high-torque servo motor drive. A low-speed, high-torque output system with excellent rigidity coefficient is formed.

Main application areas of CNC turning machine

Custom Manufacturing: Ideal for companies that need specialized parts or high-precision products.

Prototyping and Low-Volume Production: Ideal for businesses that need to create prototypes or produce small quantities of custom parts.

Automotive Industry: Precision machining of automotive parts such as engine components, gears, shafts, etc.

Aerospace Manufacturing: High-precision production of aerospace parts, including turbine blades, brackets, and housings.

Medical Device Production: Used to manufacture high-precision medical components and equipment.

Tools and Fixtures: Ideal for creating custom tools, fixtures, and clamps for a variety of production processes.

General Machining: Versatile and can complete common machining tasks in metalworking, including turning, drilling, and finishing.

| Technical specifications | unit | TCK800 | |||

| Processing range | Maximum turning diameter on the bed | mm | Φ850 | ||

| Maximum turning diameter on the saddle | mm | Φ630 | |||

| Maximum turning diameter | mm | Φ650 | |||

| Center distance | mm | 1000/1500/2000/3000/4000/5000 | |||

| Spindle | Spindle head type | mm | A2-11 | A2-15 | |

| Spindle through hole diameter | mm | 132 | 181 | 220 | |

| Bar diameter ≤ | mm | 116 | 181 | 220 | |

| Maximum spindle speed | r/min | 1800 | 1600 | 1200 | |

| Main motor rated output | Kw | 30 | |||

| Maximum spindle output torque | NM | 573NM | |||

| Fixture | Hydraulic chuck | 寸 | 12/15/18/21/24 | ||

| Tailstock | Tailstock sleeve Internal rotation structure | mm | 1000/1500 MT5 2000 and above MT6 | ||

| Tailstock movement form | / | Hydraulic programmable fully automatic | |||

| Saddle | Tilt angle | DEG | 45 ° | ||

| Move distance X | mm | 350 | |||

| Move distance Z | mm | 1000/1500/2000/3000/4000/5000 | |||

| Fast moving speed X/Z | m/min | 16/16 | |||

| Servo motor X/Z | KW | 5.9/5.9 | |||

| turret | Type | Servo Hydraulics | 12-station servo hydraulic turret | ||

| Time between tool changes | S | 0.5 | |||

| Number of tool positions | / | 12-station servo hydraulic turret | |||

| Tool head diameter | mm | 480 | |||

| Tool size (turning/boring) | mm | 32×32/Φ50 | |||

| Center distance | Dimensions | Net weight/gross weight | |||

| 1000 | 4000X2300X2400mm | 7600/7900KG | |||

| 1500 | 4700X2650X2400mm | 8800/9500KG | |||

| 2000 | 5000X2600X2400mm | 9800/10500KG | |||

| 3000 | 6400X3000X2600mm | 12500/13300KG | |||

| 4000 | 7500X2750X2600mm | 14800/15800KG | |||

| 5000 | 8700X2750X2600mm | 17000/18000KG | |||

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.