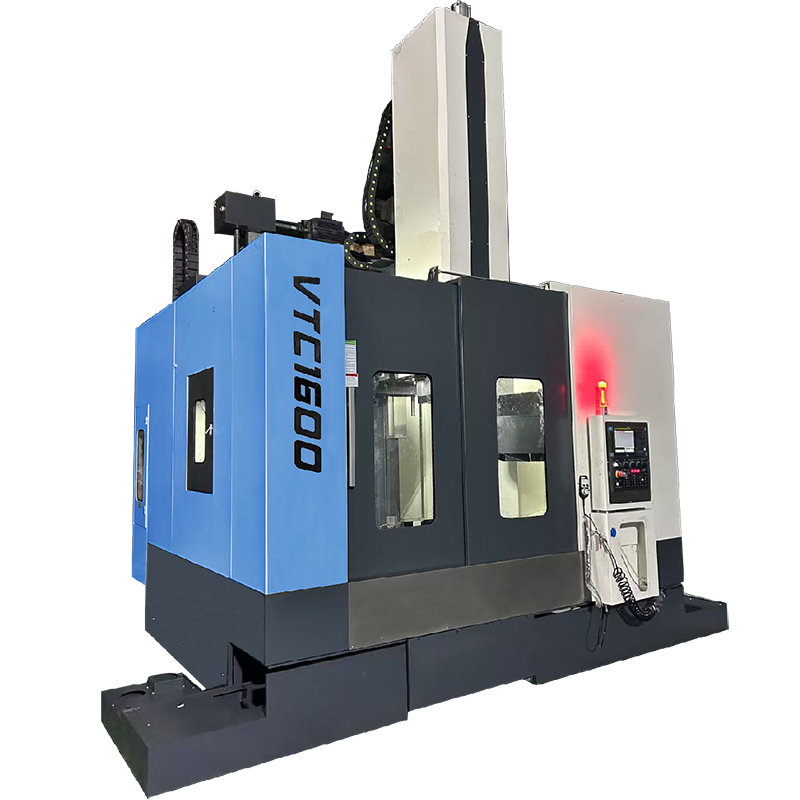

CNC Vertical Turning Center

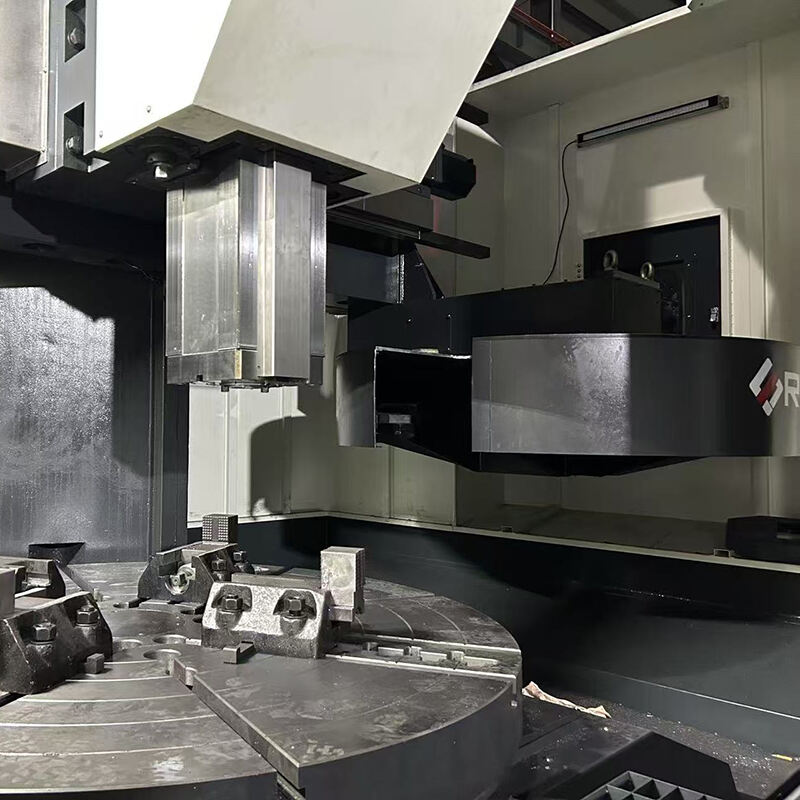

- Taiwan High precision wire rail, lead screw

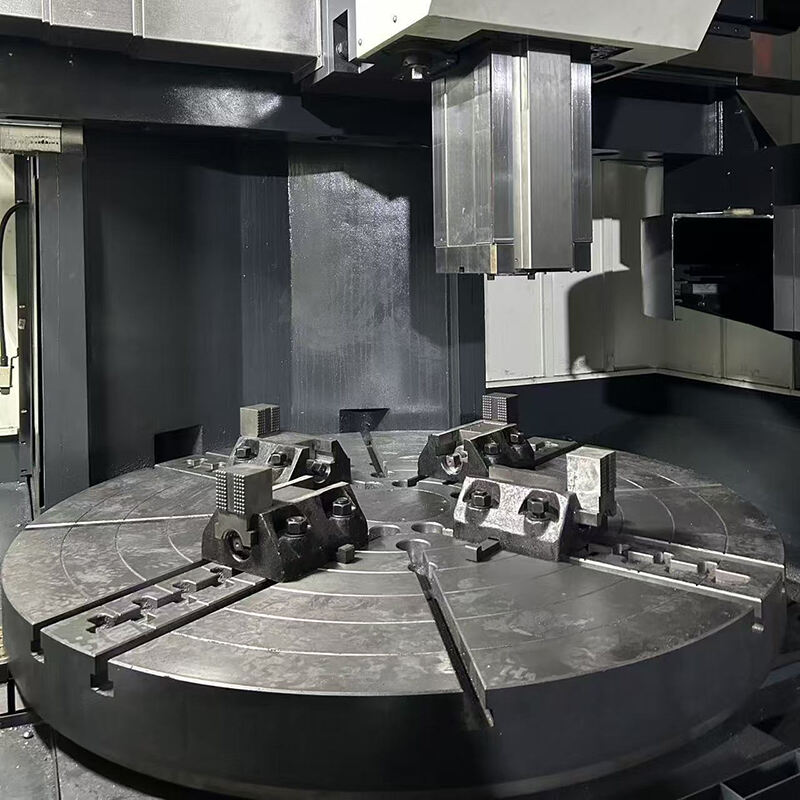

- Taiwan hydraulic chuck

- Taiwan brand spindle

- Taiwan brand turret

- Volumetric lubrication

- Chain chip conveyor

- Three-color alarm light, foot switch, electric cabinet air conditioner

- Inner protection of lead screw wire rail

- Fully protective sheet metal cover, pneumatic sliding door

- Matching hydraulic station

- The spindle can add C axis and equipped with power turret

Introduction

The main features of vertical CNC lathe:

Type A is a combination of wire gauge and hard rail machine tools, which has the advantages of both wire gauge and hard rail machine tools; Type B is a hard rail machine tool. T represents T-type ram, which can be equipped with an 8-degree inclined turret, and F represents square ram, which is suitable for deep hole processing

Main applications of vertical CNC lathes:

Large/heavy parts processing: wind power bearing seats, ship engine parts, large flanges, engineering machinery slewing bearings, etc.

Disc and ring parts: automobile wheel hubs, gear blanks, brake discs, bearing end covers, compressor housings, etc.

High-precision complex parts: aerospace engine blade bases, optical lens barrels, high-precision valve bodies, etc.

Mass production scenarios: automotive parts production lines, standardized production of hydraulic components.

Special material processing: high-temperature alloys (such as titanium alloys, nickel-based alloys), ceramic-based composites, cemented carbide, etc.

| Specifications | unit | VTC1200 | VTC1600 |

| Maximum rotation diameter of workpiece | mm | 1400 | 1600 |

| Maximum machining diameter | mm | 1250 | 1600 |

| Table diameter | mm | 1000 | 1400 |

| Spindle speed | rpm | 5-400 | 2.5-315 |

| Spindle output torque | Nm | 8000 | 12500 |

| Feed rate | mm/min | 0.1-5000 | 0.1-5000 |

| X-axis travel of tool holder | mm | 50/650 | 50/1000 |

| Z-axis travel of tool holder | mm | 650 | 650 |

| X/ZLinear guide rai | mm | 55/45roller | 55/45roller |

| X/Z-axis fast moving speed | mm/min | 15/12 | 15/12 |

| Specification of knife holder | mm | 320 | 320 |

| Main motor power | kw | 22/30 | 22/30 |

| X/Z Power offeed motor | kw | 3.5/4.7 | 4.7/4.7 |

| X/Z lead screw diameter | mm | 63 | 63 |

| Crossbeam lift stroke | mm | 700 | 700 |

| Outline dimension of machine tool | m | 3.8x2.8x3.5 | 4.2x3x3.5 |

| Overall weight (about) | t | 13.8 | 16.5 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.