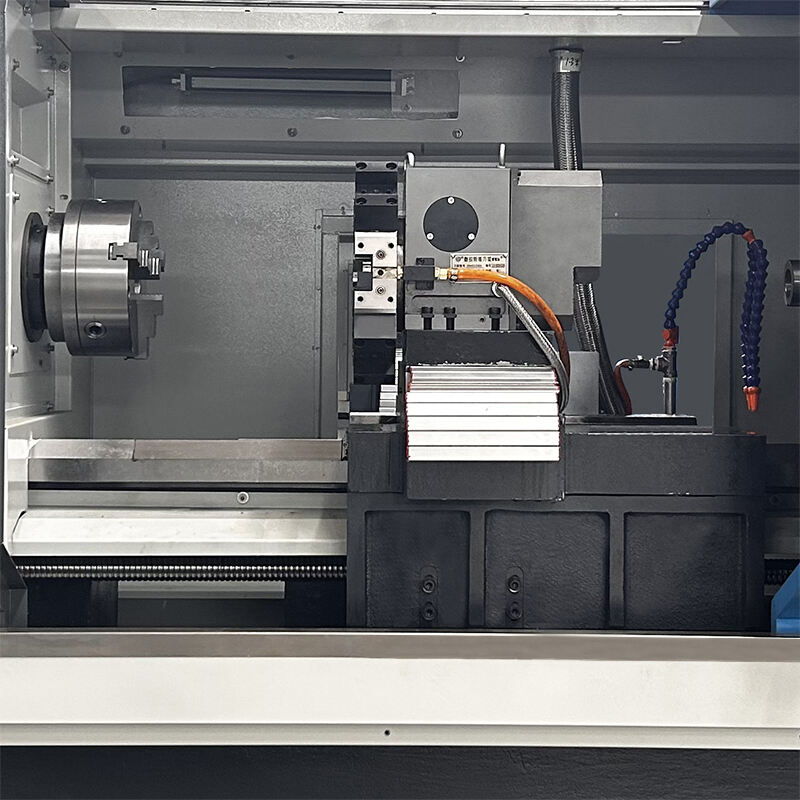

Flat bed cnc lathe

- Widened high stability bed

- The main shaft has three speed changes

- Variable frequency stepless in gear

- Widened carriage

- Automatic centralized lubrication

Introduction

Main features of CNC flat lathe:

1. Bed:

It adopts flat bed structure, resin sand molding, high-quality cast iron casting, and the upper width is 440mm (one mountain and one flat). The thickness is 90mm. The guide rail adopts medium-frequency quenching grinding and plastic pasting process, which has good wear resistance and precision retention.

2. Spindle box:

The spindle structure adopts a three-axis three-gear structure, and the spindle has high rigidity; the main drive gear is helical gear, and it is the same supplier as Shenyang Machine Tool Factory. The transmission torque is close to the national standard CK6163.

3. Feed movement

The lateral (X axis) and longitudinal (Z axis) feed movements are driven by servo motors to achieve fast movement and feed movement.

4. The imported plastic belt of the slide rail is pasted with anti-creeping, which can well ensure the positioning accuracy and repeat positioning accuracy of the machine tool.

5. Tailstock:

The design of the tailstock of the machine tool fully considers rigidity, load-bearing capacity and user-friendly. The top tightening method is manual.

6. Centralized lubrication

A centralized lubrication system is used to lubricate each guide rail pair, ball screw and bearing. The lubrication pump has functions such as working status display and hydraulic monitoring. The oil filling cycle can be adjusted at any time.

Main applications of CNC flat lathes:

Machinery manufacturing industry: such as drive shafts, spindles, lead screws, etc.

Automobile manufacturing industry: gearbox gears, differential housings, etc.

Aerospace industry: rotating parts of aluminum alloy or composite materials

Energy equipment manufacturing: spindles, gearbox parts, couplings, etc.

Mold and tooling manufacturing: plane processing and hole positioning of large templates.

General parts processing: thread processing and end surface processing of bolts and nuts.

| Specifications | Unit | CK6140 | CK6150 | CK6160 |

| Swing over bed | mm | ф400 | ф500 | ф600 |

| Swing over slide | mm | ф210 | ф290 | ф350 |

| Width of bed | mm | 360 | 400 | 440 |

| Max processing length | mm | 600/850 | 850/1350/1850 | 850/1350/1850/2850 |

| X axis travel | mm | X:210 | X:250 | X:330 |

| Spindle transmission type | - | Independent spindle/gear internal frequency conversion | Independent spindle/gear internal frequency conversion | Independent spindle/gear internal frequency conversion |

| Spindle speed | rpm | 32-1600/2000 | 20-1600/2000 | 20-1600/2000 |

| Spindle end | - | A2-6 | A2-8 | A2-8 |

| Diameter of spindle through hole | mm | Φ65 | Φ82 | ф82/105 |

| Spindle motor | kw | 5.5 | 7.5 | 11 |

| X/Z Rapid traverse | m/min | 6/8 | 6/8 | 6/8 |

| X/Z axis repeatability | mm | ±0.005 | ±0.005 | ±0.005 |

| Processing accuracy | - | IT6-IT7 | IT6-IT7 | IT6-IT7 |

| Workpiece surface roughness | - | Ra1.6 | Ra1.6 | Ra1.6 |

| Tailstock sleeve dia. | mm | Φ65 | Φ75 | ф75 |

| Quill traverse | mm | 130 | 140 | 150 |

| Sleeve taper | MT | MT4 | MT5 | MT5 |

| Tool post form | - | Electric 4-station/6 (8) station turret | ||

| Cutting tool shape size | mm | 20x20 | 25×25 | 25x25/32x32 |

| Machine dimension(LxWxH) | m | 2.5×1.42×1.66 | 2.8×1.7×1.8 | 3.1x1.8x1.85 |

| Net.weighe(approx) | t | 1.7/1.9 | 2.6/3.2 | 3.1/3.6/4.0/4.5 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.