Introduction

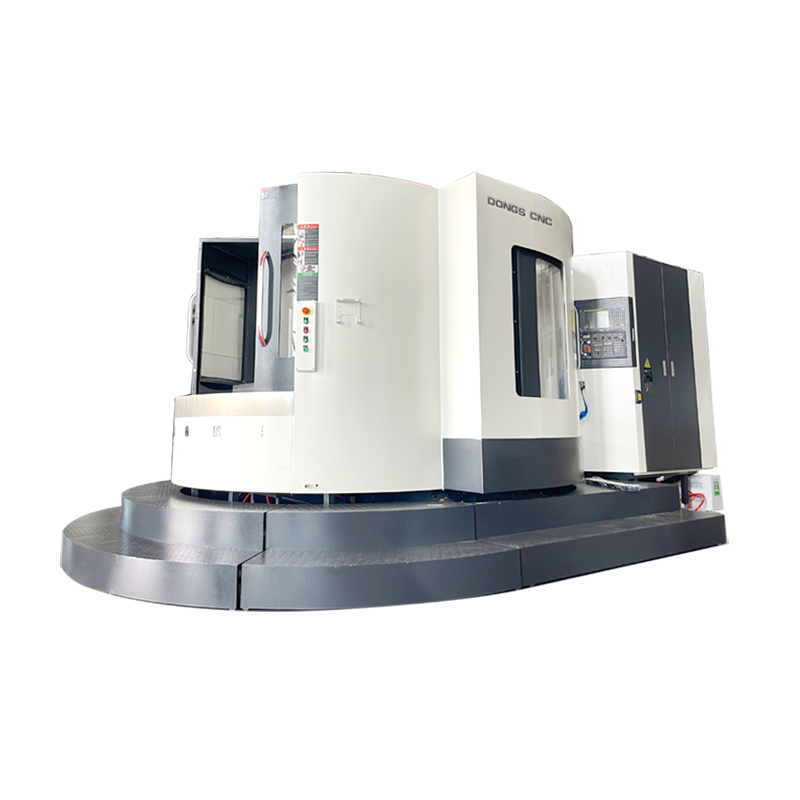

The High-Precision Horizontal Machining Center is a state-of-the-art CNC machine designed to meet the rigorous demands of large-scale metalworking applications. Featuring a horizontal spindle layout, this machining center offers exceptional stability and precision, making it ideal for high-volume production and complex machining tasks. Equipped with advanced control systems, it allows for enhanced machining accuracy and reliability, ensuring superior surface finishes and tight tolerances across a wide range of metal materials. With its robust construction and versatile capabilities, this machine excels in industries such as automotive, aerospace, and heavy machinery manufacturing.

Key Features:

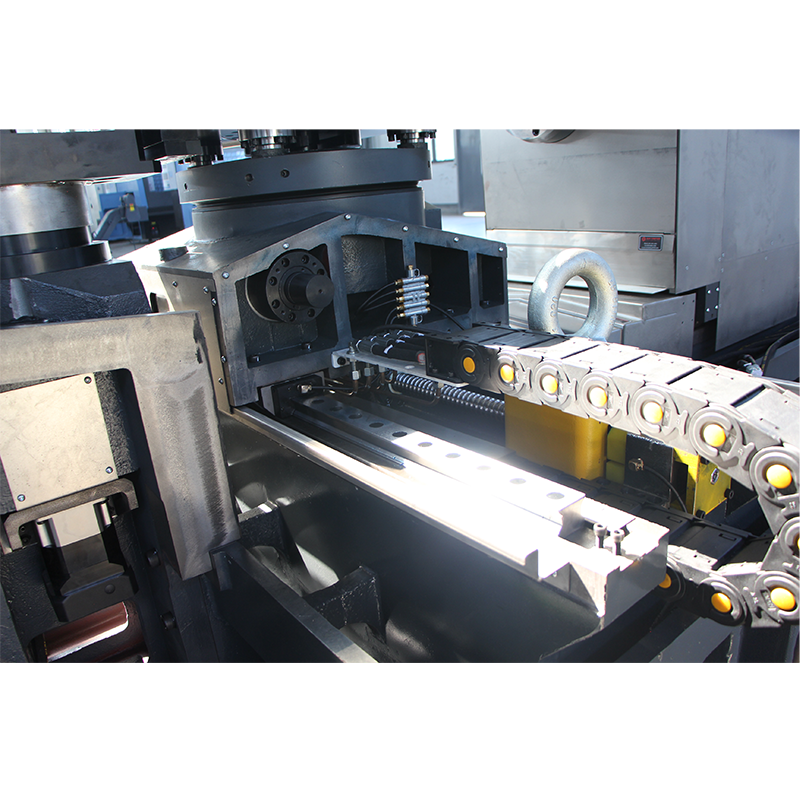

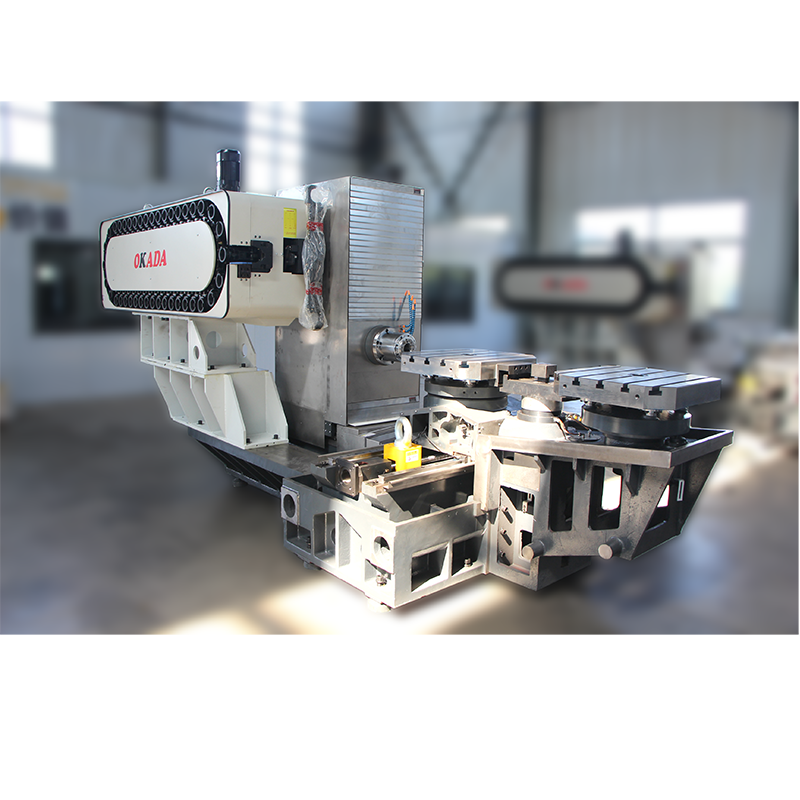

- Horizontal Spindle Design: Ensures efficient chip removal and consistent cutting performance.

- High-Speed CNC Control: Allows for precise control and complex multi-axis operations.

- Heavy-Duty Construction: Designed to handle large and heavy workpieces, ensuring stability and precision under load.

- Advanced Tool Changer: Minimizes downtime by allowing for fast tool changes, improving productivity.

- Superior Accuracy: Achieves micron-level precision for highly detailed components.

- Automated Features: Includes automatic tool measurement and error compensation for reduced operator intervention and consistent results.

- Versatile Applications: Ideal for complex parts that require multiple machining processes such as drilling, milling, and boring.

Applications:

- Automotive Manufacturing: For producing engine blocks, transmission parts, and other critical automotive components.

- Aerospace Industry: Ideal for machining complex, high-precision parts for aircraft and spacecraft.

- Heavy Machinery: Perfect for producing large-scale components for construction equipment and industrial machinery.

- Oil & Gas: Machining critical components used in drilling, extraction, and transportation of oil and gas.

- Tooling and Die Manufacturing: Precision machining for molds, dies, and tooling used in various industries.

| Specifications | Unit | TH-63/63S | TH-80 | TH-100 |

| X-axis travel | mm | 1050 | 1600 | 1600 |

| Y-axis travel | mm | 750 | 1000 | 1000 |

| Z-axis travel | mm | 900 | 1000 | 1000 |

| Number of workbenches | Individual | 1/2 | 1 | 1 |

| Workbench indexing | - | |||

| Distance from spindle face to center of worktable | mm | 130-1030 | 200-1200 | 200-1200 |

| Distance from spindle center to table surface | mm | 120-870/0-750 | 120-1120 | 120-1120 |

| Spindle speed | rpm | 6000 | 6000 | 6000 |

| Spindle taper | - | BT50-190 | BT50-190 | BT50-190 |

| Workbench area | mm | 630x700 | 800 x 800 | 1000x1000 |

| Maximum load of worktable | kg | 950 | 1500 | 1500 |

| Maximum rotary diameter of workpiece | mm | 1380/950 | 1800 | 1800 |

| X-Axis Fast Displacement | m/min | 30 | 24 | 24 |

| Y-Axis Fast Displacement | m/min | 30 | 24 | 24 |

| Z-Axis Fast Displacement | m/min | 30 | 24 | 24 |

| Cutting feed | mm/min | 10-10000 | 10-10000 | 10-10000 |

| Machine weight.(about) | T | 8.0/9.5 | 9.5 | |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.