Industrial-Grade High Rigidity Vertical Machining Center for Large-Scale Part Machining

- High quality resin sand cast iron

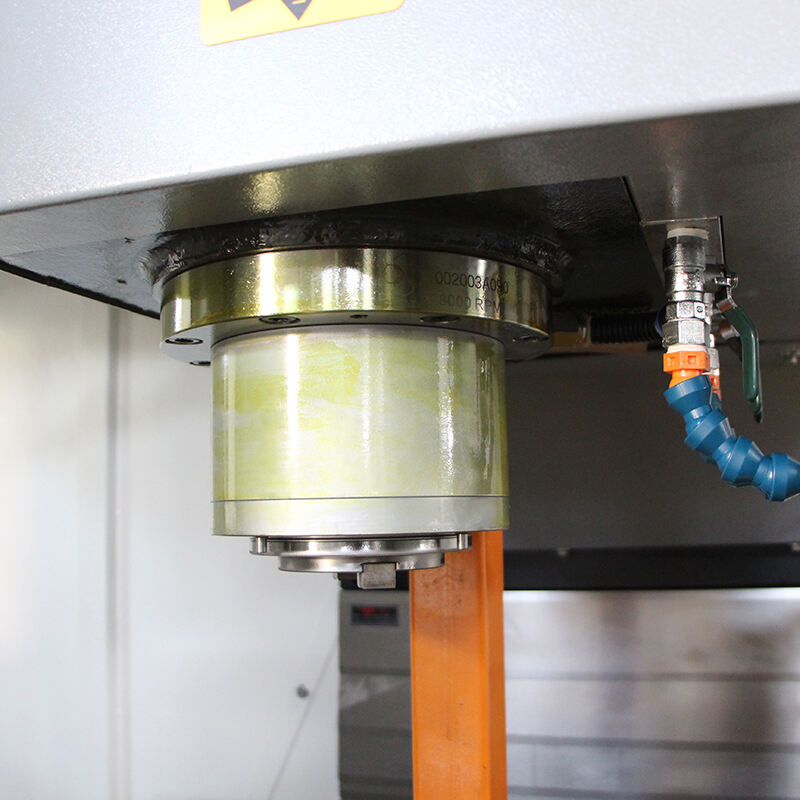

- Taiwan main axis

- Taiwan ball screw and lock nut

- Taiwan booster cylinder

- NSK bearing in Japan

- German R + W coupling

- Automatic lubrication system

- Selection of chip conveyor

Introduction

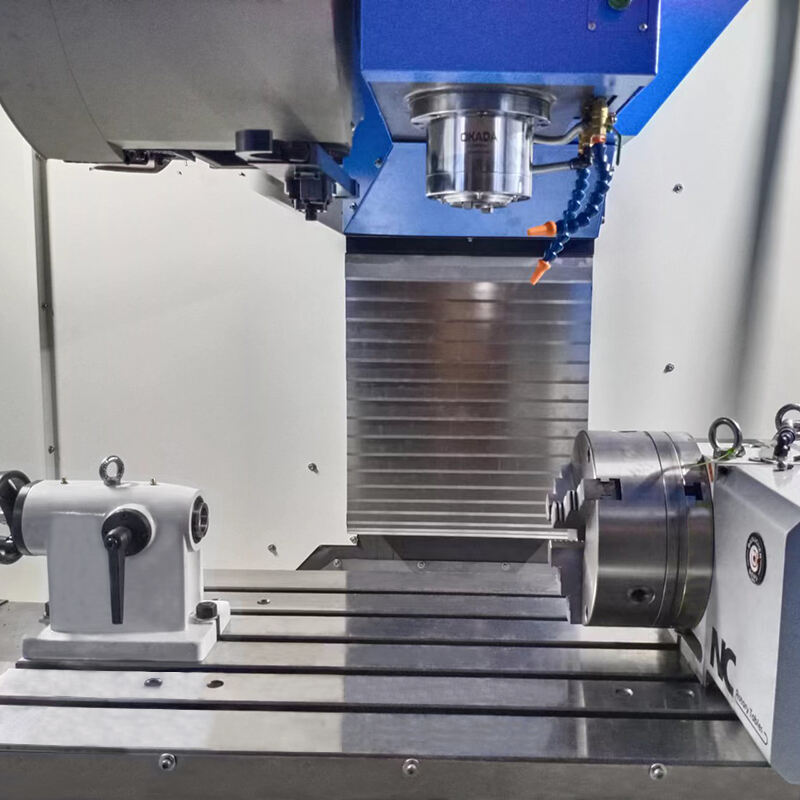

The DONGS CNC Industrial-Grade High Rigidity Vertical Machining Center is designed for high-performance, precision machining of large-scale components. Engineered to withstand demanding industrial environments, this machining center delivers exceptional accuracy and rigidity, making it ideal for high-load machining operations. The VMC features a robust design that ensures optimal performance in the production of complex parts, providing both speed and precision across a wide range of applications, including metalworking, automotive, and aerospace industries.

With advanced CNC control and a rigid frame, this vertical machining center guarantees superior part quality and machining consistency, even in the most challenging production environments. The VMC855 series maximizes productivity by combining high-speed cutting with excellent stability, making it the go-to solution for manufacturers looking to enhance their machining efficiency.

Key Features:

- High Rigidity Structure: Ensures minimal vibration, offering maximum precision and stability during heavy machining tasks.

- Powerful Spindle: Capable of handling large-scale, heavy-duty parts with precision, reducing downtime and enhancing throughput.

- CNC Control System: Features an intuitive control interface with advanced programming capabilities for complex part manufacturing.

- Large Worktable: Accommodates larger parts with a spacious worktable and increased load capacity.

- Thermal Stability: Designed with advanced materials and construction methods to reduce thermal distortion during operation, ensuring consistent performance.

- High-Speed Cutting: Delivers quick and efficient material removal while maintaining accuracy for intricate machining tasks.

- Versatile Tooling: Compatible with a wide variety of cutting tools, providing flexibility in machining diverse materials and part shapes.

- Long Operational Lifespan: Built for longevity with minimal maintenance requirements, ideal for continuous use in industrial applications.

Applications:

- Aerospace: Precision machining of complex aerospace components such as engine parts, landing gear, and structural elements.

- Automotive: High-precision part production for automotive assemblies, engine blocks, and transmission components.

- Heavy Machinery: Ideal for machining large parts such as gears, housings, and structural components used in heavy machinery manufacturing.

- Energy Sector: Manufacturing critical components for power plants, turbines, and renewable energy equipment.

- Metalworking: Versatile enough for the production of intricate parts made from metals like steel, aluminum, and titanium.

- Tool and Die Making: Producing molds, dies, and other precision tools required in various industries.

- Medical Devices: Precision machining for medical parts and equipment that require strict tolerances.

| Specifications | Unit | VMC855 | VMC850 | VMC845 |

| X-axis travel | mm | 800 | 800 | 950 |

| Y-axis travel | mm | 550 | 500 | 500 |

| Z-axis travel | mm | 550 | 500 | 500 |

| Table size(L*degrees) | mm | 1050*550 | 900*500 | 1000*450 |

| Maximum table load | kg | 600 | 500 | 450 |

| T-slot(slot number*width*pitch) | mm | 5*18*100 | 5*18*100 | 3*18*118 |

| Spindle taper | - | BT40 | BT40 | BT40-120 |

| Spindle power | kw | 7.5-11 | 7.5-11 | 7.5-11 |

| Maximum spindie speed | rpm | 8000 | 8000 | 8000 |

| Rapid traverse(X/Y/Z) | m/min | 48/48/36 | 48/48/36 | 24/24/24 |

| Cutting feed | mm/min | 1-8000 | 1-8000 | 1-8000 |

| Feed motor | nm | 20/20/20 | 20/20/20 | 10/10/15 |

| Spindle nose to table | mm | 130-660 | 130-630 | 120-650 |

| Spindle center to columnsurface distance rail | mm | 590 | 525 | 466 |

| Maximum tool diameter | mm | Φ78/120 | Φ78/120 | Φ78/120 |

| Maximum table length | mm | 250/350 | 250/350 | 250/350 |

| Maximum table weight | kg | 8 | 8 | 7 |

| Positioning accuracy | mm | ±0.0075 | ±0.0075 | ±0.008 |

| Repeat accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Electric capacity | kva | 15 | 15 | 15 |

| Machine weight.(about) | t | 6 | 5.6 | 4.2 |

| Dimensions | m | 2.8*2.4*2.8 | 2.7*2.3*2.8 | 2.6*2.2*2.6 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.