Gantry milling machine

- High strength cast iron

- Taiwanese ball screw and lock nut

- Japan NSK bearing

- Automatic lubrication system

- Taiwan spindle’

- Taiwan pressure cylinder

- Germany R+W coupling

- Chip conveyor at optional

Introduction

The GM series of CNC gantry machining centers inherits the advantages of traditional gantry machine tools, such as strong rigidity of the basic frame, symmetrical structure, and stability. By strengthening the reinforcement structure and reasonable layout, the whole machine has strong rigidity. It has multiple processing functions such as milling, boring, drilling (expansion, reaming), and tapping, and is commonly used in various mechanical processing fields such as automobiles, molds, aerospace, packaging, and hardware.

1. Main structure

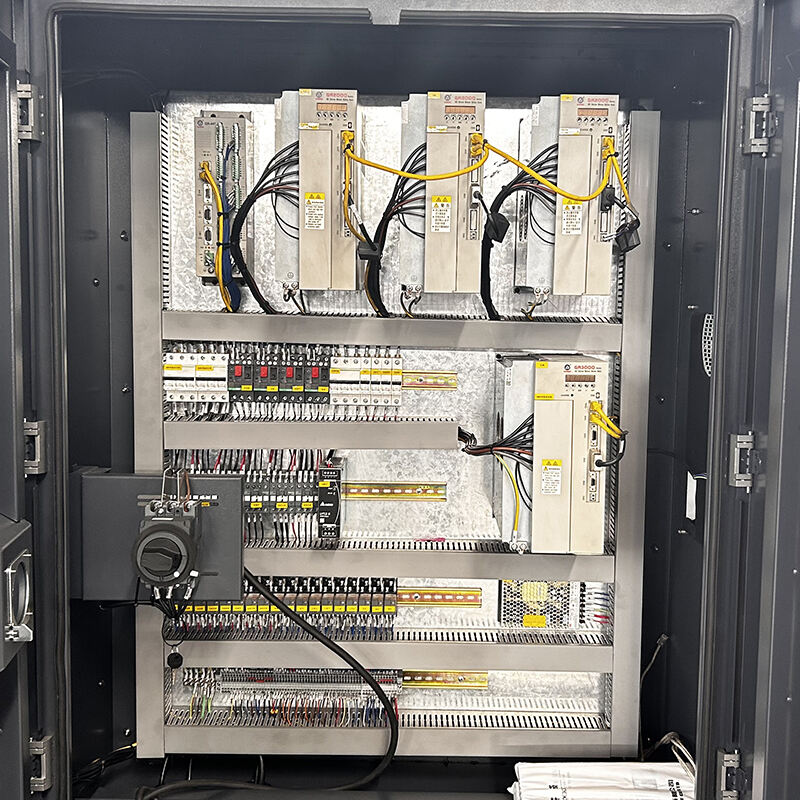

The machine tool has a fixed gantry frame and a movable worktable structure. It is mainly composed of a worktable, a bed, a column, a crossbeam, a ram, a hydraulic system, a lubrication system, a cooling and filtering system, a chip removal device, a rotary operation panel, and an electronic control system.

Definition of each coordinate axis:

X axis: the worktable moves forward and backward longitudinally on the bed;

Y axis: the ram and saddle parts move left and right horizontally along the guide rail on the crossbeam;

Z axis: the ram moves up and down vertically along the guide rail on the saddle;

2. Bed (X axis)

The bed and worktable materials are both made of high-strength cast iron and resin sand molding. The X-axis guide rail adopts a heavy-duty guide rail support structure. The position and number of high-load-bearing sliders are reasonably arranged on each roller linear guide according to the principle of mechanics, so that the machine tool can obtain high rigidity and long-term stable accuracy.

The transmission system adopts an AC servo motor to drive the heavy-duty ball screw to rotate and realize the linear forward and reverse motion of the X-axis. The screw support adopts a fixed pre-stretching structure at both ends.

3. Column

The large column and crossbeam parts are made of high-strength cast iron and resin sand molding.

4. Saddle (Y axis)

The saddle parts are made of high-strength cast iron and resin sand molding.

The Y-axis crossbeam has a dense cross-rib structure with high rigidity, good kinetic energy characteristics, and good precision retention, ensuring that the machine tool can run smoothly for a long time under full load and low speed.

The transmission system uses an AC servo motor to drive the ball screw to rotate and realize the linear reciprocating motion of the Y-axis.

5. The Z-axis adopts a double-rod nitrogen balance cylinder structure with a simple structure and easy maintenance.

Main applications of gantry machining centers:

Aerospace (structural parts, wing frames)

Automobile manufacturing: molds, car bodies

Energy equipment: wind power components, turbines

Heavy machinery: machine tool beds, mining equipment

Rail transportation: car bodies, bogies

Ships: hull structures

Molds: large injection molds, die-casting molds

| Name | Unit | GMC1613 | GMC1813 | GMC2016 | GMC2518 | |

| staging | Table size | mm | 1600*1000 | 2000*1000 | 2000*1300 | 2500*1600 |

| Bearing capacity of workbench | Kg | 2000 | 3000 | 4000 | 7000 | |

| T-type groove width | mm | 7*22*140 | 7-140*22 | 7-170*22 | 9-180*22 | |

| range of work | X axis travel | mm | 1600 | 2000 | 2000 | 2500 |

| Y axis travel | mm | 1300 | 1300 | 1650 | 1800 | |

| Z axis travel | mm | 800 | 800 | 800 | 1000 | |

| Distance from spindle end face to workbench |

mm | 190-990 | 190-990 | 250-1050 | 150-1150 | |

| longmen too wide | mm | 1300 | 1300 | 1660 | 1800 | |

| principal axis |

Taper hole model | BT40 | BT50 | BT50/Ф 190 | BT50/Ф 190 | |

| Pull nail specification | P40T-1-MAS403(45°) | P50T-1-MAS403(45°) | P50T-1-MAS403(45°) | 10-6000 | ||

| range of speeds | rpm | 10-8000 | 10-8000 | 10-6000 | ||

| tool | ATC | T | 24 | 24 | 24 | 24 |

| FEED | Cut into the feed speed range | m/min | 1-10 | 1-10 | 1-10 | 1-7 |

|

X-axis fast movement |

m/min | 18 | 15 | 15 | 15 | |

| Y-axis rapid movement | m/min | 18 | 15 | 15 | 15 | |

| Z-axis rapid movement | m/min | 12 | 15 | 15 | 10 | |

|

system configuration |

Fanuc |

|||||

| Motor configuration |

X-axis motor | Nm | 11 | 20 | 20 | 30 |

| Y-axis motor | Nm | 11 | 20 | 20 | 20 | |

| Z-axis motor | Nm | 11 | 20 | 20 | 20 | |

| Spindle motor | Kw | 11--15 | 15-18.5 | 15-18.5 | 22 | |

| Drive configuration | guide rail specification (XYZ) | X | 45 | 45 | 55 | 55 |

| Y | 45 | 55 | 55 | 55 | ||

| Z | box | box | box | box | ||

| screw specification (XYZ) | X | 5012 | 6312 | 6312 | 6312 | |

| Y | 5012 | 5010 | 5010 | 5010 | ||

| Z | 5012 | 5010 | 5010 | 5010 | ||

| Overall dimension | mm | 5200*2500*3200 | 5300*3500*3800 | 5700*2500*3100 | 7300*4300*4000 | |

| Weight | T | 11 | 16 | 20 | 25 | |

| Optional configuration:Spindle center water outlet 2/5 MPa BF gearbox Germany Heidenham grating ruler | ||||||

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.