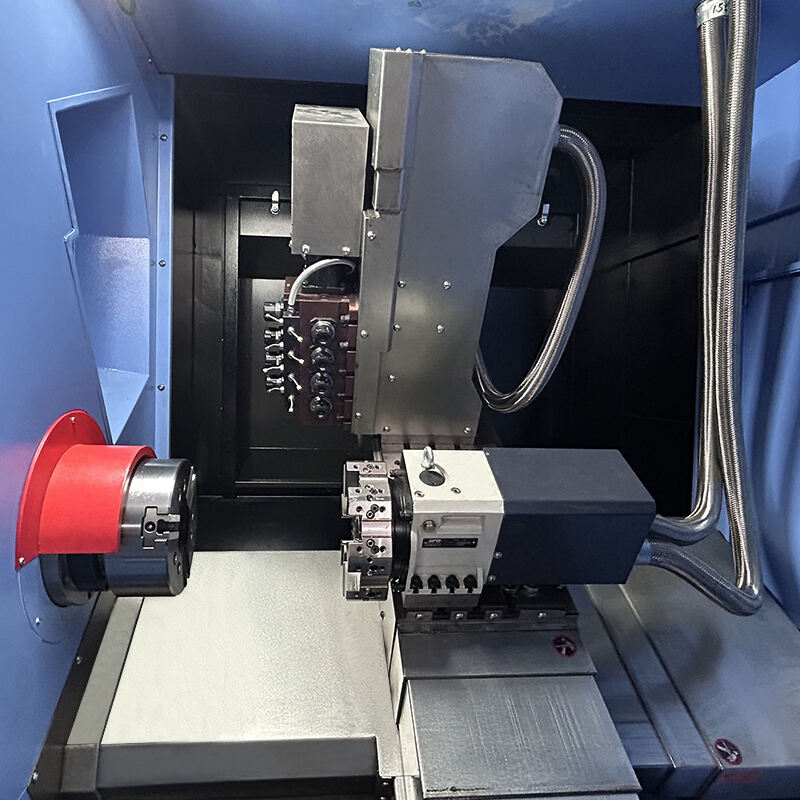

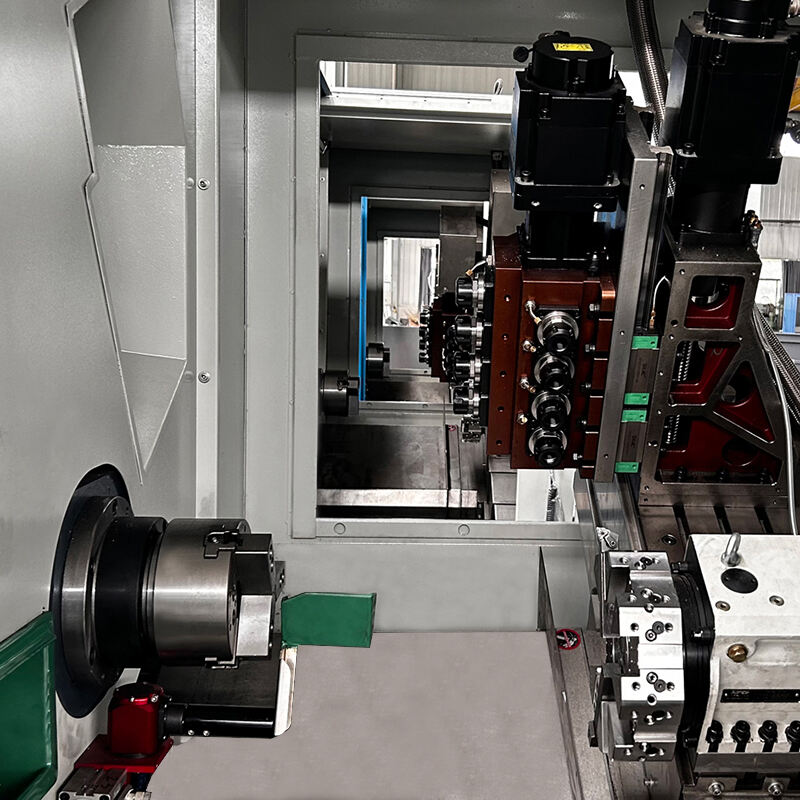

nc lathe

- High precision Roller linear guide

- High precision ball screw

- Imported precision bearing

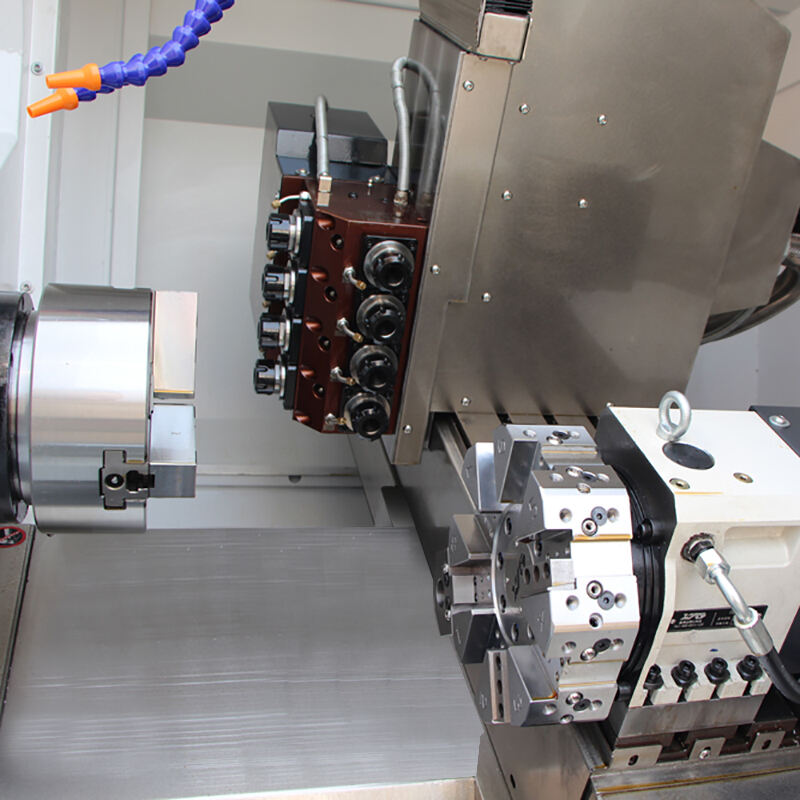

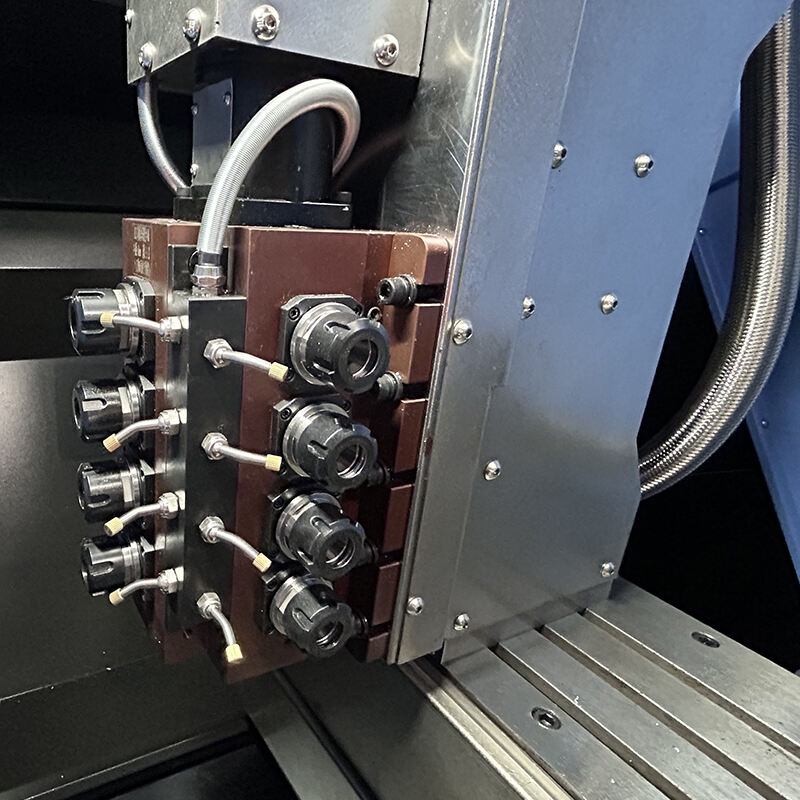

- 8-station servo hydraulic turret

- Group live tooling

-

8-position haydraulic chuck

Introduction

Main features of nc lathe

1. Hi thilri nih hin aa tluk tein aa tlukmi ihkhun suaisamnak a hman, rang tukin lehnak le a dikthliar in tuahsernak tthatnak hna kha a fonh. A hrampi dirkamhnak thilri cu ralkap-tluk in fehtermi thir thilri in sermi a si i chunglei hnahnawhnak hloh awkah tarnak in zohkhenh a si, caan sau le a tam tukmi riantuannak chungah thilri hna i an i thlen khawhnak kha a hngalhter.

2.30 degree aa fonhmi a tlikmi ihkhun he a ttha ngaimi tliknak linear lamhruainak system he a ttha bikmi chip chuah khawhnak lam a ser. Hi suaisam nih hin a ttha tein chiah khawhnak lawng si loin, chip khonnak zong ttha tein a hrial i chanthar a dikthliar in hmanmi thilri hna i a rang tukmi thlehnak a herhmi he aa tlak.

3. A rangmi, a dikthliar tukmi, a fekmi barrel-type spindle unit le servo spindle motor nih spindle rangnak sang deuh an hmuh khawh. Spindle unit cu aa thleng lomi lumnak khaan ah an fonh, cun an fonh hnu suimilam 72 chung aa thleng lomi lumnak ah an hman, cun a rang tukmi le a dikthliar in riantuan khawhnak ding caah seh cungah an chiah hnu suimilam 72 chung pehzulh tein an hman.

4.Dual-axis drive system cu 35mm kau lamhruaitu tlanglawng module, 410mm span layout le 210mm center support platform he aa tlum. A ritmi tannak dirhmun tangah thlehnak kong chimrelnak kha ttha tein kham law a muisam tlaih khawhnak kha tthanchoter.

nc lathe main applications:

Automotive Industry: For machining high-precision components such as engine parts, transmission components, and brake systems.

Aerospace: Suitable for the production of complex aerospace parts, including turbine blades, engine components, and structural components.

General Engineering: Machining a variety of parts for different manufacturing applications, including gears, shafts, and housings.

Metalworking: Suitable for mass production of metal parts, providing high productivity and consistency for high-volume production.

Defense Manufacturing: Machining high-tolerance parts for military equipment and systems.

Medical Devices: Precision machining of medical devices and instrument components.

Renewable Energy: Producing parts for wind turbines, solar panels, and other renewable energy technologies.

| Specifications | Unit | TCK50CY |

| Max Swing Over Bed | Mm | Φ510 |

| Max Swing Over Slide | Mm | Φ200 |

| Max Turning Diameter | Mm | Φ200 |

| Spindle Head Type | - | A2-6 |

| Spindle Through-Hole Diameter | Mm | Φ80 |

| Bar Capacity | Mm | 55/65 |

| Max Spindle Speed | Rpm | 4200/3500 |

| Main Motor Power | KW | 7.5-11 |

| Hydraulic Chuck | Inch | 8 |

| Positioning accuracy | mm | ±0.01 |

| Repeatability (X/Y/Z) | mm | ±0.005 |

| Max Spindle Speed | RPM | 1000-4000 |

| Cutting torque | N.m | 10 |

| X-Axis Travel | Mm | 1100 |

| Z-Axis Travel | Mm | 550 |

| X/Z Fast Moving Speed | M/Min | 24/24 |

| Turret type | - | Group live tooling |

| Adjacent Tool Change Times | S | 0.5 |

| Number Of Station | - | 8 |

| Spring Chuck | - | ER25 |

| Y-Axis Travel | Mm | ±220 |

| Dimensions | M | 2900*2000*2300 |

| Machine Weight (Approx) | KG | 3000 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.