Slant Bed CNC Lathe for High-Precision Turning of Complex Geometries

- High precision Roller linear guide

- High precision ball screw

- Imported precision bearing

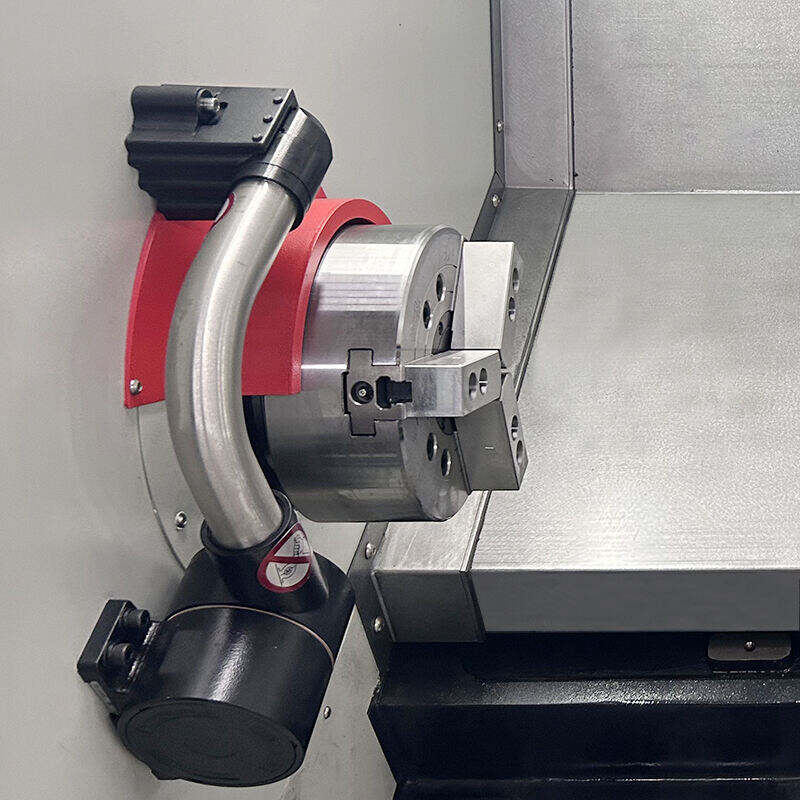

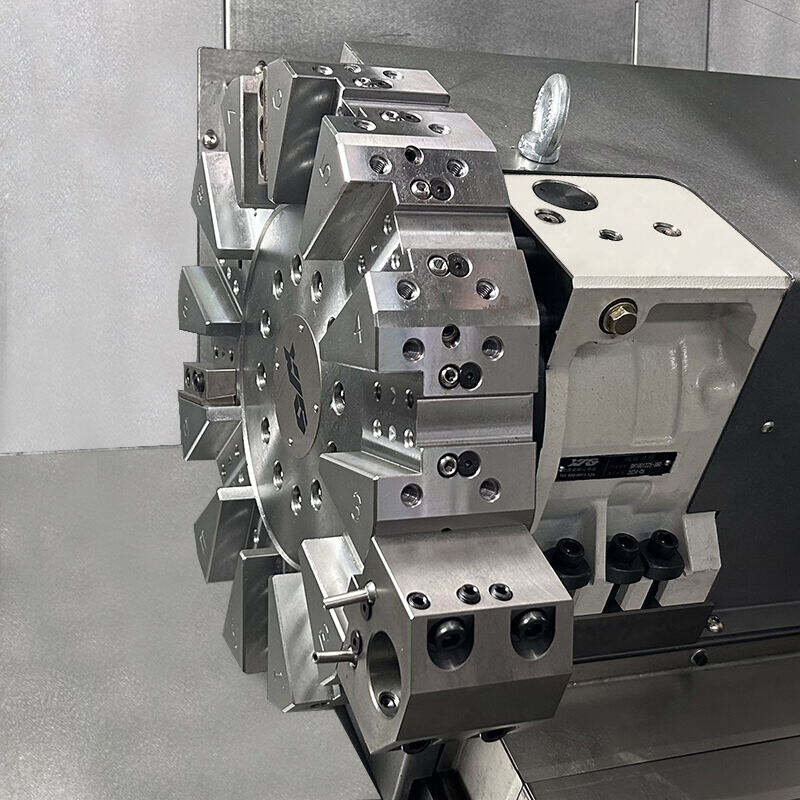

- Servo hydraulic turret

- Optional 12 Station live tooling

- Tool setting instrument is optional

- Main shaft synchronous belt drive

Introduction

The Slant Bed CNC Lathe by DONGS CNC is engineered to deliver unmatched precision and efficiency in machining complex geometries. Designed with a slant bed structure, this lathe enhances rigidity and stability, minimizing vibrations during high-speed operations. Equipped with advanced CNC controls, it ensures consistent, repeatable results for intricate designs. Ideal for industries requiring accuracy and reliability, this lathe is your go-to solution for turning, milling, and drilling applications.

Key Features:

- Slant Bed Design: Provides superior rigidity and stability, reducing vibration and ensuring high precision.

- Advanced CNC Control: Features intuitive programming for seamless and automated operations.

- High-Speed Spindle: Ensures efficient machining of tough materials, including alloys and stainless steel.

- Heavy-Duty Construction: Built to withstand demanding industrial environments, ensuring durability and reliability.

- Versatile Tooling Options: Supports various tools for turning, milling, and drilling processes.

- Compact Footprint: Ideal for workshops with limited space, maximizing productivity.

Applications:

- Automotive Industry: Precision machining of engine components, shafts, and gears.

- Aerospace: Crafting complex parts like turbine blades and landing gear components.

- Medical Device Manufacturing: Producing surgical instruments and implants with stringent tolerances.

- General Machining: Suitable for creating high-precision parts for industrial machinery and electronics.

- Custom Part Production: Ideal for prototyping and small-batch production with intricate designs.

| CAPACITY | Unit | TCK52 | ||

| Distance between centers | mm | 650 | 850 | 1070 |

| Chuck size | inck | 8 | ||

| Max. swing over bed | mm | 560 | ||

| Max. swing over cross slide | mm | 280 | ||

| Linear guide rail width | mm | 45/45 | ||

| TRAVELS | ||||

| X-Axis Rapid Traverse | m/min | 20 | ||

| Z-Axis Rapid Traverse | m/min | 20 | ||

| X axis travel | mm | 270 | ||

| Z axis travel | mm | 610 | 830 | 1070 |

| MAIN SPINDLE | ||||

| Max. Spindle Speed | rmp | 4200 | ||

| Max. Spindle Power | kw | 11 | ||

| Spindle nose | - | A2-6 | ||

| bar capacity | mm | 52 | ||

| TURRET | ||||

| No. of tool station | - | 12 | ||

| Turret Type | - | 12-station hydraulic servo turret | ||

| tailstock | ||||

| quill diameter | mm | 80 | ||

| quill travel | mm | 80 | ||

| tailstock Travel | mm | 500 | 700 | 950 |

| tailstock taper | - | MT5 | ||

| DIMENSIONS | ||||

| Packing size | m | 3.35 | 3.6 | 4 |

| Width | m | 2 | 2 | 2 |

| Height | m | 2.3 | 2.3 | 2.3 |

| NET Weight | kg | 4000 | 4300 | 4800 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.