Slant Bed CNC Lathe with User-Friendly Control for Small to Large Manufacturing Projects

- High precision Roller linear guide

- High precision ball screw

- Imported precision bearing

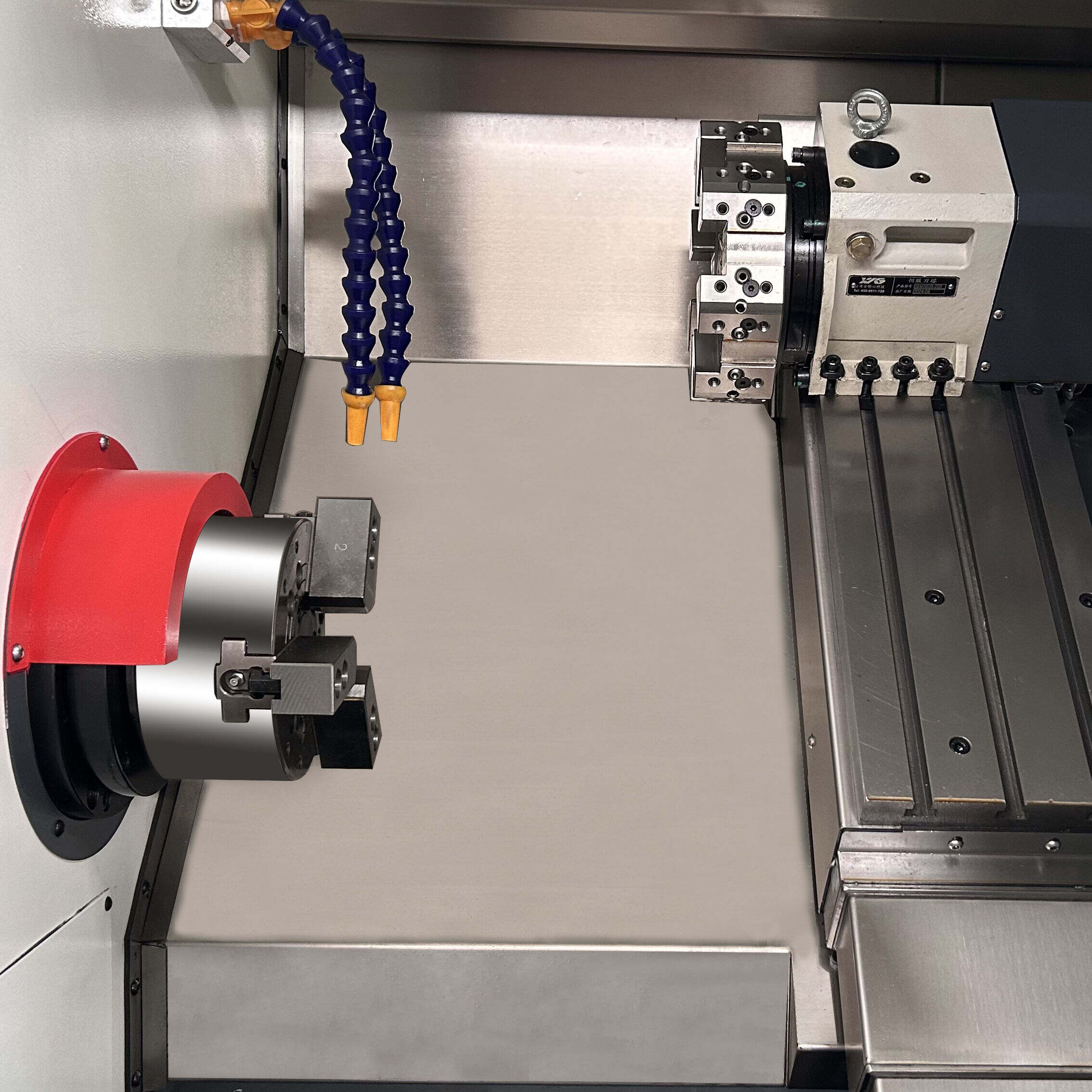

- Optional combined power milling head

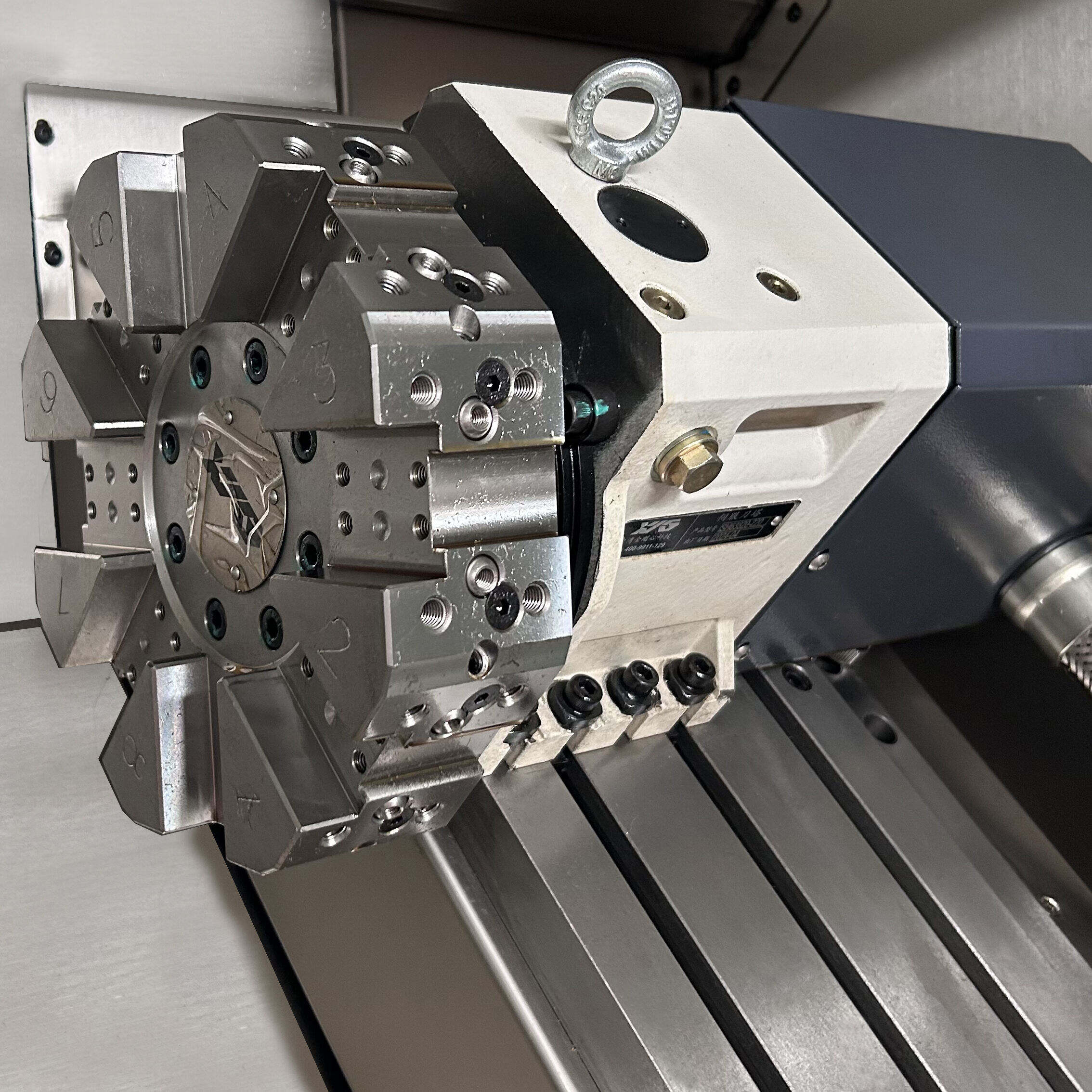

- Optional multi station turret

- Optional 12 Station live tooling y-axis

- Main shaft synchronous belt drive

Introduction

The Slant Bed CNC Lathe with User-Friendly Control by DONGS CNC is a versatile and high-performance machining solution designed to meet the needs of modern manufacturing. With its advanced slant bed design, this lathe provides exceptional rigidity, accuracy, and ease of use, making it suitable for both small-scale workshops and large industrial production lines. Engineered for precision and efficiency, this lathe is the ideal choice for manufacturers seeking reliable and cost-effective machining of complex parts and components.

Key Features:

- Ergonomic Slant Bed Design: Ensures superior stability and minimizes vibration for high-precision machining.

- User-Friendly CNC Control: Intuitive interface for easy programming and seamless operation.

- High Rigidity and Durability: Built with robust materials to handle heavy workloads and maintain long-term performance.

- Multi-Material Compatibility: Capable of machining a wide range of materials, including metals and alloys.

- Flexible Production Capacity: Suitable for small-batch and large-scale production runs, catering to diverse manufacturing needs.

- Advanced Spindle Technology: Offers high-speed operation with exceptional accuracy, reducing production times.

- Compact and Space-Saving: Optimized for workshops with limited space without compromising performance.

Applications:

- Automotive Industry: Manufacturing precision components such as gears, shafts, and engine parts.

- Aerospace Sector: Producing high-tolerance parts like turbine blades and structural components.

- Medical Equipment: Fabricating surgical tools, implants, and other intricate medical devices.

- General Metalworking: Creating custom parts for industrial machinery and electronic devices.

- Tool and Die Making: Crafting molds, dies, and other tooling with exceptional detail and accuracy.

- Prototyping and R&D: Developing prototypes and testing new designs for product innovation.

| CAPACITY | Unit | TCK40 | TCK46 | TCK50 |

| Distance between centers | mm | / | ||

| Chuck size | inck | 6 | 8 | |

| Max. swing over bed | mm | 400 | 460 | 510 |

| Max. swing over cross slide | mm | 125 | 150 | 180 |

| Linear guide rail width | mm | 25/30 | 30/30 | 35 |

| TRAVELS | ||||

| X-Axis Rapid Traverse | m/min | 24 | 24 | 24 |

| Z-Axis Rapid Traverse | m/min | 24 | 24 | 24 |

| X axis travel | mm | 800 | 900 | 1100 |

| Z axis travel | mm | 400 | 340 | 500 |

| MAIN SPINDLE | ||||

| Max. Spindle Speed | rpm | 4500 | 4500 | 4200 |

| Max. Spindle Power | kw | 5.5 | 7.5 | 11 |

| Spindle nose | - | A2-5 | A2-5 | A2-6 |

| bar capacity | mm | 41 | 46 | 52 |

| TURRET | ||||

| No. of tool station | - | 8 | 8 | 8 |

| Turret Type | - | Cutting tool/8-station turret | 12-station hydraulic servo turret | |

| tailstock | ||||

| quill diameter | mm | NO | ||

| quill travel | mm | |||

| tailstock Travel | mm | |||

| tailstock taper | - | |||

| DIMENSIONS | ||||

| Packing size | m | 2.3 | 2.5 | 2.9 |

| Width | m | 1.6 | 1.7 | 2 |

| Height | m | 2.2 | 2.2 | 2.3 |

| NET Weight | kg | 1700 | 2450 | 2850 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.