Top-Rated High-Precision 5-Axis CNC Machining Center for High-Tolerance Manufacturing

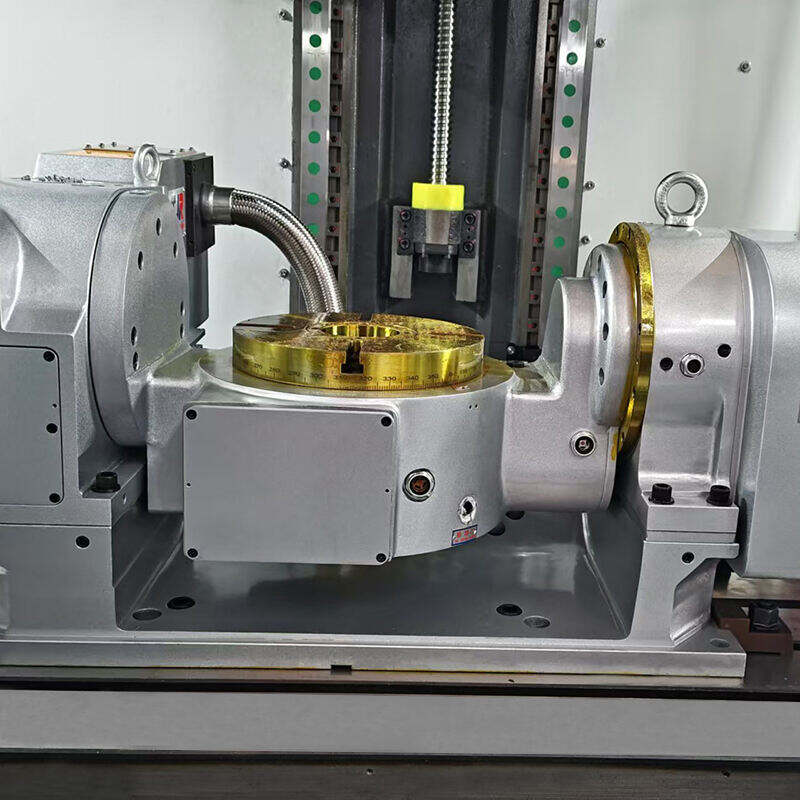

- 5-axis CNC turntable

- High quality resin sand cast iron

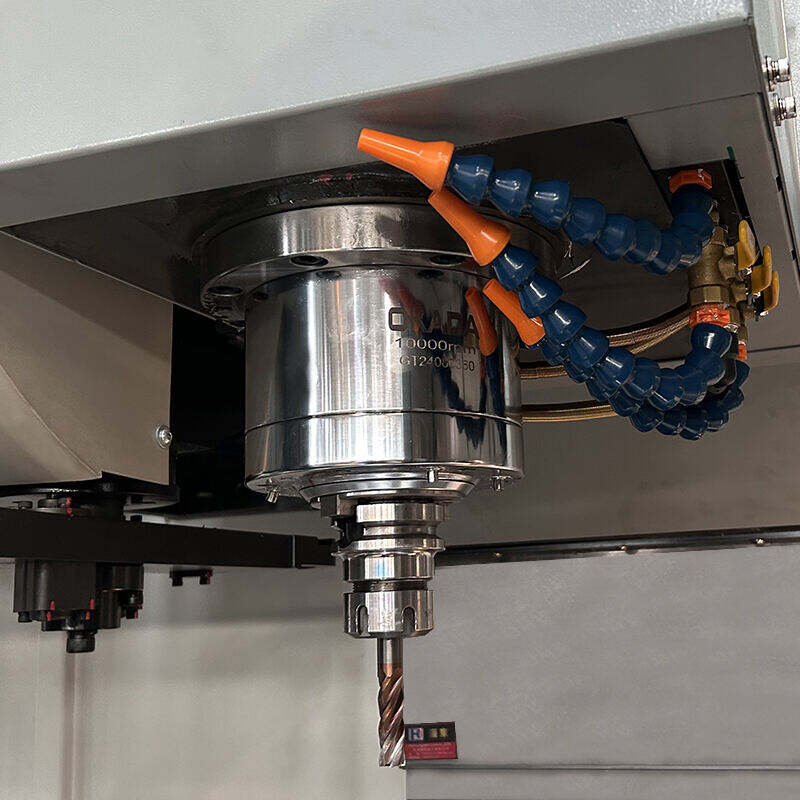

- Taiwan main axis

- Taiwan ball screw and lock nut

- Taiwan booster cylinder

- German R + W coupling

- Automatic lubrication system

- Selection of chip conveyor

Introduction

The Top-Rated High-Precision Vertical Machining Center offers unparalleled accuracy and versatility, making it an ideal choice for high-tolerance manufacturing across a wide range of industries. Designed with advanced engineering and cutting-edge technology, this vertical machining center ensures optimal performance for both small and large-scale production runs. Whether you’re working with intricate parts or high-volume production, this machine provides exceptional precision, speed, and reliability for all your machining needs.

Built for heavy-duty operations, this vertical machining center guarantees consistent results, even under the most demanding conditions. Its user-friendly interface, combined with robust construction, makes it suitable for both seasoned professionals and new operators. Equipped with powerful spindles and advanced control systems, it’s the perfect solution for those looking to enhance productivity without compromising on quality.

Key Features:

- High Precision: Capable of achieving tight tolerances, ensuring reliable and accurate parts.

- Robust Design: Built to withstand heavy workloads and maintain performance over extended periods.

- Advanced Control System: Equipped with an intuitive CNC control panel for easy operation and programming.

- Powerful Spindle: Offers high-speed cutting capabilities for improved efficiency and surface finish.

- Flexible Tool Capacity: Supports multiple tool changers for faster production and minimal downtime.

- Efficient Cooling System: Ensures optimal performance even during high-speed operations.

- User-Friendly Interface: Simplifies machine operation, making it accessible to both experienced and new users.

Applications:

- Automotive Manufacturing: Ideal for precision machining of engine parts, gearbox housings, and suspension components.

- Aerospace Components: Perfect for high-precision manufacturing of complex parts like turbine blades and brackets.

- Medical Device Manufacturing: Used to create intricate and precise parts for medical tools, implants, and diagnostic devices.

- Mold Making: Excellent for producing high-precision molds for injection molding or die casting.

- Tooling and Fixture Production: Suitable for manufacturing high-quality jigs, fixtures, and tooling used in various industries.

- Electronics Industry: Used for the precise machining of components such as connectors, enclosures, and housings.

- General Precision Engineering: Versatile enough for a wide range of industries requiring tight tolerances and complex geometries.

| Specifications | Unit | VMC1160 |

| X-axis travel (left and right) | mm | 1100 |

| Y-axis travel (front and rear) | mm | 600 |

| Z-axis travel (up and down) | mm | 600 |

| Distance from nose end of main shaft to working surface | mm | 120-720 |

| Distance from spindle center to column rail surface | mm | 650 |

| Table size (x-axis direction) | mm | 1200 |

| Table size (Y-axis direction) | mm | 600 |

| T-groove of worktable | mm | 18X5X100 |

| Maximum load of worktable | kg | 800 |

| Spindle speed (belt drive) | rpm | 12000 |

| Recommended horsepower of spindle | kW | 11--15 |

| Taper of main shaft inner hole | - | BT40-150 |

| G00 rapid feed (X/Y/Z axis) | m/min | 36/36/36 |

| G01 cutting feed | mm/min | 1-8000 |

| Servo motor specifications | kW | 3 X 3 X 3 |

| Magazine capacity | ATC | Arm 24 |

| Weight approximately | KG | 6300 |

| Dimensions | m | 4420*2280*2550 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.