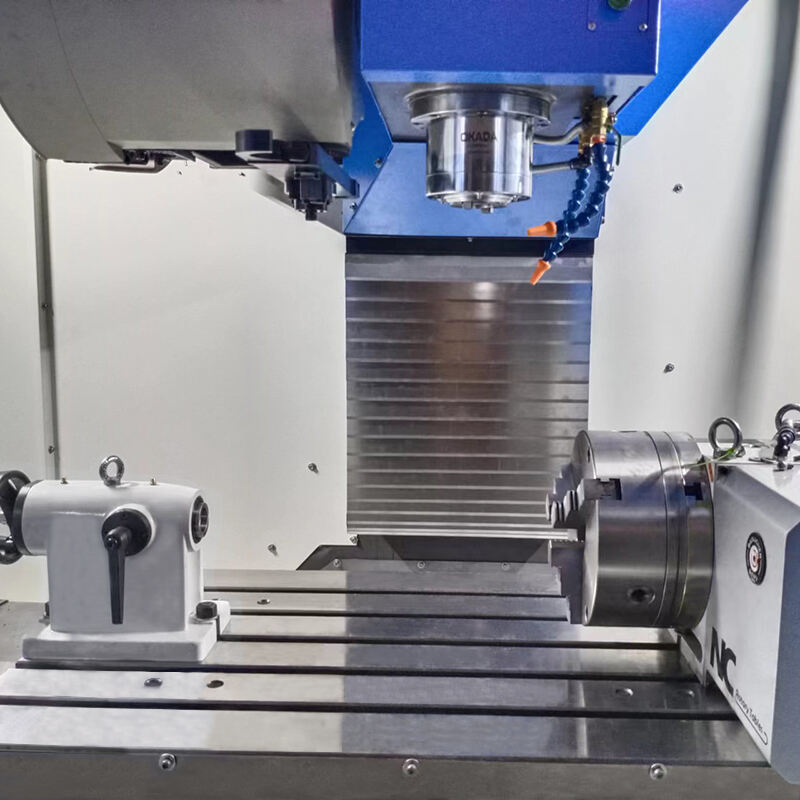

vmc machine

- High quality resin sand cast iron

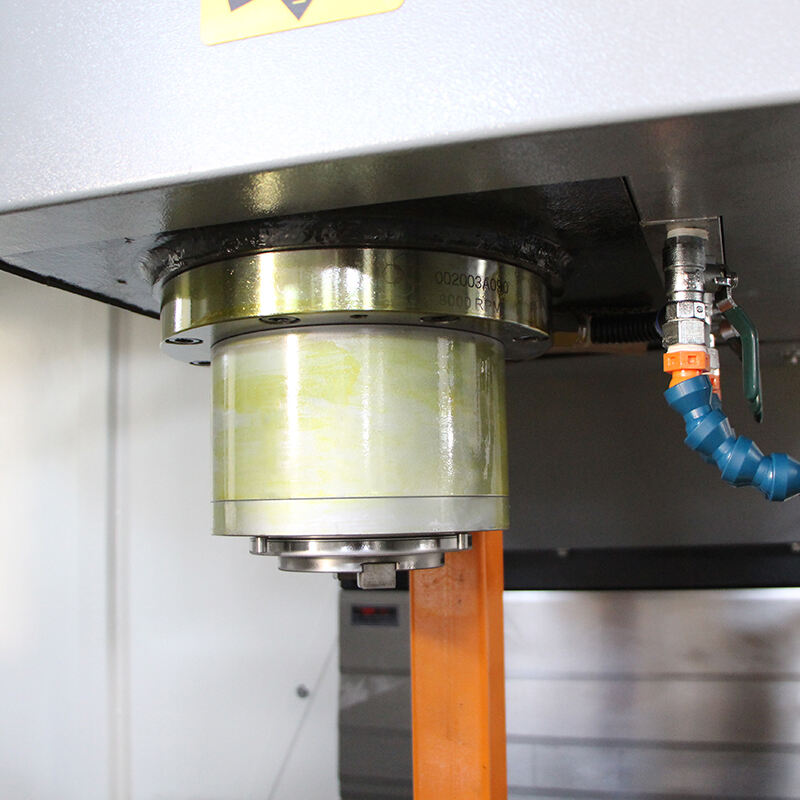

- Taiwan main axis

- Taiwan ball screw and lock nut

- Taiwan booster cylinder

- NSK bearing in Japan

- German R + W coupling

- Automatic lubrication system

- Selection of chip conveyor

Introduction

Main features of vmc machine

DONGS CNC high-rigidity vertical machining center is specially designed to meet the needs of industrial heavy-duty machining, and is optimized for efficient and precise machining of large workpieces. The equipment adopts a reinforced body structure, which can maintain excellent machining accuracy in harsh production environments, and is particularly suitable for high-intensity cutting operations in metal processing, automobile manufacturing, and aerospace fields. Its stable and reliable performance design ensures optimal production efficiency during the machining of complex parts.

This series of machining centers is equipped with an intelligent CNC system and an anti-deformation frame structure, which can maintain stable process quality even under long-term continuous processing conditions. The VMC855 series optimizes the balance between dynamic response and structural rigidity, perfectly combining efficient cutting and processing stability, becoming a core equipment solution for improving corporate productivity.

Strengthened body structure: effectively suppress machining vibration through optimized mechanical design to ensure machining accuracy under heavy cutting conditions

High-power spindle system: supports efficient machining of large-sized workpieces, significantly shortens machining cycle and improves production capacity

Intelligent CNC system: integrates human-machine interaction interface and intelligent programming module to meet the machining needs of parts with complex geometric shapes

Wide-range machining platform: equipped with large-size worktable and enhanced bearing system, suitable for clamping of various oversized workpieces

Thermal balance technology: applies new composite materials and thermally symmetrical structural design to effectively control the thermal displacement of equipment

Efficient cutting performance: while achieving fast material removal rate, ensure the dimensional consistency of precision machining features

Multi-axis linkage function: supports a variety of tool combination solutions, and flexibly responds to the machining needs of special-shaped parts and composite materials

Industrial-grade durability: adopts long-term design concept and modular structure to reduce equipment maintenance frequency and operating costs

Main applications of vmc machine

Aerospace: Manufacturing of high-precision parts such as aircraft engine components and aircraft structural parts

Automotive industry: Mass production of key components of powertrain and precision components of transmission system

Heavy equipment manufacturing: Comprehensive processing of large gearboxes and heavy structural parts of engineering machinery

Energy equipment: Manufacturing of core components of generator sets and precision components of new energy equipment

Metal forming: Multi-process processing of complex components of special alloys and lightweight metal materials

Tooling and mold industry: Manufacturing of precision injection molds, die-casting molds and forming tools

Medical device production: Micron-level processing of implantable devices and precision components of high-end medical equipment

| Specifications | Unit | VMC855 | VMC850 | VMC845 |

| X-axis travel | mm | 800 | 800 | 950 |

| Y-axis travel | mm | 550 | 500 | 500 |

| Z-axis travel | mm | 550 | 500 | 500 |

| Table size(L*degrees) | mm | 1050*550 | 900*500 | 1000*450 |

| Maximum table load | kg | 600 | 500 | 450 |

| T-slot(slot number*width*pitch) | mm | 5*18*100 | 5*18*100 | 3*18*118 |

| Spindle taper | - | BT40 | BT40 | BT40-120 |

| Spindle power | kw | 7.5-11 | 7.5-11 | 7.5-11 |

| Maximum spindie speed | rpm | 8000 | 8000 | 8000 |

| Rapid traverse(X/Y/Z) | m/min | 48/48/36 | 48/48/36 | 24/24/24 |

| Cutting feed | mm/min | 1-8000 | 1-8000 | 1-8000 |

| Feed motor | nm | 20/20/20 | 20/20/20 | 10/10/15 |

| Spindle nose to table | mm | 130-660 | 130-630 | 120-650 |

| Spindle center to columnsurface distance rail | mm | 590 | 525 | 466 |

| Maximum tool diameter | mm | Φ78/120 | Φ78/120 | Φ78/120 |

| Maximum table length | mm | 250/350 | 250/350 | 250/350 |

| Maximum table weight | kg | 8 | 8 | 7 |

| Positioning accuracy | mm | ±0.0075 | ±0.0075 | ±0.008 |

| Repeat accuracy | mm | ±0.004 | ±0.004 | ±0.004 |

| Electric capacity | kva | 15 | 15 | 15 |

| Machine weight.(about) | t | 6 | 5.6 | 4.2 |

| Dimensions | m | 2.8*2.4*2.8 | 2.7*2.3*2.8 | 2.6*2.2*2.6 |

FAQ

Q:Who are we?

A:We are an innovation leader in the field of CNC equipment. We are a manufacturer specializing in the production of medium and large-scale high-efficiency turning centers, CNC slant-bed lathes, CNC flat lathes, machining centers, and vertical lathes. We sincerely invite global strategic partners to discuss industry trends together.

Q:How can I choose the most suitable machine?

A:Please tell me your specifications and we can choose the best model for you, or you choose the exact model.

Q:Do you have a physical factory?

A:Yes, we are a CNC lathe manufacturer in Tengzhou City, Shandong Province. We have a professional technical team, sales team and after-sales team.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF, EXW; Accepted payment currencies: USD, RMB; Accepted payment types: T/T, L/C, Western Union; Used languages: English, Chinese

Q:How do we ensure quality?

A:Pre-production samples are always carried out before mass production; final inspection is always carried out before shipment;

Q:Why should you buy from us instead of other suppliers?

A:We have been specialized in manufacturing these products for 20 years and have obtained ISO 9001 certification, CE certification and EAC certification.

Q:Can you customize the machine?

A:Yes, we integrate design and development, with experienced engineers and assembly technicians.

Q:Can I visit your factory?

A:Okay, you're very welcome.